Tectonic Components Altar Pedal Review

Released earlier this year, Tectonic Components’ flagship product, the Altar Pedal, is a premium US-made platform pedal with easily serviceable internals, grippy traction pins, and a carbon-reinforced nylon body. Find our thoughts after a few months of regular use here, plus an interview with the makers and some additional insight from Alexandera Houchin…

PUBLISHED Sep 14, 2022

Owned and operated by Andrew McKee, Tectonic Components is a new parts manufacturer that launched its flagship product earlier this year, the Altar Pedal. The pedal is based on several years of testing and prototyping, and it was born out of Andrew’s lifelong obsession with bikes. What started as a mission to design better traction pins eventually evolved into the creation of a performance platform pedal that’s easily serviceable, extremely durable, and impressively lightweight.

My friend Marc Basiliere over at Lindarets—the one behind the original high-flow titanium valve stems—first introduced me to Andrew and his small company. Not only do Marc’s belts share a similar carbon-reinforced construction to the Altar Pedals, but both makers clearly have an obsession with thoughtful product design, so I took Marc’s recommendation seriously. Over the last few months, I’ve tested the Altar Pedals on local laps here on the BC coast, several overnighters and weekend-long campouts, and some demanding high-alpine singletrack riding outside of Lake Chelan, Washington. For one reason or another, I’ve also had a record-high number of pedal strikes and hike-a-bike this fall—smashing the pedals off rocks, roots, and stumps that had me wincing every time. Keep reading for my thoughts on how they’ve performed, a brief interview with Andrew, and some feedback from fan-favorite bikepacker Alexandera Houchin after more than 1,000 miles of solid use.

