Industry Nine Wheels: Backcountry 450 Review

So what does a high-end handbuilt wheelset really do for you? And why should ‘internal rim width’ not be taken lightly? We tested a set of Shaq-spun, ultra-wide Industry Nine Backcountry 450 wheels for over nine months to find out. Learn more in this long-term review…

PUBLISHED Jun 27, 2017

Whether building a rig for long bikepacking trips, weekend adventures, or afternoon singletrack exploits, a quality handbuilt wheelset is considered one of, if not the most, worthy of upgrades. Unfortunately, it’s also one of the costliest. But shouldn’t wheels take priority given the perpetual and rather profound nature of their duties? While mulling that over, there are a few things to consider.

Owning a super fancy wheelset is a new thing for me. I’ve had good, medium-grade wheels that were handspun by reputable builders; in turn, I’ve never lost a spoke or had to retension a wheel. The benefit of having a skilled individual — instead of a factory or machine — lace your wheels may be unclear to some, but it is very real. For starters there is a high level of quality assurance that happens when a wheel is being built by a single person. Every part and step is under scrutiny. There are also mechanical advantages to handbuilt wheels. If a spoke should come lose or break it can be replaced and trued easily. Have you ever tried to remove a spoke from a machine built wheel? Not as easy of a task as one might think. Also, stock wheels might look OK to the untrained eye, but they are often very poor quality wheelsets comprised of low-budget components. Alternatively, going the custom route allows you to handpick good components to suit how and where you ride. A well thought out, high-end wheelset has the potential to save rotational weight, add stiffness and responsiveness, increase tire performance and traction, quicken the speed of pedal engagement, allow for quick and easy service, and ensure that you keep rolling. Industry Nine wheels have made it to the shortlist of many a rider’s dream wheelsets, because they promise to tick a lot of those boxes. I9 offers a slew of custom wheels in various hub standards, configurations, diameters, and rim widths, all made onsite in their Asheville, NC facility.

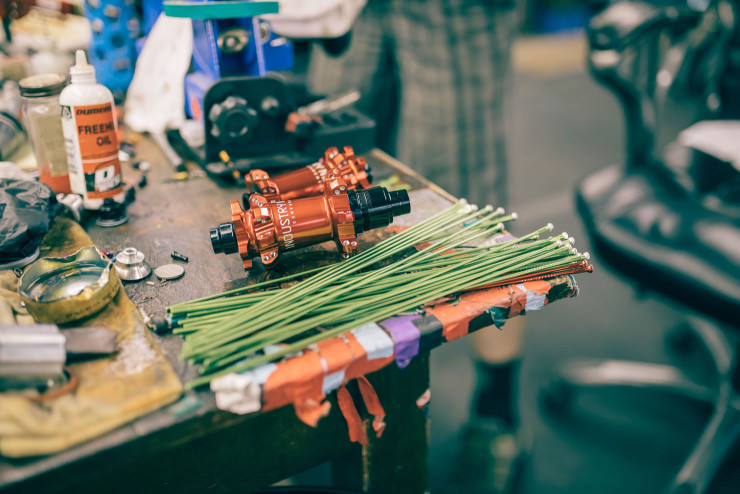

Since September I’ve had the opportunity to test a pair of their 27.5” alloy Backcountry 450 rims laced to Torch Hubs with I9’s signature aluminum spokes in anodized lime green and red. There’s no denying their good looks, but do they live up to their reputation?

It’s all in the width

Industry Nine released the wide Backcountry (BC) rims a little over a year ago. Given that plus — and now “wide trail” — tires are popular amongst bikepackers for their added floatation, forgiving volume, and sure-footed traction, it makes sense that I9 named this series with a nod to adventure. Backcountry rims are available in two widths, the BC 360 and BC 450 — each named after its internal rim width. The narrower rim, the Backcountry 360 has a 36mm inner width that’s suitable for 2.4-3.0” tires. The wider Backcountry 450 has a 45mm inner width and is designed for 2.8-3.8” tires. Both of the Backcountry rims are available for 27.5 and 29 inch configurations — the 450 weighs 600g and 640g respectively. The design of the Backcountry rims utilizes a narrow center channel and a wider bead shelf. As expected, tubeless set up with a floor pump was no problem.

