Made in Minnesota: A Visit to Wolf Tooth Components

Share This

While visiting Minnesota over the summer, we dropped into Wolf Tooth Components HQ in Minneapolis to learn more about the company and their expansive line of US-made bicycle bits. Find our conversation with the team and a photo tour of their facility here…

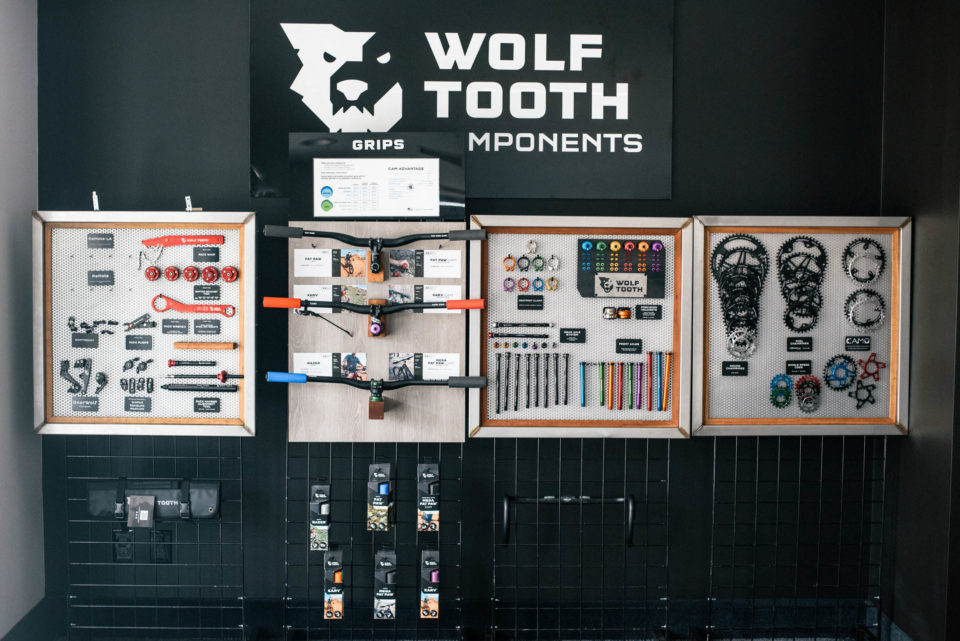

Since launching from a basement with a single chainring seven years ago, Minneapolis-based Wolf Tooth Components has rapidly grown and become well known for their ever-broadening range of innovative and often colorful bicycle accessories—from headsets, to tools, to problem-solving small parts, and lots more. They’ve been busy making their mark on the industry and show no signs of slowing down. What’s more, they’ve also spun off an in-house bike brand, Otso (see my review of the Otso Warakin Titanium), and a second components company, Lithic, along the way.

While visiting Minnesota over the summer, I spent an afternoon at Wolf Tooth HQ to take an extended tour, learn more about their manufacturing process, and chat with members of the team. Read on for my interview with Wolf Tooth’s marketing manager, Kurt Stafki, and co-owners, Dan Dittmer and Mike Pfeiffer, alongside a look at the sprawling facility in which most of their components are made.

When and how did Wolf Tooth Components get started?