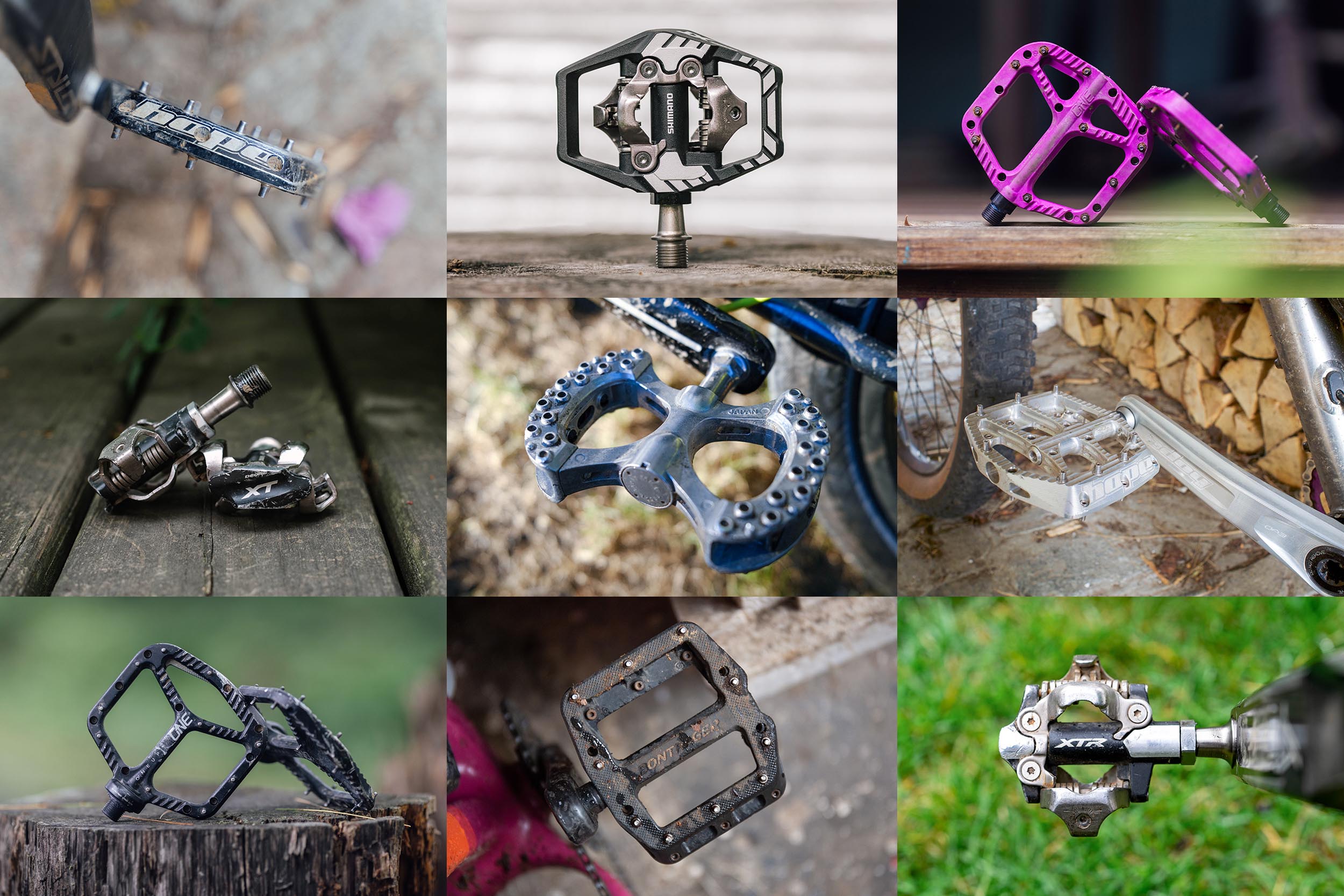

The Altar Pedals come shipped in a recyclable cardboard box without any unnecessary plastic. The platform is 110mm wide x 120mm long, with a 2mm concavity tapering in towards the axle. They are 15mm thick at the centre of the platform and weigh just 330g/pair. To offer a comparison, the OneUp composite pedals weigh 355g, Bontrager’s composites weigh 355g, and most aluminum pedals weigh closer to 400g. They are impressively lightweight and almost felt too light when I first unboxed them. A combination of a minimalist design and their construction has allowed Tectonic to achieve this, and the result is hard to believe.

The body of the pedals is made from carbon fiber reinforced nylon, a thermoplastic “that exceeds the strength of aluminum while also being more inclined to glide over rocks, rather than sticking or catching.” They feel extremely dense considering their weight, especially when compared to standard composite pedals, and the exterior surface is smooth and solid, save a few weight-saving indentations on the edges. Pedal blanks are injection molded in Michigan and then machined into their final form in Durango, Colorado.

Grip is provided from 10 patent-pending hardened Hitachi stainless steel pins that are fixed into position using a side-loaded bolt. This allows for easier removal when it comes time to replace, and because the body itself isn’t threaded, any pin can be removed, no matter its condition. Since one pin provides grip on both sides of the pedal, they should be easy to remove even if they are truly mangled. There are four cartridge bearings per pedal that spin on a heat-treated stainless steel spindle and can be easily serviced with standard tools.

On the shoes I’ve tested the pedals with, which include the Specialized Rime Flats, Ride Concepts Tallac, and my Bedrock sandals, the Altar Pedals grip hard but don’t make it impossible to unweight my foot to adjust my position. While bouncing down Angel’s Staircase in Washington, a chunky singletrack loop northwest of Chelan, I was always confident my feet would stay put but never had to peel them off to tweak things. The concave platform made it easy to discern my foot’s position on the pedal at all times, especially on the thinner soles of my Bedrocks, often allowing me to change my foot position without glancing down. The generously sized platform also assists in traction and feel. In fact, at 110 x 120mm, I couldn’t find comparably sized pedals other than the hilariously large Pedalling Innovation Catalyst pedals at 95 x 143mm.

The carbon fiber reinforced nylon constructed has also proven to be durable, shedding off pedal strikes and glancing off rocks and roots with ease. I’ve been impressed at just how nice the pedals still look, considering what I’ve put them through, which is partly why I’ve never been a huge fan of anodized metal pedals. There’s a raw, homegrown aesthetic to the Altars that I can’t see diminishing with age.

Interview with Andrew McKee

Can you tell us a bit about Tectonic Components and the people behind it?

Tectonic Components is a one-man show that I run out of my garage here in Durango, Colorado. I’m a full-time bike mechanic, so this is still just a passion project for the time being. I’ve been living in Colorado since I graduated college, and, at the risk of sounding cliche, my whole life revolves around riding bikes. Working in a busy shop in a bike town like Durango helps with insight into what works and what doesn’t. The mission for Tectonic is to make innovative and high-quality components here in Colorado to address real-world demands we find on the trails, and to make products that last and have parts available to keep them on the trails.

