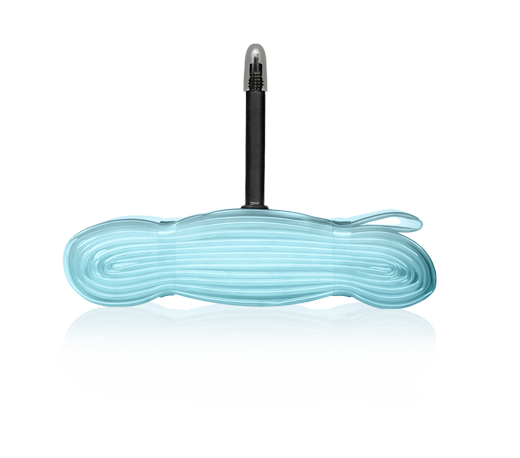

The new Schwalbe Aerothan Tubes are a high-end, lightweight alternative to conventional bicycle tubes—plus they are 100% recyclable. Find the product launch video and an interview with one of Schwalbe’s product managers here…

The Schwalbe Aerothan Tubes are the latest lightweight, packable alternative to conventional rubber bicycle tubes. They claim they are 40% less weight than a comparable rubber tube, have great puncture protection, minimal rolling resistance, and are extremely heat resistant (rated for rim brake use). The Aerothan Tubes are made from thermoplastic polyurethane (TPU), including the valve, and are therefore completely recyclable. Like all Schwalbe tubes, Aerothan tubes may be returned to Schwalbe at no cost using their tube recycling program. The material of used tubes is recycled to make sealing or insulation material. The tubes come in 26″, 27.5″, 29″ and 700c sizes, in a few different widths, and weigh between 41g and 116g.

Check out the product launch video below, followed by a Q&A with Schwalbe Product Manager, Felix Schäfermeier, originally posted on Schwalbe’s website.

Schwalbe Aerothan Tubes

| Product | Wheel Size | Tube Size | Weight | Price |

|---|---|---|---|---|

| 26″ MTB | 26″ | 54/62-559 | 81g | €27.90 |

| 27.5″ MTB | 27.5″ | 54/62-584 | 83g | €27.90 |

| 27.5″ MTB+ | 27.5″ | 62/75-584 | 109g | €27.90 |

| 700c Race | 700c | 23/28-622 | 41g | €27.90 |

| 700c Race Endurance | 700c | 28/35-622 | 50g | €29.90 |

| 700c Allround | 700c | 37/50-622 | 61g | €27.90 |

| 29″ MTB | 29″ | 54/62-622 | 87g | €27.90 |

| 29″ MTB+ | 29″ | 54/62-622 | 116g | €29.90 |

How did you come up with the idea of developing a bicycle tube without rubber?

Bicycle tubes are a huge challenge for developers because one needs to combine completely opposing features in one product. A tube must be light-weight, but also extremely stable. With a classic butyl tube, one can achieve great puncture protection and excellent air holding capacities, but realising low weight is the limiting factor. Exactly this is why we wanted to completely rethink tubes and have decided to search for alternative materials. In cooperation with BASF, we have developed a thermoplastic polyurethane (TPU), which suits extreme requirements: Aerothan.

What was the biggest challenge during developments?

TPU-plastics already have many different applications in industry, e.g. as sealing or insulation material. And the approach to use this material for tubes is not new. However, past attempts have had significant limitations. For example, tubes were not approved for use with rim brakes due to a lack of sufficient heat resistance. We wanted to change this and have come up with special testing procedures to be able to test various materials. A thermoplastic polyurethane has allowed us to create an entirely new material base.

Is Aerothan a completely new material?

Yes, absolutely! In cooperation with BASF, we were able to reinvent Aerothan from scratch. Not only did we redevelop the base material, but we also redesigned the entire manufacturing process. During this phase, we got to benefit enormously from the expertise of German companies within the plastics processing industry. Aerothan tubes are produced in Germany using a patented laser welding process. This particular technique allows high precision welding of the valve and tube. In addition, it allows production of extremely flat seams that, not only secure a perfect form fit with the tire carcass resulting in extremely smooth riding, but also play an important role for puncture protection. After all, seams are subject to extreme mechanical stress. The durability of the seam was proven in several tests.

How was this tested?

Aerothan was subject to various lab and field tests where it was compared to existing materials and systems. An important point on the specifications sheet was also thermal resistance when used with rim brakes. Here, we have developed a specific test design which simulates high speed downhill rides on mountain descents. Aerothan has achieved an absolutely unique feature and is more heat resistant than all comparable materials.

What about real applications? Can you already tell us who is riding the new tubes?

Aerothan tubes have already been tried out by riders from our Schwalbe athletics programme at various events over the past year. These include MTB races such as Cape Epic, the Enduro World Series and long distance triathlons. The former Ironman World Champion Patrick Lange is very excited to use Aerothan tubes. This does not mean that Aerothan tubes are only intended for competitive athletes. We have also received very positive feedback from cyclists riding around the globe and bike packers. These tubes are just perfect for travelling by bike, because they are super light and stable, yet they do not take up very much space in the luggage.

And what is the verdict about the riding feel?

Aerothan tubes have been tested especially by riders with high tubeless affinity. At first, they were very sceptical, but the overall feedback was positive, some of them were actually surprised about how well the tube performed. Therefore, riding characteristics of Aerothan tubes are on par with the reference – tubeless – when it comes to performance. Normal cyclists also detected an obvious difference to conventional systems. Not only measured test results, but also subjective and individual opinions about the feel are convincing.

Are Aerothan tubes also puncture resistant despite the low weight?

Aerothan tubes are actually much more robust and durable than butyl, latex and other synthetic tubes. During developments, we wanted to focus not only on how Aerothan tubes would resist wear and tear when cycling, but also how the material would respond in the worst case scenario. In case of Aerothan tubes, air does not suddenly escape following a puncture, but slowly. If the carcass is cut, the tube will maintain its shape and does not push itself out. For all these reasons, it is much easier to control the bike in case of a puncture and cyclists do not have to worry about sudden air loss.

New materials, especially plastics, raise the question about sustainability. Is Aerothan recyclable?

An Aerothan tube is 100% recyclable – this was very important to us right from the beginning. Just like all other Schwalbe tubes, Aerothan tubes may be returned to us via the tube recycling programme. As opposed to conventional butyl tubes, Aerothan tubes are completely made of TPU – including the valve. This simplifies the recycling process even further. Reusing Aerothan as bicycle tubes is not possible yet; instead, the recycled tubes enter a second life cycle as sealing or insulation material.

Learn more at Schwalbe.com and head to your local Schwalbe dealer to get your own. And stay tuned as we’re hoping to get some of these in for a first look.

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.