Industry Nine Hydra Review: Is it Worth the Upgrade?

With 0.52° engagement, the Industry Nine Hydra hub is the fastest pawled hub on the market. But is it worth the upgrade? We’ve been testing one for several months to find out. Find our full review here…

PUBLISHED Jan 21, 2020

Although a few speedy hubs have hit the market in the last couple of years, Asheville, NC-based Industry Nine was one of the first companies to offer a fast-engagement hub nearly a decade ago. Their Torch pawled hub had 120 points of engagement, which translates to 3° at the crank—or pretty damned fast. For reference, a standard hub has around 60 points of engagement. The fastest star ratchet offered on the classic DT350 has 54 teeth, providing an engagement of 6.6° at the crank. Chris King hubs offer 72 points and a Hope hub has 44 (8.2°). Nowadays, that might be considered fairly slow.

For folks who enjoy methodically picking through technical singletrack and climbing slow, bristly ascents, having a quick engagement hub driver is essential, especially once you’ve tried it. It allows you to quickly adjust cadence and ratchet through craggy bits to avoid hanging up your pedals or cranks on rocks and roots. When I first tried I9’s Torch hub back in 2016, my trail riding game was changed. Since then, I’ve been forced to return to slower hubs on demo bikes, which only confirmed the fact that a fast hub is about as important as a dropper post for this style of riding. So, when Industry Nine released the Hydra, I had to see for myself whether the extra speed was worth the upgrade.

To the Point

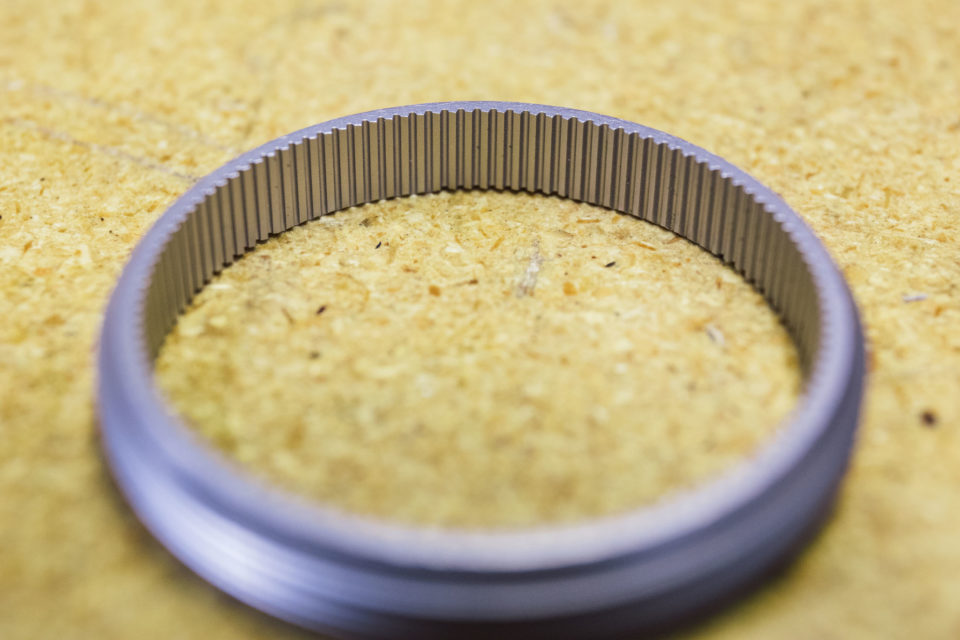

Back in 2013, Industry Nine changed the hub landscape when it introduced Torch. They accomplished that insanely quick 120 points via a hardened steel 60-tooth drive ring designed to work with six pawls that are phased in rotation so only three connect with the drivering at any given time. As mentioned, other companies have followed their lead, too. Boyd Wheels and a couple of other wheel manufacturers matched Torch with 120 points, Project 321’s hubs have a 72-tooth driver that provides 216 points of engagement, and, of course, Onyx uses a sprag clutch to provide immediate engagement. However, Industry Nine answered with Hydra, which took a monstrous leap to 690 points of engagement, or 0.52° at the crank. This removes 2.48° play when compared to Torch, and creates what would seem to be instantaneous engagement. The new Hydra drive system does this by using an independently phased six pawl, 115-tooth drivering.

First Ride(s)

I knew this review would be a long time coming because one of the big questions I had about the Hydra hub is reliability. The other unknown, which was answered much more quickly, was whether or not the faster hub engagement would make me a better rider. Would having a nearly six times faster hub be the magic fairy dust that would allow me to clean tricky bits of trail easier than when I was using the already quick Torch hub? The answer was an emphatic not really. But even though it didn’t make much of an immediate difference to my riding, I was still pretty excited about it. The first thing that hit home about the Hydra was that it simply felt better. It has a higher quality feel and it’s decidedly faster.