Why make a premium platform pedal? Aren’t there enough options out there already?

There are a lot of different approaches to a premium-level platform pedal, and there are some great options out there, but I feel that none of them get everything right. I wanted to hit on all of the details that matter most (concavity, platform size, bearings, pin design), while making the product itself locally. I’m pretty darn proud that I was able to pull that off while still fitting in the same price tier as the competition. After testing prototypes and benchmarking against the best of the rest, I realized that this design offered tangible performance benefits, which was the goal. I didn’t want to bring a product to market that was the same as what was already available.

What influenced the design of the Altar Pedals?

Once upon a time, I spent a summer riding as many of Colorado’s 14,000-foot peaks as were legally available to ride. I wound up dragging or plowing my bike into countless rocks on awkward sections of the trail. Several pairs of pedals were sacrificed on those peaks, as I couldn’t replace the mangled pins, or the bushings would start to wear, and in turn the spindle, so even a fresh rebuild never got them feeling like new again. This project started as an exercise to design and test a better traction pin design; to have a pedal that offered longevity and was less of a disposable, one-season item.

Why carbon fiber-filled nylon? What even is that?

I was enamored with some of the properties of nylon pedals, despite the low-performance design on most examples, so I looked into the strongest varieties of molded nylon parts. Carbon-filled nylon is your standard PA66 nylon, but filled to 40% with long fiber carbon fiber. These long fibers (as opposed to short fibers, which are more common) create a reinforcing matrix in the part, resulting in greater strength than aluminum at a lighter weight. This material is marketed as a metal-replacement technology, and with proper mold design, can make for an incredibly tough and resilient part.

Tell us more about the manufacturing process.

We have our pedal body blanks injection molded at a facility in Michigan. These come out with lots of extra material in place as the mold is designed around flow simulations to make sure there are no “weld lines” where uneven flow would prevent a strong fiber orientation, so these molded parts are then machined here in Durango, Colorado, to their final form. We also machine and heat-treat our spindles in the same machine shop. Finally, the pedals are all hand assembled and packaged in my garage.

How does one know when to service their pedals?

Most riders should get a full season or more from the internals, but we tried to make it as easy as possible to refresh the chassis and get them feeling like new. As the bearings wear, it may be necessary to adjust the preload, but like all bearings, they will eventually wear out. This is a similar thought process to servicing a hub; replace the bearings when they feel rough, notchy, or have excessive play. We do have extra seals at both sides of the pedal to keep water out, but riding in wet conditions will generally make service intervals closer together.

What’s next for Tectonic Components?

In the short term, I want to continue to grow and build momentum with the Altars, and then to parlay that into building more high-quality components here in Durango. I have plans to build a version of the Altar with a smaller footprint for kids and those with smaller feet, as well as a line of clipless pedals using the same cartridge bearing internals. This has been a challenging but very rewarding process, and hopefully the experience will allow Tectonic to grow and produce components that riders will appreciate and can trust.

Alexandera Houchin’s 1,200-mile Mini-Review

Words by Alexandera Houchin; portrait by Jennaye Derge (@jennaye_d)

Tectonic Pedals are the shit!

I’ve broken way too many pedals to trust any ol’ pedal these days. My Race Face Chesters snapped off at the axle during the 2019 Unbound XL, my Race Face Atlas stripped off the axle just outside of Butte, Montana, during the 2019 Tour Divide, a OneUp Alloy pedal seized up on me on my 2021 AZT300 XL attempt, and most recently, I pulled a TMAC Diety off the spindle on a short tour. I replace my pedals just before every race I do nowadays and still had anxiety around my pedals before I found these. I even went as far as bringing a pedal rebuild kit and the tools for Unbound XL 20222. I have a few disclaimers though: I weigh 200 pounds, I ride a singlespeed, I have a solid deadlift, and I ride the pedals hard and continuously for ultra-races. All that to say, I put so much power into those pedals.

