76 Projects Hi Flow ‘No Clog’ Tubeless Valves Review + High-Flow Valve Shootout

Share This

UK-based 76 Projects Hi Flow ‘No Clog’ Tubeless Valves claim to let four times the air through compared to standard valves and use a unique core design that helps prevent sealant build-up. We’ve been testing a pair over the last few months, and you can find our complete review plus a high-flow valve shootout here…

It turns out the Fillmore Valves from Reserve Wheels that were announced just a few months ago weren’t the only “high flow, no clog” tubeless valves out there. In fact, we were quite surprised to learn that the Fillmore Valves’ tagline “Hi Flow, No Clog” is actually the exact same name as that of 76 Projects’ tubeless valves. Coincidence or not, it’s clear that more than a few brands have set out to design a better tubeless valve. Namely, something that won’t clog and has better air flow over traditional Presta valves.

UK-based 76 Projects specializes in computer mounts and on bike storage solutions. Released a few months before Reserve Wheels announced their valves, the Hi Flow ‘No Clog’ Tubeless Valves are quite a departure from the rest of their products. Up until now, 76 Projects hasn’t designed anything wheel-related, which is possibly why their valves went relatively unnoticed at the time of their launch.

So, why do we need high-flow tubeless valves? Simply put, traditional Presta valves weren’t designed with tubeless setups in mind. Tubeless sealant manufacturers are constantly developing new brews that claim to plug larger and larger holes, which in turn can wreak havoc on the small clearances found inside Presta valves. It’s really only a matter of time until tubeless sealant finds its way inside the valve, restricting airflow and the ability of the core to properly seal. The new generation of valves, including 76 Project’s, have redesigned the internals of the valve to allow better airflow and increased clearances to address these issues. Plus, they often make tubeless setups even easier to accomplish using a basic floor pump, which is great news for the home mechanic.