In the grand scheme of things I9 nailed it with these two width options. Each yields advantages for tire sizes that are gaining momentum in the marketplace. The 360 is ideal for tires that tend toward the ‘wide trail’ category and are absolutely perfect for the newer 2.6” tire width. The 450 is at the wider end of the spectrum — a sweetspot for 3” tires. I tested the Backcountry 450s with both 3” WTB Bridger and Ranger tires and found the 45mm inner width is ideal for keeping the tire profile stable and locked in place. Granted, it might be interesting to see a 410 nestled between the 360 and 450, which would be perfect for 2.8” tires. With the growing number of tire size options, variety is a good thing; but pinpointing a perfect match is key.

Why is width so important?

When plus tire bikes originated (circa 2013/the advent of the Surly Krampus) there was essentially one rim to consider aside from Rabbit Holes — the Velocity P35. The idea being that 35mm was kind of a one size fits all that could accommodate standard 29er tires as well as 3” meats. But the internal width of the P35 was more like 30mm. It took a lot of internet arguments before folks were convinced that this is simply too narrow to get the most out of true 3” plus tires. In cutaway profile they would look like a basketball wearing a tiny beanie when mounted to Knards. To compensate and perfect the performance of bigger tires, rims became wider, and that trend trickled down beyond plus tire applications — 30mm is now widely accepted for 2.2-2.4” tires. So why is wider better? There are a lot of reasons, but in a nutshell, a wider rim provides a fuller tire profile which opens up the tire’s capabilities. This isn’t simply because a wider rim spreads out the tread to create a larger contact surface, although that’s part of it. An alternative explanation is that a wide rim creates a more vertical sidewall profile which increases lateral support, creating firmer tire contact. For bigger tires, this enables lower air pressures without the risk of burping air or having them squish and squirm when cornering. The lower tire pressure capability offers its own set of benefits, including maximizing the tread contact area, resulting in better traction and increased braking control. Some claim that running lower pressures on varied terrain actually reduces rolling resistance. All in all, matching a tire size to the perfect rim width ensures solid footing and better traction. Because of all of these benefits, rims are trending wider in every discipline, from enduro to gravel cycling.

However, some folks might argue that going too wide might make rims more susceptible to damage. Technically there is a longer perpendicular measurement from the spoke holes to the bead, making it easier to rim strike and weaker against impacts. While I haven’t had this issue, fellow site contributor Skyler Des Roches mentioned that he opts for a 40mm internal rim width with 3″ tires and feels the trade off is worth it to avoid rim strike damage. In addition, moving to a 40mm rim (vs 45) shaves off about ~60 grams, for what it’s worth. Personally, I am quite happy with the 45mm inner width and would only go to a 40mm IW rim if I were dead set on 2.8″ tires.

To summarize, sticking between 35-45mm internal rim widths allows riders to reap the most benefits out of any tire size between 2.5” and 3.25”. Even when considering 2.2-2.5” tires on a regular 29er or 27.5″ bike, simply going to a 30-35mm internal rim width will enhance ride quality and provide a lot of the benefits inherent in plus sized tires. You just need to be mindful of frame clearances and the increased tire width that results from a larger inner rim width.

Rainbow Bright and an Extra Gear

Industry Nine wheels are nothing short of iconic, especially around western North Carolina. You can spot a pair of I9s from a couple hundred yards away. Their signature is the thick, aluminum spokes anodized in one of a dozen different colors, or a mesmerizing combination thereof. It’s not all about the look though. Industry Nine spokes are 20-25% thicker than traditional steel spokes and each weighs less than a 14-gauge steel spoke, but, according to I9, has roughly the same tensile strength. Each one is a solid piece of 7075-T6 aluminum, machined, threaded, and laser engraved in the Asheville facility. I9 also claims their straight gauge spokes are stronger than traditional j-bend steel spokes, because they’ve eliminated the two main points of failure, the middle of the bend and where the metal diameter is reduced at the first thread on the nipple end. By eliminating the bend altogether, the spoke is instantly less prone to fatigue stress failure. Plus, and this I quote directly from Industry Nine, ”…the root diameter of the Industry Nine one-piece spoke thread is actually larger than the diameter of the shaft of the spoke. Other spokes fail at the first thread because the root diameter [the bottom of the thread’s “V”] is actually the smallest diameter of the spoke, just where slight relative motion of the nipple apply additional bending forces.” It’s an earful, but they are the engineers. Either way, after countless trail rides and a handful of overnight and weekend bikepacking excursions, I haven’t lost a single spoke, and these wheels are as true as the day I got them.