When I heard about Tectonic pedals, I reached out to Andrew with an email introducing myself and asking him if we could start a bike sponsorship relationship. I asked him if he would be interested in sponsoring me for my 2022 Colorado Trail Race by telling him I was defending my two-win title. He explained he was a small company and didn’t have the capacity to give me free pedals, but he would help me out by selling them to me at cost. I agreed right away. I try to be as intentional as I can when choosing brands and companies to work with, and I’d rather pay for good stuff and to support an artisan than just take free shitty stuff. I also prefer to support MUSA companies when I can.

I WAS STOKED on the pedals. I’ve been hunting for good, tough pedals, and a company I could have a relationship with—like a real human who could help me make sure my pedals don’t explode every time I’m doing a massive effort.

The pedals: Super buttery bearings, a massive platform that helps with foot fatigue, the carbon pedal is super light, and sticks really well to my shoe. I’m not wearing cycling-specific shoes, so finding a good pedal/shoe combination is always a treat. Tectonic offers bearing rebuild kits and traction pin kits, which are super affordable and so much easier/smaller/more compact than any other brand I’ve seen. My only criticism was with my toe would occasionally get caught in the space of the platform when going from standing to lifting my foot onto the pedal early on, but once I got used to the pedals, it never happened again.

They’re probably the biggest platform I’ve seen on a pedal and that made for super confident descending. Further, I love lifting (as in heavy lifting) and it felt like a better transfer of my power while climbing. I could really press when climbing, and I couldn’t be more happy with the pedals. I like them so much that I also purchased a pair for my partner, who has really big feet. Andrew reached out after the race to ask how the pedals were, and I’m getting new bearings pressed into the pair I raced for the CTR.

Disassembly and Service

Although I haven’t needed to service the pedals and they’re spinning as smooth as they did on day one, I figured it was worth removing them to take a peek inside. Replacing the sealed cartridge bearings and greasing the internals is a straightforward process, requiring no speciality tools to get the job done. It’s nice knowing that you’ll be able to service your pedals rolling into nearly any town should the situation arise.

Disassembly requires 6mm and 8mm hex keys and a 1/4″ drive 8mm deep socket. The end cap is removed with a 6mm hex, allowing you to clean the cap and replace the O-ring if necessary. With the 8mm hex key holding the inboard side of the spine, the 8mm socket removes the exposed locknut, thereby allowing the spindle to be removed from the pedal body. The spindle also has a replaceable O-ring than can be swapped out if needed. There are three outboard bearings and a larger inboard bearing that can all be tapped out using a hex key and replaced as needed. When putting the pedal back together, the spindle serves as a guide pin and press when seating the bearings back into the pedal body. Reverse the steps above, set the preload using the locknut until there is no side-to-side play, and you’re done. When it comes time to replace the traction pins, they are removed using a 2.5mm hex key, replaced, and tightened back into place. The only downside here is that their patent-pending pins are proprietary, so you won’t have any luck finding them anywhere but through Tectonic.

Pros

- Large concave platform assists with feel, stability, and power

- Made in USA

- Durable and lightweight

- Serviceable internals and traction pins

- Alexandera Houchin-approved

Cons

- Expensive

- Platform might be too big for those will small feet

- Proprietary traction pins

- Most folks won’t carry an 8mm deep socket on the trail

- Material: Carbon fiber-reinforced nylon / stainless steel spindle / alloy cap

- Weight: 330 grams/pair

- Place of Manufacture: Michigan / Colorado, USA

- Price: $199 USD

- Manufacturer’s Details: Tectonic.Bike

Wrap Up

There’s no question that the Tectonic Altar Pedals are expensive and out of reach for most people, especially considering you can grab a solid composite pedal for under $50. However, for those of us heading far away from cellular coverage and looking for the best in reliability and US-made quality, they’re worth considering. From the easily serviceable internals to the side-loaded traction pins, the Altar Pedal is clearly designed for the long haul and meant to be serviced and cleaned for years.

When it comes to bikepacking, the oversized platform provides lots of support in any type of footwear, it’s grippy enough without feeling too sticky, and if they’ve held up to Alexandera Houchin’s pursuits, I’d say they’ll be more than durable enough for us average folk. If any of that is important to you and you’re interested in supporting a small start-up business, the Altar Pedal could be one of the last pedals you ever buy.

Related Content

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.