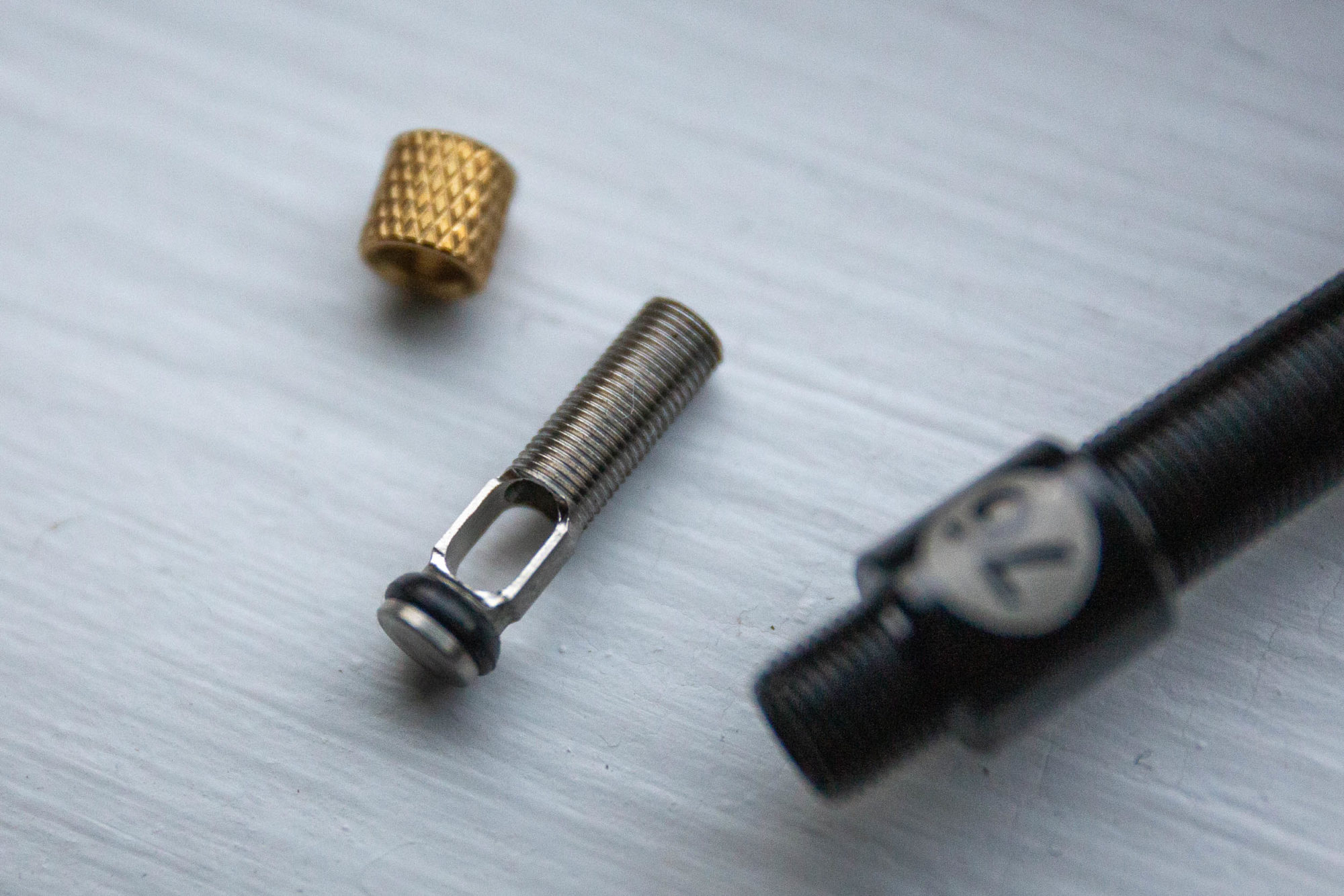

76 Projects’ Hi Flow ‘No Clog’ Tubeless Valves share the same basic shape as a traditional Presta valve but the internals are quite different. Starting at the top, the core itself of the valve is hollow, contributing to better air flow and the ability to add sealant directly through the valve, though it’s worth noting that 76 Projects doesn’t recommend doing this with sealant with larger particles, so it might be best to avoid that. The wider portion of the body houses the part that seals when under pressure, and it doesn’t restrict air flow when open. The base of the valve is also different, allowing air to pass through two slits on either side of the threaded base, rather than the small hole found on most standard valves—a design similar to what we’ve seen introduced on valves designed to work better with tire inserts.

As you can see above, the valve core is only threaded to accept the knurled brass top nut and is simply pressed down inside the body of the valve. When the valve core is pressed (open), air travels through the body, into the wide portion of the valve and around the valve core’s o-ring, and finally out through the hollow portion of the core. It might seem somewhat complicated, but the result is a valve with more airflow, as advertised.

Installation is where things get a little finicky. Due to the wide section of the valve body, the valve isn’t pushed through the inside of the rim like most tubeless valves. Instead, the bottom of the valve unthreads, the rubber gasket is removed, and the valve is inserted from the outside. 76 Projects includes several plastic spacers to accommodate different rim heights since the body isn’t threaded all the way down, and they’re offered in three different lengths as well. I was sent the shortest of the three, and on a 17mm tall rim, the valves required three plastic spacers in order to tighten up properly. The result isn’t the cleanest-looking setup in my opinion, and it would be nice to see a more elegant solution here.

As one might imagine, the increased airflow assisted with a quick floor pump tubeless setup and provided some confidence heading out on a week-long bikepacking trip on a new bike. The airflow is noticeable enough that for someone who’ll go to great lengths avoiding needing to go to a bike shop every time I mount a tubeless tire, I was pretty much sold. It wasn’t long ago when I thought titanium valves with a larger through-hole was as good as it was going to get.

The photos above show what the valves looked like after over a month of riding, including my scouting mission on the recently published Queen’s Ransom route in Arizona. A few things stand out for me. First, there was virtually no sealant inside the valve and the base inside the tire was surprisingly clean. I think the large openings play a major part in this, but I also think the height (which I’d considered a negative at first) also helps keep the valve clear of obstructions. Still, the base of the valve sits noticeably higher than any other valve I’ve used. I compared its position against valves from Reserve Wheels, Terske, and Cush Core, and the base is at least a few millimeters taller. I don’t think this would ever be an issue, since it still sits below the rim wall, but it could be on super shallow rims.

