Reserve Fillmore Tubeless Valves Review

Just announced, the new Fillmore tubeless valve from Reserve Wheels aims to triple the airflow, never clog, and ultimately replace standard Presta valves. We’ve been testing a pair over the last couple of months for this review. Spoiler alert (before you skip a seemingly boring tubeless valve review), these things are a game-changer…

PUBLISHED Nov 4, 2021

Quite a few types of air valves have come along since the advent of the pneumatic tire. Obviously, the two that triumphed in cycling are Schrader and Presta, the latter being the one most of us use on a day-to-day basis. The Presta valve was invented in the 1920s by Frenchman Etienne Sclaverand and was commonly referred to as the “French valve.” Its formal name, however, came from the idea that these valves were presta or presto, meaning quick or fast.

While some might argue that the Presta valve is more cumbersome to use than a Schrader—since you have to manually screw the outer nut to permit airflow in either direction—it gained popularity for its advantage of being more user-friendly for quick, on-the-go inflation. In short, the springless threaded valve legitimized hoseless portable pumps that were smaller and easier to use than those required to engage the spring on a Schrader valve at the time. However, the main reason Presta valves found success is arguably because they require a smaller mounting hole in the rim, enabling narrower rims that could maintain the same level of strength (technically, the weakest point of a rim is at the valve hole). Either way, the Presta valve became the dominant choice in road racing bicycles, ultimately prevailing as the norm in most cycling disciplines.

Presta valves haven’t really changed that much after all this time. A lot of variations have toyed with different lengths, locknut shapes and sizes, and other such minor alterations. And there was one big shift that paved the way for tubeless valves—the removable core, which has become a standard inclusion on almost all Presta valves since somewhere in the mid-2010s. However, the latest innovation does away with the removable core and overhauls the Presta valve from the ground up, creating a new type of valve that’s different from anything we’ve seen, and in fact not like a standard Presta valve at all. Read on for our review of the new Fillmore valve by Reserve Wheels.

The Fillmore tubeless valve was created by Reserve Wheels, a company founded in 2014 by a couple of engineers from Santa Cruz Bicycles. Reserve makes high-end carbon wheels that can often be found on many of Santa Cruz’s upper-tier builds, added onto bikes as an upgrade, or purchased separately. So, why would such a company try to reinvent the Presta Valve? It was really only a matter of time. The smaller diameter stems that made Presta valves the norm back in the day are now kind of a catch 22, as rims are wider and most tires are tubeless, and they use sealant that’s designed to plug holes bigger than the airway within Presta valve cores. Therefore, sealant clogs have become the new norm. Additionally, the poor airflow that comes hand in hand with Presta valve cores makes it challenging (and sometimes impossible) to get enough air through to seat the bead and set up a tubeless tire. Often you have to remove the valve core to accomplish this, then replace it and reinflate, particularly if you’re tackling a tubeless setup without an air compressor. Fillmore tubeless valves were created to change all of that. “High Flow and No Clog” is their tagline, as a matter of fact. And with a revolutionary design, they promise three times the amount of airflow—and zero clogs.

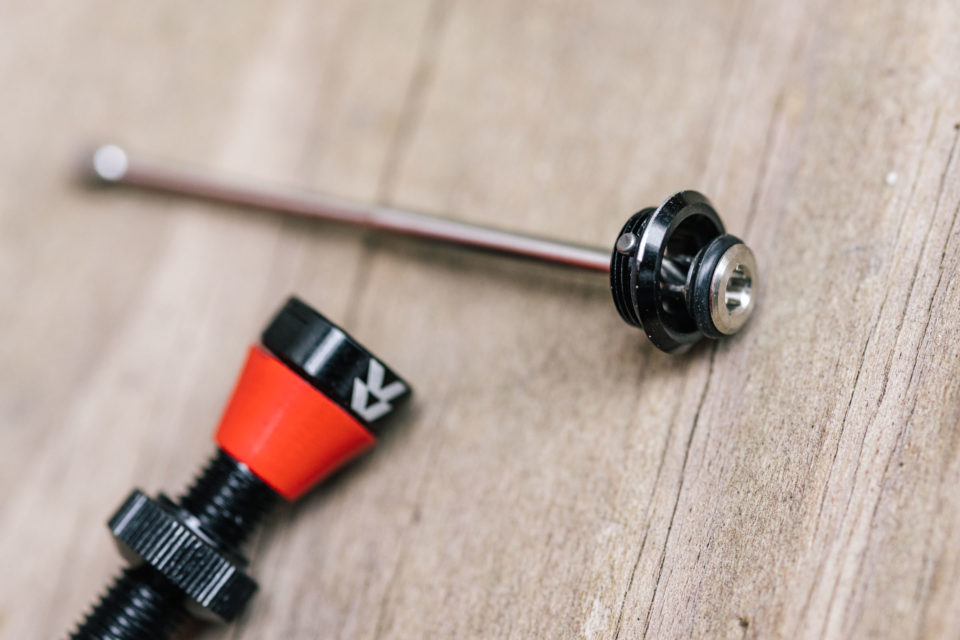

The Fillmore tubeless valve works using a poppet valve. Most commonly used to control gas or vapor, a poppet valve consists of an aperture that is opened and closed by raising and lowering a disc-shaped seal onto the opening. In this case, the opening is at the valve’s base, inside the rim, so when it’s closed, no sealant can penetrate the valve stem. And when it’s opened, the air volume is unencumbered by a core or other parts. The Fillmore accomplishes this by using a single steel plunger with an O-ring that’s pulled onto the valve base when the cap is tightened. It’s also pushed into place with air pressure, which I’ll dig into later. This seemingly simple system works remarkably well.

Before I get into how exactly the Fillmore performed, let’s address the elephant in the room to avoid everyone diving straight into the comments to type, “$49 for a pair of valves. No thanks!” These things are expensive. All I can hope is that they last forever because they are a game-changer when it comes to function. They do have a Lifetime Guarantee, but still, you might expect there to be titanium inside these things at that price point. There isn’t, but there is a lot that makes them tick (not that it completely justifies that high price tag). The Fillmore valve is technically made up of nine intricate parts. On the outside, there’s the machined alloy stem, threaded clamping nut, rubber/silicon bushing, and the knurled cap. However, with a 2.5mm Allen key and a 10mm open-ended wrench, you can unscrew the base of the valve stem at the large end and pull out the steel pin. As you can see in the photos below, the steel interior pin is permanently fixed to the end cap with a tiny steel rod. Lastly, there are two O-rings: one that makes the poppet seal and another inside the end-cap that presumably keeps it from leaking air. It’s a pretty ingenious design and there’s a lot of delicate machining that went into these little gizmos.

Fillmore Tubeless Valves, In Use

I first used my pair of Fillmores to seat a fresh pair of trail tires on my Industry Nine Enduro S wheels. Typically, I would have had to remove the valve core in the Presta valve and charge the air chamber in my fancy tubeless pump. This would provide the blast of air needed to push past the small (and probably semi-clogged) valve base to seat the tire bead onto the rim. With the Fillmores, I simply pumped it three or four times in quick succession and it caught and seated immediately, no problem. That checked off one major advantage of the Fillmore’s design. This was probably the easiest and best experience I’ve had setting up tubeless tires in my career.

The second benefit that Reserve touts about the Fillmore’s design is the ability to precisely bleed air using the cap. This means that if you unscrew the cap a few turns, you can then simply tap or press it to let air out of the tire in a controlled manner. This is a handy feature if you’re constantly tuning your tire pressure based on the terrain. I honestly didn’t use it much during the two months I’ve been testing the valves, but it’s a nice touch.

One of the concerns I initially had was losing a cap. I didn’t, but I wondered what would happen. To give it a go, I took the cap off the Fillmore on my front wheel and went out for a rugged trail ride here in Pisgah. I’m happy to report that zero air leaked after a very rough, rocky, and rooty 12-mile test ride. So, the short answer is that you can get by if you lose a cap. However, I might worry about dirt and sand getting into the valve stem over time since there’s a significant opening there. I suppose you could just put some Gorilla tape on it in a pinch.

Along those lines, I also might be somewhat concerned with another potential point of failure on a long-term ride: the O-ring seal. If it fails, you’re kind of screwed. I can’t imagine what would cause it to fail, but things break down over time, so you never know. I hope Reserve sells replacement caps and O-rings as I would likely carry a spare of each on any bikepacking trip longer than a month or so.

Adding sealant was another concern. Technically, the main pin remains in the valve unless you remove the entire assembly to clean it, so you have to push sealant through it and around the poppet valve. I did it using an old Orange Seal bottle with the sealant hose. It worked fine, and once you pump the tire back up, the fast flowing air seems to clean out the residual sealant that went through the valve. Since it’s not often that you have to add sealant, I don’t see too many issues with it getting clogged. If you were really concerned about it, you could theoretically run a quarter ounce of water through to wash out the sealant. It would dilute the sealant in the tire a little, but I’m guessing that wouldn’t be an issue water-soluble sealant if it was only done once. Again, I don’t see the need.

The last thing to test was whether or not the valves gathered any sealant or clogged at all after two months of use. Based on deflating and inflating a tire, there was no loss in airflow, but I had to crack open the tire to take a peek. The photo above showed what the valve base looked like after that amount of use. There wasn’t much residue or build-up at all. Impressive.

- Model Tested: Reserve Fillmore tubeless valves

- Fits Rims: 18-28mm Deep

- Tested with: Industry Nine Enduro S Carbon Rims

- Actual Weight: 6 grams per valve

- Place of Manufacture: Taiwan

- Price: $49.95 (pair)

- Manufacturer’s Details: ReserveWheels.com

Pros

- Increased airflow makes seating a tubeless tire easier than ever

- Poppet valve and no clog design are amazing

- Cap-press engaged air bleeding works well

Cons

- Very expensive

- Losing a cap would likely mean contaminants could get inside

- If the O-ring fails, the the main part of seal is toast

Wrap Up

Considering the pace of innovation in the cycling industry, particularly on the mountain bike side of things, I’m honestly surprised it took this long for a company to rethink and retool the Presta valve. It wasn’t something I thought about prior to seeing the Reserve Fillmore valves, but it was a bit of an aha moment once I did. Prior to the Fillmore, Presta valves were just something you had to deal with. They get the job done, but they’re a remnant of past times before tubeless wheels, tires, and modern sealants became commonplace. Fillmore tubeless valves took that to heart, put the word “tubeless” in the product name, and created something that’s far superior for modern tubeless wheels and tires.

In summary, Reserve Fillmore tubeless valves offer an elegant design that doesn’t clog and demystifies seating a tubeless tire with a floor pump. The biggest hurdle is the cost. 50 bucks for a pair of valves is pretty steep, especially when you can get three or four pairs of Presta valves at the same cost. However, here’s the kicker. After using the Fillmore, I don’t think I can go back.

More on tubeless

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.