SRAM Eagle Review (GX vs X01): Touring on 1×12

With the gearing needed for loaded bikepacking, SRAM’s 12-speed drivetrains are without a doubt intriguing. And, as more affordable groups and parts emerge, 1×12 is becoming increasingly attractive to bikepackers looking for a modern drivetrain. After 2,500+ miles on the Eagle X01 group and putting the 12-speed Eagle GX drivetrain through its paces in Georgia and Armenia, here’s our full review, complete with a detailed comparison, drawbacks, and a tuning how-to…

PUBLISHED Dec 4, 2018

The internet is already pretty saturated with reviews and tech articles on SRAM’s family of 12-speed Eagle drivetrains. Nonetheless, we thought it would be beneficial to add our own take. And, as with all of our reviews, we’ve put a ton of miles on it and have done our best to make this as thorough as possible. But first, a little background.

In mid-2016—just as 1×11 drivetrains were becoming the new norm—SRAM launched what seemed like the final strike in its war against the front derailleur. However, the $1,100+ price tags on the Eagle XX1 and X01 groups were cost prohibitive to most folks. A year later, as predicted, the tech trickled down and SRAM released Eagle GX, a ~$500 1×12 drivetrain. This year, they went even further, releasing Eagle NX, the budget 12-speed group, and some version of Eagle is now being equipped on the majority of top- and mid-tier 2018 and 2019 mountain bikes.

Touring on 1×12

So, what does all this mean for trail-focused bikepackers and mountain bike tourers? Has the war been won? Is the switch inevitable? The short answer is, no. There are plenty of drivetrain options still available, both used and new; and older drivetrain configurations are still evolving. As explored in our Wide Range 1×11 for Bikepacking Low Down, 11-speed solutions abound. And 2×10 isn’t going anywhere anytime soon, either. What’s more, internally geared systems, such as the Rohloff IGH and Pinion gearbox, continue their evolutionary march. Many bike tourers and long distance bikepackers will brush off the idea of bikepacking on a 1×12 drivetrain altogether, in favor of older standards or the bombproof Rohloff. There are three reasons for this, and each can be at least partially debunked:

1. Parts and Replacements

A lot of folks steer away from modern component ‘standards’ based on the ability to find parts while out on the road—namely chains, tools, and other bits that might be required for replacement or maintenance on a long tour. While there is merit to this (at least for some people and situations), the reality is that there are more people who don’t have the luxury to take multi-month (or multi-year) trips where finding parts on the road is much of an issue. And even so, with a shrinking global world and fast shipping options, it’s not nearly as much of a concern as it once was. Yes, if you are traveling through the remote corners of eastern Africa, nothing short of a square taper bottom bracket and 3×9 drivetrain—or Rohloff—will be failsafe. And even then, things can go wrong. But, with the proper kit and repair knowledge, parts availability should only be a major concern when cycling through places removed from modern bike shops (or reliable places to have things shipped). We recently took Eagle GX on a month-long trip in Armenia, and while we did have one issue, it was generally fine…

2. The Long Range

Until very recently, the biggest hurdle for bikepacking on a 1x drivetrain was gear range, or the lack thereof. The 1×10 and 1×11 drivetrains just couldn’t quite deliver the wide range of their 2×10 and 3×9 forebears. This is especially missed among those of us who frequent the mountains and the steep climbs that they entail, not to mention the necessary granny gear to make up for the extra weight that bikepacking demands. Eagle’s generous low-end granny gear is enough to tempt many riders to 1×12, but others still fear that 1×12 doesn’t match the range of a classic, full drivetrain. This is likely more of a factor for ultra-distance racers or those mixing fast gravel and pavement into their trips. As we argued in our recent wide range 1×11 article, 1×12 – and even 1×11 – has plenty of range for most bikepackers. For the most part, 1x has finally matched the range provided by most 2×10 drivetrains. And this is arguably enough for the vast majority of dirt-focused escapades. Even so, 500% might not be enough range to sway some folks.