At the moment, spare parts to rebuild or repair the valves aren’t available online but can be requested via email from 76 Projects. The valve also requires an adapter, available to purchase separately, for thread-on style pumps. I don’t necessarily think having to purchase an adapter is a dealbreaker, but it’s just another little piece you’ll likely need to make sure you have with you. I’m a big fan of the thread-on Lezyne Micro Floor Driver pump but try to avoid adapters when possible. You’ll also probably notice that the valves are sold out all over, but we were assured that stock is on the way. There should be valves arriving at their UK warehouse this week, followed by their US, EU, and Canadian distributors a few weeks after that.

High-Flow Tubeless Valve Shootout

In the name of science and progress, Justin (of TAWS Bike Garage here in Powell River) and I spent some time designing a staggeringly accurate way to compare the airflow between different valves. Heavily inspired by Reserve Wheels’ test, we secured balloons onto the base of four different valves, inflated them to an equal (+/- 5%) size, and opened each valve to see which balloon emptied the quickest. The valves in question? 76 Projects Hi Flow ‘No Clog’ Tubeless Valves (~$33), Terske Titanium Tubeless Valves ($39.95), Reserve Fillmore Tubeless Valves ($49.95), and a standard generic Presta valve (~$10). Pictured in order below.

Our findings? The valves from 76 Projects and Reserve Wheels both performed far better than the standard Presta valve and the Terske Titanium Valve. The two frontrunners were close, but we both agreed that the Reserve Fillmore valves had slightly better airflow, which was actually a little surprising considering 76 Projects claims to have four times more airflow than a standard valve and Reserve claims to only have three times more. In the real world, it doesn’t really matter at all, but the main takeaway is that the unique designs from 76 Projects and Reserve Wheels do indeed work. Better airflow means easier tubeless setups at home and less sealant clogging down the road and a more reliable tubeless setup.

You better believe we didn’t just stop there. Basic balloons weren’t cutting it, so I scavenged the local dollar stores for some aerospace-grade animal balloons instead. We were able to pump them up with some pretty serious pressure, so the results were even easier to see. Once again, the Reserve Fillmore valves came out on top, followed by 76 Projects’, and then a close tie between the other two. It’s pretty clear that valves designed to offer better airflow perform as claimed, and it took a redesign of the valve core itself to make it happen.

Pros

- Better airflow than standard Presta valves

- Completely rebuildable for cleaning and maintenance

- Competitively priced at £24.50/pair

- Three sizes to choose from

- CNC machined and uniquely designed

- Compatible with tire inserts

Cons

- Shallow rims may require several spacers, which doesn’t look great

- High-profile base, compared to other valves

- Valve core is susceptible to ingress if rubber cap is lost

- Requires adapter for thread-on pumps

- Material: CNC machined aluminum

- Weight: 4 grams per valve (size 1/no spacers)

- Place of Manufacture: Taiwan

- Price: £24.50/pair (~$33 USD)

- Manufacturer’s Details: 76Projects.com

Wrap Up

I had way too much fun putting this review together, and a huge shoutout goes to Justin at TAWS here in Powell River for nerding out on valves with me. I expect anyone who hasn’t had any issues with clogging valves or pesky tubeless setups won’t see the benefits of high-flow valves like the ones from 76 Projects. However, as sealants continue to improve, it’s only a matter of time before everyone running standard Presta valves starts to have issues. I’ve had more than a few occasions recently when the valve core became sticky, making it nearly impossible to close without losing air and difficult to add air as well.

Overall, I’ve been impressed by the 76 Projects Hi Flow ‘No Clog’ Tubeless Valves. The CNC machining is clean, the clever valve core design is unique and functional, and they do in fact provide better airflow over traditional valves. I’m not a big fan of the plastic spacers that some rims will require, resulting in what I consider to be a pretty messy-looking installation, but otherwise, they do what they were designed to do, and they do it well.

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.