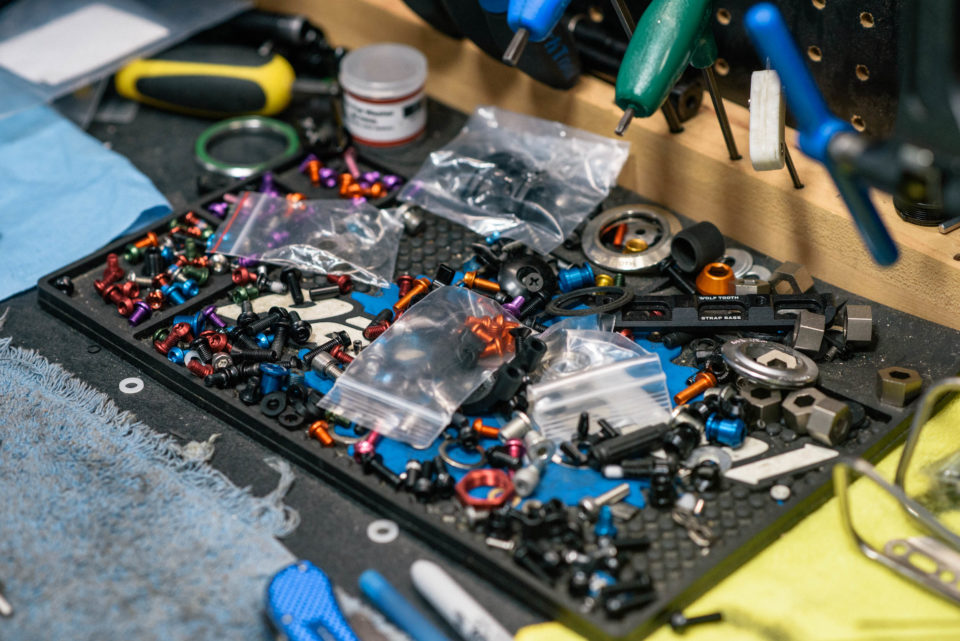

Dan: Wolf Tooth was started in 2013 by three mechanical engineers working at a local tech company. Mike Pfeiffer had an idea for an innovative new chainring and began our whole business in his basement. He shared the first one on an online mountain bike forum and sales immediately took off. By 2014, the three of us—Brendan Moore being the third—had to quit our day jobs to keep up with Wolf Tooth business. We’ve since expanded far beyond chainrings to make headsets, multi-tools, dropper levers, grips, tools, accessories, and more.

Can you briefly introduce your other in-house brands?

Kurt: We created Otso Cycles in 2016 as a way to extend our emphasis on precision design and versatility to bike frames. Otso has a small (but growing!) roster of gravel bikes and a fat bike, with more to come. Lithic was created around the same time as Otso because we needed forks, handlebars, and fat bike rims for Otso bikes in specifications that didn’t yet exist. It made the most sense to design these components on our own and launch a new brand around them.

Tell us about your current facility and what goes on there.

Kurt: We operate in a 30,000 sq. ft. facility in Burnsville, Minnesota. It’s about 20 miles south of downtown Minneapolis. The complete product lifecycle happens here: design, prototype creation, testing, manufacturing, assembly, and shipping. We have an exceptional team of about 30 people who keep our operation running smoothly day in and day out.

What kinds of roles are those 30 team members in?

Kurt: Our 30 employees are responsible for keeping Wolf Tooth running. We’re a small company, which means many of us are generalists—doing lots of things beyond what was listed on our job descriptions. We have engineers that are focused on product design and development. Our engineers spend their time brainstorming product ideas, drafting designs, working with machinists to take ideas from paper to production, and extensive testing. The machine shop team is responsible for applying designs to raw materials. They work closely with our engineers, oversee machine operation, meticulously measure products in all stages of production, and prepare items to be sent to our warehouse team for sales. Our warehouse team manages inventory, assembles products, packages items, and fulfills and ships orders. We also have employees in our office that do everything from accounting, to marketing, to graphic design, to sales, to operations, and more.

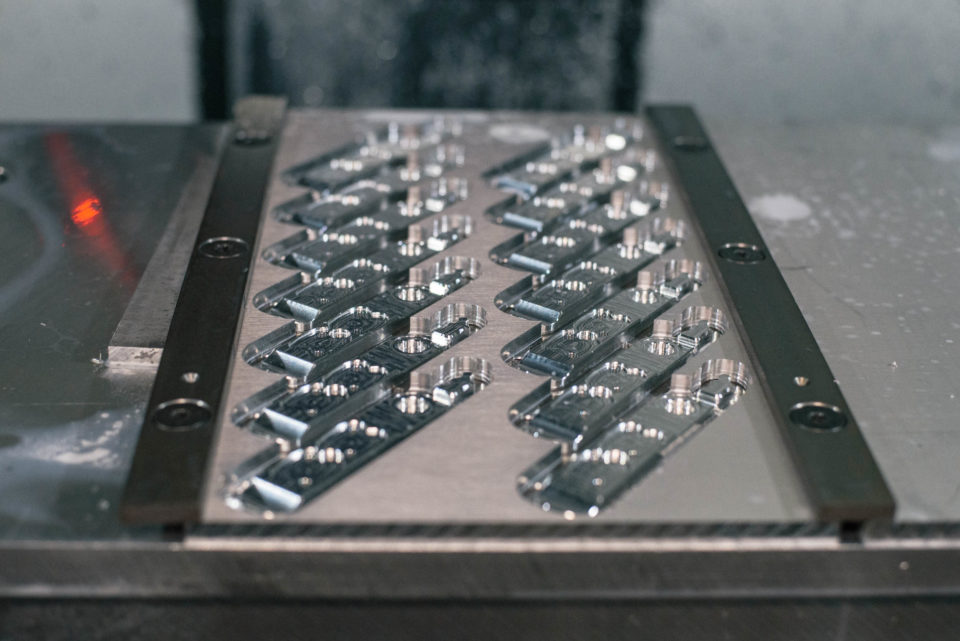

How about your machinery? What are you using for manufacturing?