3. Chainline and Wear

Another thumbs-down for 1x is the wider chainline variance—having two or three rings at the crank lessens the angle of the chain as it interfaces with the high and low cogs on the cassette. More chainline variability increases cog wear and decreases chain life. As a result, parts may need to be replaced more often, and 1×12 parts are (for the time being) more expensive, especially in the case of Eagle. That said, after putting 1×12 through its paces over the last couple years—including a recent trip on which we racked up 70,000 feet of climbing through the Caucasus—I have been rather impressed by the durability of the Eagle chain and cassette. Unfortunately, there are issues with one of the derailleurs, and we can now see its merits and pitfalls, for both Eagle X01 and Eagle GX. More on that later.

Even after taking these arguments into account, 1×12 Eagle is a completely viable option for many bikepackers—perhaps even more so for those who are trail mountain bikers first and bikepackers second, whose adventures range from weekend exploits to month-long bikepacking rides. If you’re a bike traveler destined for a multi-month, multi-country trip, you might be better off sticking with older standards, depending on the countries you’ll be visiting.

Either way, if Eagle is on your radar, you might be wondering about the differences between Eagle groups, and which one’s more suitable to touring and bikepacking. Or perhaps you’re wondering about the possibility of mixing and matching components for an affordable and durable Eagle group. While we haven’t tried the NX group, we’ve put a lot of miles on the GX and X01 Eagle drivetrains. Here are all the nuts and bolts of the systems compared, followed by our experience with the two groups.

EAGLE GROUPS COMPARED

The SRAM Eagle GX and NX groups possess much of the same tech as Eagle XX1 and X01. This includes the unique tooth profiling and functional/construction advances throughout the system. As one would expect, being on the lower end of the line, there are a few feature differences to cut costs, mainly materials and manufacturing processes, which both increase weight. For the sake of this article, we’ll leave XX1 out of the discussion and focus on the three Eagle groups that are more financially accessible. Here are the differences based on the four main components.

Eagle Cassettes Compared

Aside from the Eagle crankset, the models of Eagle 12-speed cassettes have the most significant disparities in materials, construction, weight, and price. Here are the specs and differences:

NX (PG-1230)

– 11-50t (454% range)

– Shimano 8/9/10-speed driver

– 8 lightweight, stamped steel cogs and 4 high-strength steel cogs pinned onto an aluminum spider

——–

Weight: 615 grams

MSRP: $100

GX (PG-1275)

– 10-50t (500% range)

– XD Driver

– Full-pinned, one-piece stamped steel cogs held together with stainless pins

——–

Weight: 446 grams

MSRP: $215

X01 (PG-1295)

– 10-50t (500% range)

– XD Driver

– One-piece machined steel cluster with alloy 50-tooth cog

——–

Weight: 354 grams

MSRP: $385

Even though both the GX and X0 cassettes are one-piece construction, there is a significant difference in how they are made. The X01 cassette is machined from of a single piece of steel with an alloy 50t ring pressed into the 11-cog cluster. The GX option is made of individual stamped steel rings that are pinned together. Apparently, one other difference is that the X01 cogs have a higher-end coating that helps extend the life of the cassette. We put a ton of miles on both, read on for the results.

Eagle Derailleurs Compared

Generally speaking, each of the Eagle derailleurs functions the same way. They all have the newer X-HORIZON design with a Type-3 ROLLER BEARING CLUTCH, as well as CAGE LOCK to secure the cage while performing maintenance. The real differences between each model are in the materials used. Most importantly, as we learned from experience – and as you’ll read later in the report – the material used in the pulley cage makes a significant difference for potential issues. That said, SRAM claims that the top-of-the-line versions are more precise and potentially more long-lasting due to tighter tolerances and assembly requirements. Here are the main differences:

NX Eagle Rear Derailleur

– Stamped steel pulley cage

– Riveted steel pulley pins

——–

Weight: 339 grams

MSRP: $107

GX Eagle Rear Derailleur

– Stamped steel pulley cage

– Steel pulley pins

– Steel spring

——–

Weight: 288 grams

MSRP: $125

X01 Eagle Rear Derailleur

– Forged alloy pulley cage

– Steel pulley pins

– Titanium spring

——–

Weight: 276 grams

MSRP: $225

NOTE: SRAM has changed the specs on the GX Derailleur on their website; the latest GX has both an alloy front cage and an alloy back, instead of stamped steel.