The other noticeable difference from Torch hubs is the sound. Industry Nine hubs are known for their high-pitched, bee-like buzz, and some people just don’t like it. I go through phases, loving it on singletrack trails and other times wishing for complete silence. Either way, when I ride a not-so-quick “normal” hub, particularly when trail riding, I greatly miss that fast engagement. In any case, Industry Nine Hydra has a much higher pitched bzzzzzz, so instead of the metallic hornet hive sound of Torch, Hydra has a slightly more pleasant and quieter pitch. For the record, I had Industry Nine pack it with a little extra grease, which made it much quieter. Check out the video (below-left) comparing the two.

For the Sake of Reliability

The big question with any hub is how long it will last and what kind of bearing life should you expect. While we had pretty good luck with Torch hubs, apparently not everyone did, and they certainly had their share of issues. Early bearing wear was a common problem, evidently. This more affected folks who ride hard and put down a lot of power. As such, when Industry Nine set out to design a new hub, faster engagement wasn’t at all top priority. Durability was the pie in the sky. They addressed this with some pretty intense engineering.

Most pawled hubs operate via three or four spring-loaded pawls that engage with the drivering simultaneously. These pawls are positioned to distribute the load evenly around the drivering and apply force equally to rotate the freehub and wheel. However, there are a lot of forces at play when a bike is climbing, cornering, and bouncing down the trail. These forces can play hell with freehub internals. With such hubs, including Torch, this meant that during moments of stress and flex, only one or two pawls might engage, causing an unevenly distributed load on the freehub body and bearings—particularly the drive side hub shell bearing on Torch. The result is increased bearing wear and stunted bearing life.

To solve this, Hydra’s unique design utilizes a continuously phased system, creating a procession of engagement points between pawl and drivering. In simpler terms, that means that as the driver rotates, each of the six pawls engages (clicks into a drivering notch) independently, one at a time–the first pawl, then the second just a split-second later, followed by the third, etc. This allows the drive design to employ the inherent flex of the axle to accomplish positive second, third, or fourth pawl contact, which ultimately avoids overstressing the bearings. Hydra also tempers uncontrolled axle and bearing movements that conventional designs can’t mechanically limit, thus improving bearing life and decreasing resistance. In a nutshell, according to I9, accounting for flex improves bearing life.

To further improve the hub’s durability, Hydra also got a new bearing and axle design. In short, the new configuration uses a smaller diameter axle with a larger bearing. The 15mm axle is about 2mm smaller in diameter than the one on Torch, which was actually a less-is-more kind of situation. The 15mm axle now perfectly fits the thru-axle, making it a stiffer axle system overall. And it also allows for slightly beefier bearings.

Industry Nine Hydra Hub Specs

Hydra Hubs are available in tons of different configurations in 11 different anodized colors. And, they’re configurable in nearly every hub width and axle standard out there. You can also get them with center lock or 6-bolt disc configurations for single-speed and geared transmissions with HG, XD, or Micro Spline drivers. Here are the hub/axle standard details:

Rear Hub Options

For the rear, there are three different hub shell widths with end caps to work with a total of seven different axle standards. All are available with HG, XD, or Micro Spline Drivers.

- DH150/157(SuperBoost) 12 x 150 or 12 x 157 Endcaps

- 148 (Boost) QR141 or Boost 148 Endcaps

- Standard 135/142 QR135, 12 x 135 thru, or 12 x 142 thru

Front Hub Options

For the front, there are two different hub shell widths with end caps to work with a total of seven different axle standards.

- Standard (100mm) QR, 9 x 100, 12 x 100, 15 x 100, 110 Boost conv., 15 x 100 Torque

- Boost (110mm) 15 x 110, 15 x 110 Torque, 120 x 110

Pros

- Extraordinarily quick hub with a better, more quality feel overall

- Quieter than the old Torch hub

- Longer bearing life and more durable design

Cons

- Still not as quiet as Onyx or DT350

- Spokes 28 or 32 Straight Pull (in wheelset) or Classic j-bend (hub-only)

- Colors 11 anodized colors

- Price Wheelsets start at $975 / Hubsets start at $650

- Place of Manufacture Asheville, USA

- Manufacturer’s Details IndustryNine.com

Wrap Up

So to answer the title question of this review: Is Hydra worth the upgrade? My short answer is yes. I’ve been quite impressed with the performance of the hub. Not only is it quieter, it’s noticeably faster. Don’t get me wrong, it’s not going to dramatically improve your technical ratcheting game over the already fast Torch hub. But, it is quicker and generally just feels better.

There’s also evidence to verify the durability question. Around western North Carolina, a lot of people ride I9 Wheels, so local shops know how to service them, and know what issues to expect and how often maintenance is required on them. When I asked folks at the Hub about bearing replacements or other maintenance on the first wave of Hydra hubs, they said they haven’t seen any real issues. Apparently the normal rear bearing life is around 1,000 miles, but a few folks have reported double that. Mine’s showing no signs of bearing wear after nearly 1000 miles.

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.

We're independent

and member-supported.

Join the Bikepacking Collective to make our work possible: