A Day with Black Sheep Bikes in Fort Collins, Colorado

Share This

We recently asked photographer Josh Hicks to swing by Black Sheep Bikes in Fort Collins, Colorado, where he got to know founder James Bleakley and put together an illuminating video and fantastic gallery of photos. Find Josh’s video interview with James and a detailed look inside the celebrated custom titanium builder’s shop here…

Words, photos, and video by Josh Hicks (@joshhicksss)

Before moving to Colorado last summer, I’d heard stories and seen photos of the curvy, mind-bending titanium artwork that Fort Collins, Colorado-based Black Sheep Bikes has become well known for. Diving deeper, I figured they must be some kind of magicians to be able to create something so unique and functional.

And then I found a 26” Black Sheep hardtail titanium frame on Craigslist that James Bleakley, the founder and owner of Black Sheep, made somewhere around the mid-2000s, and I walked into his shop asking if he could weld on a disc tab, bend custom bars, and sell me a matching rigid titanium fork. I realized instantly that James was more than a mere magician. He’s also a kind, open, and overall humble person who has been highly regarded in the industry since before I was born.

The year was 1991 when he got his first job in the world of bikes. Boulder Bicycles hired James to help with shipping and receiving of their frames. Eventually, he worked his way up through ordering materials, to assembly and machining, all the way to becoming a welder for their steel frames. He describes beginning to weld as the moment everything clicked for him; creating bicycles from raw tubes through welding would become his biggest passion in work.

A few years went by, and the feeling of not having a “sustainable career” in the eyes of society brought pressure on James. He decided to take an opportunity to provide more for his family at a nearby company called Advanced Alloys, where he helped build fine-tolerance weldments for the medical, helicopter, robotic, cryogenic, and computer industries. Ultimately, he grew tired of the longer commute and decided to take a risk and open Black Sheep Bikes in 1998.

In the early days of his own company, he took on welding jobs outside of bikes to help pay the bills. This included making custom furniture, but the bulk of his bottom line came from contract fabrication for DEAN Bicycles in Boulder and custom tandem maker da Vinci Designs in Denver. Between 2000 and 2008, he made around 3,500 to 4,000 frames for DEAN and about 700 tandems for da Vinci.

The name of his new company came to him years earlier at a mountain bike race where he was wrenching for Boulder Bikes at Big Bear. He was in the pit area working out of a beat-up old Econoline van, just next to the fully decked-out and custom-painted vans from pinnacle brands of the 1990s mountain bike culture, such as Ringle and Yeti Cycles, among others. One of the racers pulled up and said, “Wow, we really are the black sheep!” That phrase resonated with James, and he put it in his back pocket as a potential name for a company.

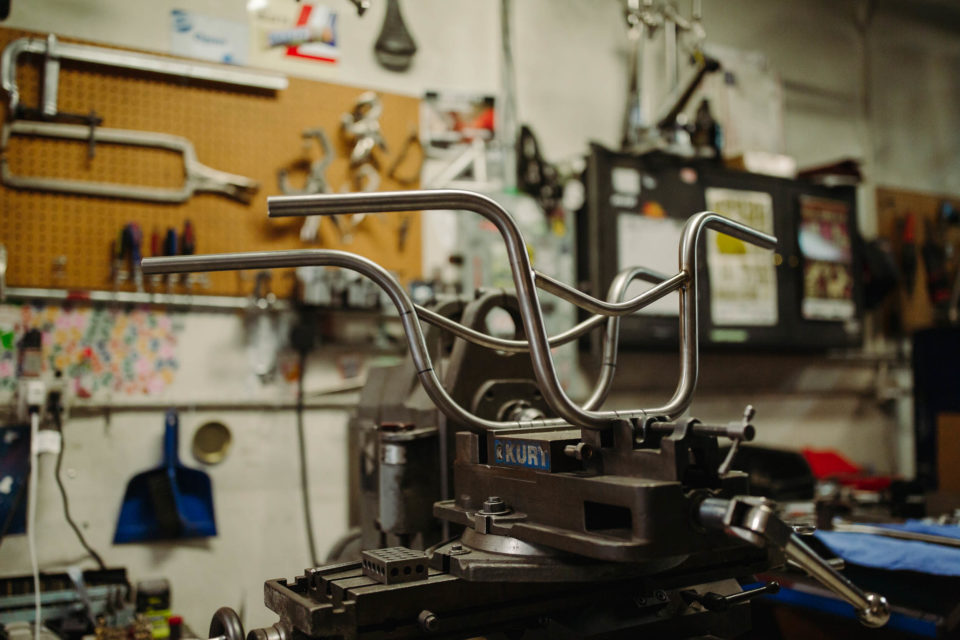

Almost 30 years later, James now works in his shop with his son Tarryn producing about 75 custom frames a year. Titanium is their material of choice, all the way down to custom handlebars, stems, forks, and even racks. The most common builds they’re making for customers are gravel, all-road, mountain, klunker and fat bike frames. However, James is also uniquely known for creating BMX, tandem, 36ers, unicycles, cargo, and other specialty bikes. Most of the frames have some sort of custom curve to them, sized to fit each frame’s rider. Within the swoopy tubes, James believes in function over form, with each bend bringing a bit more compliance and dampening than a straight tube.

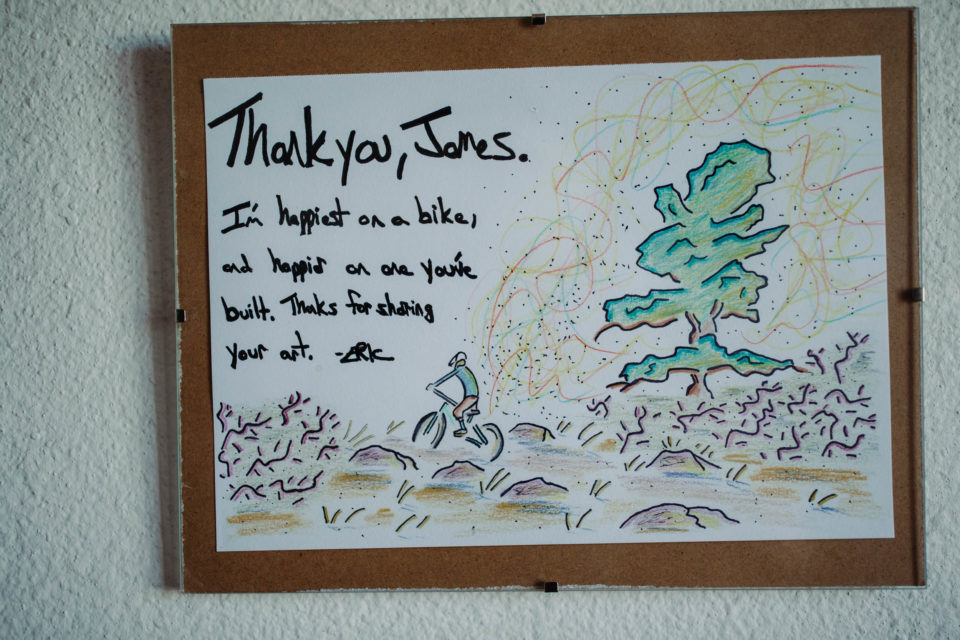

Walking around in the shop, it’s an endless smell of ground metal and fumes from the welder (and of course the espresso machine too). Minutes go by, and I find myself staring at bikes hanging from the ceiling; there are several from the 90s all the way to full-suspension and BMX. Stickers cover the entire refrigerator, large portions of cabinets, and the walls, each one from a brand or race they’ve encountered over the years. Thank you letters and drawings hang in the front office, as do trophies and magazine features. Photos from adventuring on two wheels, typical bike industry humor, prototype frame drawings, random creations like the dinosaur made from a stem/brake levers, and other bits are some of my favorite sightings amid the many small treasures scattered throughout the space.

Black Sheep Bikes has won more than 10 awards at the North American Handmade Bicycle Show (NAHBS), including Best Titanium Bicycle, Best Tig Construction, and Best Artisan Bike three years in a row. There are truly no two frames alike when it comes to the work James creates. Every frame gets a custom head badge from Jen Green. You can choose from several casts or create something totally new, such as the sheep picking up a Yeti from a UFO.

Titanium has been his material of choice due to the space-grade metal’s characteristics. He explained that it holds 20% elongation, allowing the bends he creates to maximize smooth and subtle vibration dampening that steel and aluminum simply can’t reach. Titanium is also extremely lightweight, non-corrosive, and doesn’t need paint for protection. The biggest challenge, however, is its soaring cost. For this reason, James now has a line of production-sized steel frames called the Roots line for a more affordable entry into modern geometry frames.

One of the stories I enjoyed most during my day in the shop was talking about riding the Leadville 100 on his single-speed coaster brake klunker. No front brake; traditional old-school mountain biking in its early days. As James put it, “I had moments of absolute terror. You’re looking at the turn ahead of the turn and planning how to set up for both without hitting the brake since it’s really only on or off, losing all traction and speed while going downhill on switchbacks. It’s kind of a continual ‘oh shit’ moment of full commitment forcing extra pedal strokes to line up the inside pedal to make the corner.” Several years ago, he earned his 1,000-mile belt buckle, having completed the 103-mile course a dozen times—all aboard a single speed.

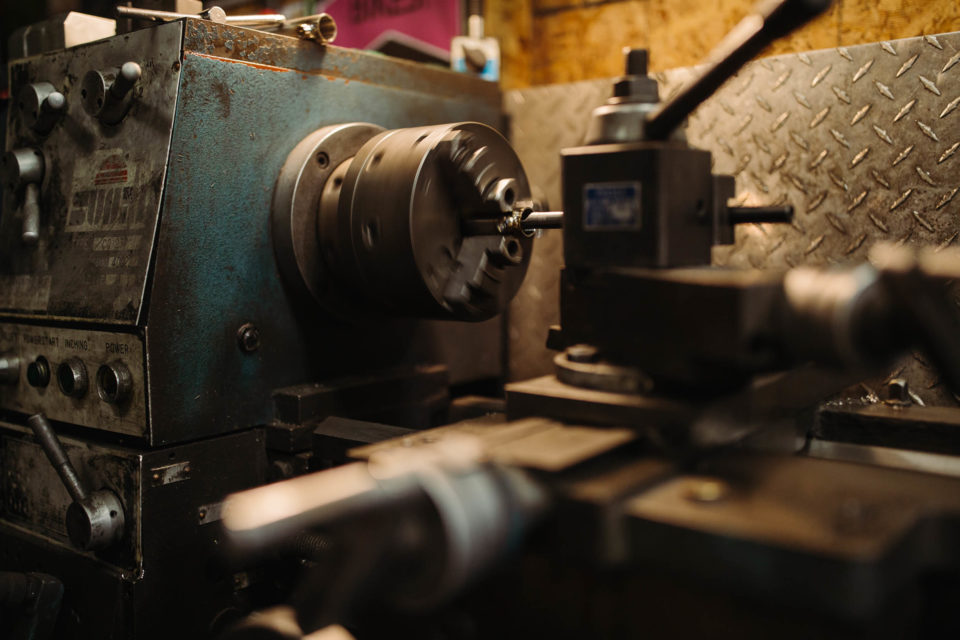

We spent time talking about his custom one-piece bar/stem combo that are also known as “nine piece one piece” due to perfecting construction for symmetrical flare and sweep. They make small bits on the lathe to weld inside the bar where the drops are later attached and have a brace in the center, sometimes big enough to fit a handlebar bag within. Another component of absolute creativity are the titanium forks and racks they create for frames made in house. James has been able to get almost 2” of travel out of his rigid Deathplosion fork paired with a wide mountain bar. He’s also made fat bike forks in the past with a 100mm Fox shock in them with aluminum linkage, weighing in at six pounds. Designed right, titanium is a system that allows for a rigid bike with passive suspension, non-moving parts, and nothing to service annually.

James also makes a truss fork, modeled after the styling found on 1930s motorcycles, with a double or triple set of thin, curving legs that also address issues with fork failures. With failure usually occurring at the crown, James designed this fork to have a collar both above and below the headtube. The truss doesn’t shudder under hard braking, and serves to stiffen the front end without adding weight.

Throughout the day, James was also working on rear racks for several soft-tail mountain frames. These racks are only made for the frames he builds and are a perfect feature to top off an entire build ready for adventure. Starting with one strand of titanium, he cuts the middle support arms for the rack, bends them, and preps the edges. After that, he cuts and bends the main two outside pieces that come to a point in the front and are almost wing shaped at the back. All of the pieces are then welded, and the rack is blasted, sanded, and then fit for the support legs. He adds a slight bend—just enough to break the eye sight of straight—and tack welds into place. The entire rack is removable, using common mounts found on most bikepacking or touring frames.

Other curiosities can be seen around the shop on a typical day, such as Tarryn’s commuter he built out of strictly leftover or chopped up tubes from other frames, as well as a twin top tube frame featuring the truss fork with 32” wheels and tires from a unicycle company, and a new bar on a gravel bike that keeps the drops where the rider needs them but adds a higher hand position much like a flat bar.

Regardless of what’s happening on any given day, the shop at Black Sheep Bikes is always a pleasure to see in action. As most custom builders can agree on, James feels the usual awkwardness of being in the spotlight because of his work. I found an easy comfort with both James and Tarryn just talking about real-life moments: what’s new, thoughts on this and that, and so forth. These two at Black Sheep Bikes are a real joy to spend time with, and if you ever see them out of the trail or around town, don’t miss the opportunity to stop for a chat with them, as you’ll surely leave the interaction feeling enriched in some way.

Related Content

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.