Eagle Cranksets Compared

As mentioned, the Eagle crankset models vary significantly in both weight and price. While these are part of each SRAM Eagle group, we won’t spend a ton of time on them as they are not absolutely necessary when piecing together a 12-speed drivetrain.

NX Eagle Crankset

– 6000 series forged aluminum arms

– Stamped steel chainring

——–

Weight: 705 grams

MSRP: ~$105

GX Eagle Crankset

– 7000 series forged aluminum arms

– Stamped alloy chainring

——–

Weight: 620 grams

MSRP: ~$120

X01 Eagle Crankset

– Carbon fiber arms

– CNC machined alloy chainrings

——–

Weight: 510 grams

MSRP: ~$400

Eagle Shifters Compared

Although SRAM claim the X01 shifter employs a higher-precision shifting mechanism than the NX or GX, the biggest notable difference in the shifters are the materials used on each. Otherwise, the only difference between GX and X01 is that the latter has an adjustable trigger.

NX Eagle Trigger Shifter

– All plastic construction

– Forged aluminum trigger

——–

Weight: 112 grams

MSRP: $42

GX Eagle Trigger Shifter

– Plastic with alloy bottom

– Forged aluminum trigger

——–

Weight: 122 grams

MSRP: $45

X01 Eagle Trigger Shifter

X01 Eagle Trigger Shifter

– Alloy cover and bottom

– Adjustable alloy trigger

——–

Weight: 124 grams

MSRP: $130

Eagle Chains Compared

The Eagle 12-speed chain design is perhaps the most interesting part of the entire system. In order to add another cassette cog to fit on the company’s existing XD driver, SRAM engineers overhauled the chain design, reducing the outer link width by about 0.35mm from that of an 11-speed chain. Even more interesting, the link plates have a smooth, chamfered edge. SRAM claims this yields a significant reduction in noise, friction, and wear on chainrings and cassette cogs. They also say the higher-end chains work more smoothly, and in turn increase the lifespan of the entire drivetrain.

NX chain

– Steel plates

– Solid steel pins

——–

Weight: 278 grams

MSRP: $26

GX chain

– Steel plates

– Chromed solid steel pins

——–

Weight: 265 grams

MSRP: $33

X01 chain

– Steel plates

– Chromed hollow pins

——–

Weight: 256 grams

MSRP: $60

SRAM Eagle GX vs X01 vs NX

For comparison, at $495, SRAM Eagle GX is less than half the price of the Eagle X01 group ($1,155) and almost a third of the $1,355 price tag of Eagle XX1. In terms of weight, the full SRAM GX group (derailleur, cassette, chain, shifter) shown above weighs in at about 1741g grams. That’s about 230 grams (a half a pound) more than the carbon X01 Eagle group.

One important thing to note about the entry-level NX group is the fact that SRAM nixed the XD driver body for the NX Eagle cassette. Instead, the PG-1230 12-speed cassette mounts on a standard 8/9/10-speed splined Shimano or SRAM driver. This means one fewer expense required to upgrade to 1×12. But, they also made it 11-50t instead of the wider 10-50 found on the GX and X01 versions. And, of course, the biggest draw with Eagle NX 1×12 is the price of the full drivetrain.

All told, the $380, 2,049 gram SRAM Eagle NX 1×12 drivetrain is about $120 cheaper and weighs 299 grams more than the full GX Eagle (excluding XD Driver), which comes in at 1,741 grams for about $500.

EAGLE GX vs X01 (TESTED)

Installation and Setup

Installation is the same as any drivetrain, with the exception that it requires an XD hub driver and cassette lockring remover tool. Otherwise, installation of both drivetrains was fairly straightforward and they were easy to tune. However, there were issues that arose with the GX drivetrain on the first day of riding. Let me first admit how terrible I am (was) at properly tuning a drivetrain. Years on a Rohloff and several mechanic friends have made me soft. On the first day of our trip in Georgia, I almost threw the bike over a cliff wrestling with the GX derailleur. We later realized the issue was a bent derailleur hanger that probably got kinked during the flight over. That said, even after straightening the hanger, I still couldn’t get it to shift into the 10T cog. This was not only due to me completely ignoring up the B-Gap. So, before I go on…

How to Tune an Eagle Derailleur

Even after getting the Eagle GX derailleur running well enough, the higher gears were never perfect; I had to tune the derailleur several more times throughout the trip and could never quite get it perfect. Upon returning, I got schooled by local mechanic, TJ Kearns. TJ gave me a step by step how-to on properly tuning an Eagle GX derailleur. We also found an issue with mine. Here’s a quick tuning guide:

- 1. Set your limits. The first step, even before you clamp down the cable, is to set the limits. Do this by using your hand to force the derailleur and chain up to the 50t cog and down to the 10t. First, you can eyeball it. Then, get sloppy and aggressive with it, and slam it into the high and low gears until you get it where it won’t fall off into the spokes, and just enough on the high end where it feels right.

- 2. Secondly, set the barrel tension on the shifter. Screw in the barrel tension adjustment screw on the shifter (righty-tighty) all the way. Then, back off three clicks to the left.

- 3.Pull the cable gently and clamp it down. For Eagle GX, we found the cable had to remain rather loose.

- 4. Set the B-tension (aka B-Gap), the distance between the upper pulley and the cassette. Setting the B-tension is key to achieving optimal shifting performance. SRAM provides a small plastic gauge (here’s their how-to video) with the rear derailleur. You can find plenty of detailed videos on YouTube to learn how to use it. Note that B-tension affects the cable tension.

- 5. Fine tune the shifter tension with the barrel tension screw.

General Toughness

Despite meticulously tuning the Eagle GX derailleur, there was still one issue that TJ discovered in the process. The derailleur cage was a little bent. It was almost unnoticeable, but enough to cause it to shift improperly. Before we discovered this, we had to over-tension the limit screw in order to keep it from falling off the 50t cog, which had the unwanted side effect of preventing it from dropping into the 10t cog.

Herein lies the problem with the Eagle GX rear derailleur. TJ sees bent GX derailleurs come into the shop where he works on a regular basis. The stamped steel cages SRAM specced on them are “a little soft,” according to TJ. Apparently, unless you work with these day in and day out, it’s rather hard to discern. Fortunately, they don’t break that often, and if you know a little bit about how to “massage” them back into shape, you should be able to rectify this situation in the field, should it arise. Otherwise, I have no major complaints with the shifter or cassette. So after a proper application of gentle cage bending, it’s finally back in perfect shifting order.

I’m happy to relay a much better report for the Eagle X01 group. After two years and a conservatively estimated 2,500 miles of use, both on the rugged trails of Pisgah as well as plenty of bikepacking outings, it has needed tuning a total of zero times and has always worked without issue. According to TJ, the X01 derailleur has a much better build quality, is more resilient to knocks, and generally superior to its GX sibling. Part of this is owed to the stiffer forged alloy cage, but there may be something to be said for the upgraded construction as well.

Shifting and Performance

Considering the price gap between the Eagle GX group and its X01 sibling, it shifts pretty well and feels more solid and precise than I would have expected. However, it seems to lack the clean, crisp, precision feel of the full X01 group, which is by far the nicest SRAM drivetrain I have used to date.

As mentioned, after thousands of miles, the X01 group still shifts buttery smooth. Significantly smoother than Eagle GX, in my opinion. I believe this is due to a lot of subtle differences in materials and manufacturing processes in the cassette, shifter, and derailleur. That said, the derailleur is the most important upgrade of the two groups, based on durability alone. The one-piece machined steel construction of the X01 cassette is also quite nice, and probably plays a significant role in the X01’s crisp shifting. But, I also don’t think it’s worth paying $170 more than the GX full-pinned steel model.

Gearing

As mentioned, 95% of trail mountain bikers, bikepackers, and even bike tourers would be happy with the 500% range offered by 12-speed Eagle drivetrains. With a 30t ring up front, the GX drivetrain was perfectly geared for the steep Caucasus Mountains in Armenia and Georgia. Note that that was on a bike with 29 x 2.6” tires, so the 30t ring was a godsend for the steeps. This gearing, with the 2.6” tires, translated to about 17.8 gear inches in the lowest gear.

The X01 system was set up on the Salsa Pony Rustler with 27.5 x 3” tires. With a 32t chainring, there was plenty of low gear for lightweight bikepacking—the lowest being about 18.6 gear inches. Both setups have plenty of high gearing as well. The small 10t ring on the GX and X01 cassettes provides appropriate higher gears for a loaded trail or dirt road bikepacking rig as well. The GX/30t bike had a high gear of about 89 gear inches with 29 x 2.6” tires, and the X01 bike had 92.8 gear inches with the 32t ring and 27.5 x 3” tires. For most people (other than some racers), this is plenty of gear range for both loaded and unloaded mountain biking.

While the range of gearing can now be matched by 11-speed cassette expanders, 12-cassette cogs provide a slightly smoother shifting range with less dramatic steps. This is one of the biggest advantages to a 12-speed drivetrain when comparing it to wide range 1×11 or 1×10.

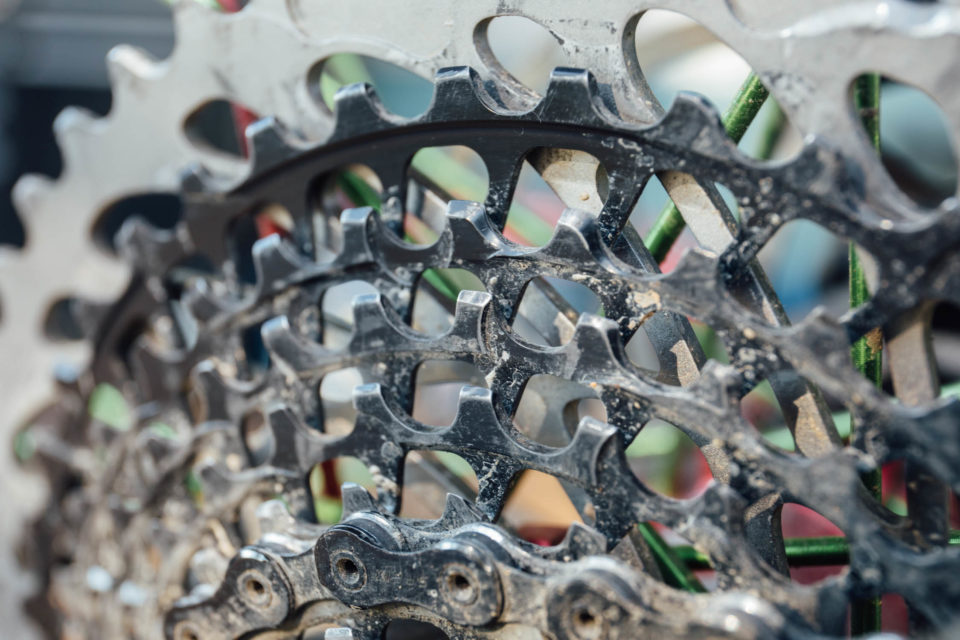

Wear

As far as overall wear, I will focus on the chain, chainring, and cassette. Ultimately, I am extremely impressed at how well each of these components have held up on both the Eagle GX and X01 groups. Surprisingly, neither chain yet needs replacement, both showing less than .75mm of chain stretch on a standard chain gauge. This is especially impressive with the high mileage on the X01. Both chainrings are also still in great shape, with neither needing replacement (see photo below).

The cassettes are both in amazing condition, considering the mileage. The three photos directly above show the X01 (PG-1295) which I was quite shocked to find in excellent shape, showing very little wear after 2,500= miles. The GX looks a little more worn after half the miles, but keep in mind that there were some tuning issues which may have caused a little premature wear. All that said, I sincerely think that both of these drivetrains are far superior in durability than any 1×11, 1×10, or even 2×10 system I have used.

Mix and Match: Questions Answered

Unless you work with these components on a regular basis, all this information often leads to a lot more questions, especially when it comes to picking and mixing the best parts from the different lines to save money and increase the lifespan of the drivetrain. We decided to put our findings in a question and answer format for clarity:

Can you use an 11-speed chainring with a 12-speed chain/cassette?