Before riding these wheels a local mechanic and I were chatting about them. He said “They’re unreal; it’ll feel like you added another gear to your bike.” I was particularly attuned to that claim once pointed them down the trail. Considering they were mounted on a full-squish Salsa Pony Rustler shod with 3.0” tires I thought it might be tricky to discern the stiffness and responsiveness that many people attribute to I9s. However, I can easily say that these are, by far, the most solid feeling wheels I’ve ever ridden. There was a noticeable difference in the bike’s handling and stiffness. It felt snappier in and out of corners and was easier to pick through lines with more precision, even on plus tires. The added rigidity led to me to be more particular with the tire pressure and suspension tuning to get the desired feel.

I might add that the 450s look pretty sweet too. I picked 30 “LimeGreen” spokes and two red ones for each wheel. That’s pretty tame as far as the options go, but for me that was even a little crazy. I usually lean toward the minimalistic and choose black — like my soul — or gray — like my hair. Since getting these wheels, all others with traditional skinny black spokes just seem bland… maybe I’m a changed man.

The sound of engagement

And if you can’t see Industry Nine wheels coming, you can definitely hear them. Usually that means somebody’s coasting on your rear wheel waiting to pass. That precise, tactical buzz is unique to the Torch hub freewheel and is part of what makes Industry Nine hubs some of the best and most sought after in the industry. In a nutshell, that infamous bzzzz is owed to Industry Nine’s unique 6-pawl design with 120 points of engagement. As the hub turns the pawls are phased so only three are touching the hardened steel drive ring at any given time. This results in nearly instant engagement; three degrees at the crank (most hubs are six). This may not be important to those who are puttering along dirt roads, but if any technical rocky terrain is in the mix, having a responsive, ratcheting hub allows immediate reaction to transitions requiring maneuvers. Many riders are drawn to plus bikes for their superior traction, and a rapid engagement freehub can make the most of that traction on technical climbs. This has made a huge difference to me on the Pony Rustler, given it’s low bottom bracket. Churning through ruts, roots, and rocks takes patience and finesse when timing pedal strokes. The lack of delay and quick feedback at the pedal has allowed me to better adjust and react in such situations.

The sound of the Industry Nine freehub may turn some people off. Personally, I like it and don’t really notice it that much when out on the trail. It’s crisp, mechanical, and really not that loud. It is, however, loud enough to serve a purpose… warning fellow riders and hikers alike when zipping down hill on a crowded trail. Back in the fall, my wife was sent to the hospital after a head-on collision with another rider; perhaps the extra sound of the I9 wheels she’s now riding would have prevented that accident from happening.

Some folks claim to have quieted their I9 freehub by packing it with grease — although this isn’t recommended by I9 — instead of the standard Dumonde freehub oil. You can also remove three of the pawls to make a traditional 6° engagement hub, but I have no idea why anyone would choose to go that route.

What’s Industry Nine Torch?

Industry Nine hubs have been around since 2005, but were revamped and released as the “Torch” platform in January of 2013. The main change between the “legacy” rear hub and the Torch version is the driveside bearing layout. The former design used a large driveside hub shell bearing that ran on the freehub whereas the Torch rear hub has a smaller bearing that runs on the axle. This reduced drag, and weight by about 80 grams. The other big change was to a universal axle system with swappable endcaps to accommodate the four common specs at the time (QR, 10×135, 12×135, 12×142). The Torch hubs also saw new pawl and seal design for reduced freehub drag as well as improved hub sealing for longevity. Torch hubs are now available in an dizzying array of sizes. Rear axles come in QR 135mm, 10x135mm, 12x135mm, 12x142mm, Boost 12x148mm, 12x150mm, or Super Boost 12x157mm. With the Torch release, front hubs got a universal axle system allowing for QR 100mm, 9x100mm, 15x100mm, Boost 15x110mm, Boost 20x110mm, or 15x110mm RockShox… all on one light weight hub with just the swap of the endcaps. Both front and rear hubs are available in 28 or 32-hole and in a choice of 12 anodized colors. They also come in either a 6-bolt disc or center-lock format.

Lifespan and Jay Petervary

I’m not exactly sure how many miles this wheelset has on it at this point, nor am I too concerned. They aren’t showing any signs of wear. I will likely oil the freehub soon though. According to I9 there’s no official projected lifespan on hubs as there are way too many variables. Bearings should be checked every 6-12 months. Driverings and pawls will generally last the lifespan of the wheel assuming reasonable service intervals. Industry Nine recommends the freehub should be removed, cleaned, and re-lubed every six months.