Kurt: For vertical mills, we have four Haas DT-2s, one Brother SX1000, and a Kira DM43VCD. For turning centers (lathes), we have two Doosan Puma 220s and one Tsugami M08SY.

What are the biggest challenges of manufacturing in the US?

Dan: It can be very challenging to keep up with the lower manufacturing costs that are available overseas. Also, since so much manufacturing has been moved outside the US, it can sometimes be difficult to find good access to support services like anodizing, plating, material distributors, etc., as well. We’ve been able to overcome these challenges by being smart about manufacturing processes. We’re also fortunate to have a lot of manufacturing businesses in the surrounding Minneapolis area, so we’ve been able to find great local partners to provide most things we need to keep our business going.

Mike: Manufacturing requires a skilled workforce, significant floorspace, and a huge investment in equipment. We purchased our first CNC machine five years ago and we now have nine of them. I feel like we’re just now finally at the point where we have the people, machines, and product volume to make US manufacturing really competitive.

And the biggest rewards?

Dan: It’s incredible to see a product go from design to a finished item in one building and to personally know everyone involved in the process. That helps us stay nimble and bring products to market much quicker than companies that manufacture overseas. It’s invaluable for the engineers designing a new product to be able to talk to the machinist who will be making the product, or for the customer service person to be able to talk to the people who designed and machined the products.

Mike: It’s great to be creating jobs in our community, and moreover to be creating cycling-related jobs outside of retail.

What do you think sets Wolf Tooth Components’ products apart from other similar offerings on the market?

Dan: We try hard to always have something unique and innovative in our products compared to market competitors. We’ve also never been afraid to make a product for niche applications. We’ve learned that if we have an idea about something that solves a problem that bugs us when we’re riding, there are probably other riders who are looking for a solution for the same problem. One of the benefits of manufacturing in small batches is that you can take chances on niche products that large companies would never consider.

What Wolf Tooth product are you most proud of?

Dan: We have so many products that make my riding experience better, but if I had to pick one, it would be the Pack Pliers. When I look at the product now it seems so simple, clean, and obvious, but it took several years and dozens of prototypes to develop. What I’m most proud of is that the final product incorporates ideas and feedback from so many different people in the company. The final product is far better than any one person could have come up with on their own.

Outside of the cycling world, where does your design inspiration come from?

Dan: Passion for cycling runs deep in our company, but we’re always looking for ideas and inspiration from the larger outdoor sports world in camping, climbing, motocross, automotive, and beyond. The founders of the company came from the tech industry doing precision high volume manufacturing. Wolf Tooth manufacturers products in much smaller batches but many of the design principles from the tech world can be applied to make cycling components more functional, consistent, and reliable.

On a given day, what kind of bikes are in the employee parking rack?

Kurt: It’s a healthy mix of mountain bikes, fat bikes, gravel bikes, and a road bike or two. Some employees are geared up for 40-mile round trip commutes, while others take advantage of the mountain bike trail networks that are within short riding distance from our shop. We have lots of employees riding in and out all year long.

Any new products in development that we can know about?

Kurt: We’ve got a fun spin on our Pack Pliers that we’re all quite excited about. Expect to see this new multi-tool in the fall.

Mike: We have our biggest product launch ever coming up sometime in the spring of 2021. It’s going to be pretty exciting!

What’s your favorite local trail or place to ride?

Kurt: We’re lucky to be surrounded by local MTB trails and be close to an endless network of gravel roads. Many of us enjoy the River Bottoms, a network of trails that begin near the confluence of the Mississippi and Minnesota Rivers in the heart of Minneapolis/St. Paul and extends many, many miles up the Minnesota River. It’s a fun, secluded area with lots of wildlife in a floodplain that creates dynamic trail conditions all year.

Mike: I love riding anywhere in the Northwoods. Duluth, Minnesota, and Cable, Wisconsin, are my two favorites that could be considered “local.”

Finally, what else should readers know about Wolf Tooth Components?

Dan: It’s probably a cliche, but we are a group of passionate cyclists who truly love riding and we hope that shows in our products and the way we interact with our customers.

Mike: We love to design new products to make cycling more enjoyable. We are proud to be creating new jobs in our community and manufacturing most of our products not just in the US, but in our own shop.

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.