Yes. The chain pitch (distance between the chain’s roller pins, center to center) on 10-, 11-, and 12-speed chains is the same—approximately 1/2″. And, the inner width from plate to plate is also the same at 3/32” (2.38mm). What changes from 10- to 11-speed, and from 11- to 12-speed, is the outer width of the chain. This od the result of thicker plates. An Eagle chain is approximately 0.35mm narrower than an 11-speed chain. This change was necessary to allow one more cassette cog to fit on a cluster and mount on the same XD hub driver on which SRAM’s 11-speed drivetrains also mount.

Will using an 11-speed chainring affect the performance of a 12-speed drivetrain?

Yes, and no. One of the major technical advancements of Eagle is in the chainrings, specifically the tooth profile design. The radical shark tooth profile was engineered to lessen chain and tooth wear, and to increase chain retention. Not only are these chainrings are extremely smooth and quiet, they seem to contribute to less chain wear. I have been extremely impressed with the lack of wear on both of the chainrings we’ve tested. In addition, and even more surprising, both chains are still in great shape. Even with over 2,500 miles on the X01 chain, it is still showing almost zero roller and rivet wear (aka stretching).

Can you use an 11-speed chain on a 12-speed cassette?

No. there is no backwards compatibility with cassettes—an 11-speed chain is too wide (outer width) for a 12-speed Eagle cassette. The cog spacing is approximately 3.8mm on 11-speed cassettes and 3.65mm on Eagle cassettes.

Are there reliable third-party parts available for 12-speed?

Yes. There are a few options for chains these days, KMC and SunRace being the two most accessible. However, they’re not much cheaper than the $26-33 SRAM PC-GX chain (you might save $5-8, but these options are untested by us). As far as cassettes, Sunrace offers a 12-speed cassette (CSMZ80) with an MSRP of $88. That’s a significant savings over the $215 GX cassette, but the Sunrace is not a full-pinned, one-piece cassette. Instead, it uses an alloy spider to carry two separate cog clusters and five individual cogs with two spacers.

What’s the best mix and match solution to get a relatively inexpensive and reliable Eagle group?

Although Eagle X01 is awfully nice and shifts extremely well, it’s a big investment. In my opinion, most people starting from scratch would be better served by combining a GX cassette (PG-1175) with an X01 derailleur, a GX shifter, and a GX chain. This would get you in the door with a very reliable system for between $500-520. From there, use a standard direct mount crankset and an 11-speed chainring, or, ideally, the Wolf Tooth Camo system to make swapping rings cheaper and easier (plus, they offer a stainless narrow/wide ring).

Eagle 1×12 Pros

- Excellent shifting performance. I used to be a Shimano-only person, but I have been extremely impressed with the performance and smooth shifting that Eagle offers, especially the full X01 group.

- 12-speed offers the ideal range for most trail riding and bikepacking excursions.

- Smoother shifting than 11-speed. While this can now be matched by 11-speed cassette expanders, 12-cassette cogs provide a slightly smoother shifting range with less dramatic steps.

- Clean cockpit. As with 1×11, many people appreciate 1x drivetrains for the ability to have fewer cables and components—one less shifter, one less cable, and one less derailleur.

- The full-pinned GX cassette is a pretty good value.

- The latest tech for extending chainring and chain life (as far as 1x goes). The condition of the X01 system after 2,500+ miles is very impressive.

Cons

While there are many pros to an Eagle 12-speed drivetrain for bikepackers, there are several cons you should consider if you’re on the fence about 1×12:

- Standards. Both the PG-1175 (GX) and PG-1195 (X01) cassettes require an XD driver. This restricts many older hubs from being used.

- Eagle replacement parts aren’t cheap. The GX cassette, while full-pinned steel and very robust, will eventually wear out. And, when it does, that’s a $215+ replacement part.

- Not many third-party alternatives. This will likely change fast, but right now, there aren’t too many options for cassettes and chains.

- Eagle rear derailleurs have a long cage to handle a longer chain. This means there’s more derailleur dangling out there to get snagged, bumped, bent, and possibly broken. This is a concern when riding in areas with a lot of sticks or vegetation, as well as when transporting the bike.

- Parts might be difficult to find in some places, and impossible to find in many developing countries.

There was a lot said here… about 4,500 words worth. So, we’ll leave it at that. However, if anyone else has any experience with touring on a 1×12 drivetrain, issues with any of the Eagle drivetrains, or big-mileage successes to report, please leave a comment below.

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.