The Torch MTB hubs use 61804, 61803, and 61903 bearings, all of which are very common bike industry bearings (see exploded diagram). Average lifespan for bearings is in the 1-2 year range depending on frequency of use and conditions. The most common one to wear out is the 61803 at the freehub. It’s about the size of a stack of three quarters, so, should one be inclined to do so, carrying a spare is easy. As I mentioned, I’ve had no problems after a lot of hard use. For added validation, Jay Petervary just finished up his 2,732 mile 2017 Tour Divide on a pair of Industry Nine wheels (Industry Nine Ultra carbon rims with Torch/I9 aluminum spoke combo on the rear and a SON Dynamo on the front). To quote Jay directly from an Instagram message two days ago from somewhere near Pie Town, “Love the I9s… beating the shit out of them. No problems.” I am fairly sure that’s more miles than I have on mine, so I’m feeling pretty confident.

Speaking of service, another major plus of the Torch hubs is their tool-free serviceability. Accessing the internals is fairly simple and makes it easy to do your own oil lube, endcap swaps, or access spokes, should ht need arise. Here’s a detailed video from I9 showing how it’s done.

Like all of Industry Nine’s wheels, this particular wheelset was built with hubs and spokes machined and assembled in house, and rims made in China. It was laced by Ricky “Shaq” Muehl, a I9 wheel building veteran of about eight years. Ricky is one of six dedicated wheel builders at I9. The Backcountry 450 wheelset was provided for review by I9 and retails as shown for $1370 with the “Plus” color option (your selection of red, black, and silver, plus one color from the premium pallette). However, the same wheelset starts at $1275 if you stick with all black. Or, if you want to choose any combination of colors, the “Premium” option is $1540. The weight of the Backcountry 450s with valves and rim tape is about 925g for the front wheel and 1,095g for the rear, for a total of 2,020 grams (4.45 pounds).

Pros

- Unique and customizable wheel builds with infinite color options.

- The Backcountry rims come in two perfect widths ideal for two popular tire sizes: 450 for 3.0” tires and 360 for 2.6”.

- Stiff wheel and extremely fast engagement hub offers excellent ratcheting capabilities for technical riding.

- Handbuilt by individuals, which offers a high level of quality assurance, and other benefits.

- Hubs and spokes are made in the USA.

- The latest Torch hubs are considered extremely reliable. Plus the press fit design offers easy, tool-free serviceability.

- Narrow channel design makes tubeless setup easy.

Cons

- They are louder than most other hubs. I am playing devil’s advocate though… to me this isn’t a con.

- Spokes are proprietary, which may not be considered ideal for long international trips. I9 does include spare spokes to carry should you set out on a big trip.

- Expensive for an alloy wheelset. But, considering that the hubs are some of the best in class (and made in the USA), you get what you pay for.

- The rims are made in China due to the machinery and expertise required. Should you want USA made rims to lace with I9 spokes and hubs, that’s possible too. Enve and Velocity both make rims in the US.

- Model tested Industry Nine Wheels, Backcountry 450, 27.5 BOOST

- Price, as tested $1370

- Weight (front) 925g (2.00 pounds)

- Weight (rear) 1095g (2.41 pounds)

- Weight (total) 2,020 grams (4.45 pounds)

- Contact IndustryNine.com

Wrap Up

There isn’t much not to like about Industry Nine wheels. Some folks might take issue with their unique sound, and they aren’t cheap. But there is a lot to be said for the fact that the hubs and spokes are made in-house in Asheville, NC, and each wheelset is handbuilt by one of six people who are damn good at building wheels. In addition, switching to Industry Nine Torch hubs has been an enlightening experience as to how a hub should be; fast, light, easy to service, and nice to look at too. I’m also happy with the BC450 rims. They proved easy to set up and feature a tall, angled rim profile likely adds leverage to help stiffen and strengthen the wheel.

In my opinion, a wheelset upgrade is one of the best investments you can make when it comes to ride performance. Industry Nine’s combination of a 3° engagement hub, aluminum spokes, superior in-house builds, and quality rims makes Industry Nine wheels some of the stiffest, quickest, and most reliable on the market. And, if you are in to wide tires, the Backcountry 450 is the the perfect width for 3” tires. I’m sold.

To find out how these wheels were made, and more about the company, make sure to check out our Industry Nine site visit article (from September 2016; published January 2017).

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.

We're independent

and member-supported.

Join the Bikepacking Collective to make our work possible: