Industry Nine: Local Metal.

Conceived in the rhododendron tunnels of Pisgah, Industry Nine’s Torch hubs are touted as having the fastest pawl engagement and the best strength to weight ratio in the business, while their wheelbuilds are second to none. Given that they’re just around the corner, we paid them a visit to find out what makes them tick …

PUBLISHED Jan 4, 2017

When Clint Spiegel started Industry Nine — auspiciously the ninth venture he either partnered in or started — he was no stranger to the machining business. Clint followed in his father’s footsteps, who in 1969 started his first machine shop right here in Asheville, NC. Fast forward 40 years, and when Clint wasn’t manning the family business, he was off pedaling in nearby Pisgah National Forest. Somewhere amongst those greasy roots and dark rhododendron tunnels he realized he could combine his two passions. Wheels — more specifically the hubs — were the most logical place to start.

Nowadays, Industry Nine has made quite a name for itself. With 70+ employees, I9 manufactures 15,000 of their Torch hubs per year and builds 6,000 wheel sets, all designed, tested, and manufactured right here in the southern Appalachian mountains. And more recently, they’ve been toying with several new products including the Matchstix thru-axle toolkit.There’s a lot to be said about high quality products that are handmade in the USA. These days, most metal components in the bike industry are conceived in the US or Europe, and financially squeezed by globalization they’re then machined and assembled in Taiwan or China. And that simple model doesn’t even take into account the procession of materials shipped to and from the manufacturing facility, which may even involve hunks of aluminum taking multiple oceanic barge voyages. It’s refreshing to find companies that do it the old-fashiond way and design, innovate, test, and manufacture the majority of their products in one place. It’s even more special when that place is your home turf and your local trails helped spur the vision behind the products.

War machines.

Marketing honcho, Chris Reichel outfitted us with safety glasses and led the grand tour of the shop, an industrial maze of palatial rooms and impending iron machines that looked as if they were built to equip some quasi-steampunk World War. To him seeing the production was an everyday affair, but I was mesmerized. I suppose the smell of non-ferrous metal and grease can do that to a person. Somewhere along the line Chris mentioned that a couple of the saws being used date back to the Word War II era.

Chris took us through how an Industry Nine hub is made. One of the most fascinating parts of the process is the beginning. Each Torch Hub begins its life as a ‘blank’, a short beer can size chunk of 7075 aluminum, sawed from massive bars of the stuff. Each blank bored on a turning mill to cut the general shape of the hub. Several machines and additional CNC milling operations later, features such as the spoke and disc mounts are carved out and the piece of metal starts to resemble a hub. During the entire milling process, around 90% of the original material is machined away from the blank. Depending on the hub type and size a blank might start at about 900 grams and finish at around 80.

Where the Magic happens.

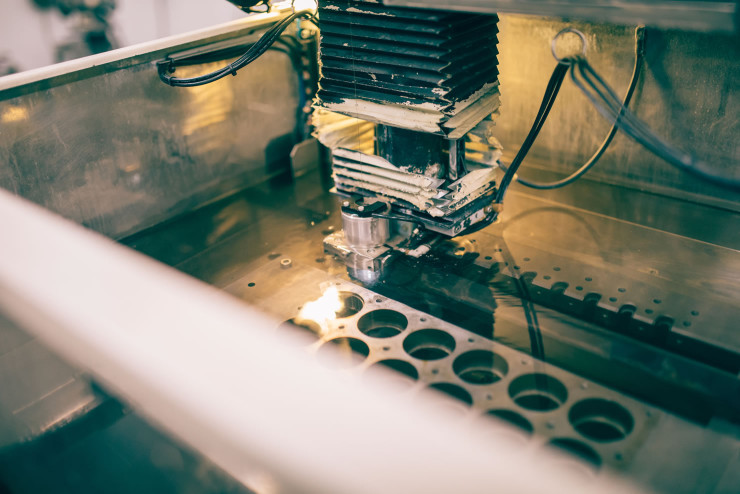

Clint met us at the heart of the operation where the important bits are fabricated that literally make these hubs tick. In a process that’s unique to I9, the steel driver rings are cut from pre-hardened A2 steel using EDM (Electronic Discharge Machining). The EDM machine continually feeds electrified copper wire, barely thicker than a strand of hair, cutting the notches in hardened steel rings. The process takes longer than that behind conventional driver rings — about one every half hour — but the resulting part is far more durable. The pawls are cut the same way. These two parts are what makes I9 both unique and durable. I9 Torch hubs use a six pawl design with 120 points of engagement. As the hub turns the pawls are phased so only three are touching the drive ring at any given time. This results in a nearly instant engagement, three degrees at the crank. For the folks who churn through the technical bits in Pisgah, having a good ratcheting hub is pure gold.

Like watching paint dry.

After the EDM we took a short walk to a long spoke machine. While conventional bike wheels use thin steel spokes, Industry Nine wheels are visibly quite different. They are built using thick one piece aluminum spokes, which I9 claims they are just as strong, if not stronger, and make for an overall stiffer wheel. Like the drivers and pawls, making these spokes isn’t a speedy process. By comparison, a standard steel spoke can be made in a couple of seconds, each Industry Nine aluminum spoke takes about 1.5 minutes, depending on the length. The spoke milling machines are loaded with long rods of raw 7075-T6 aluminum and automatically churn out about 1,600 spokes per day. Watching the spoke machine was about as exciting as watching grass grow… kind of similar too. The end result is a small work of art though.

Rainbow is the new black.

The machined spokes and hubs are then polished and head for the AnoLab, the newest and most futuristic wing of the I9 multiplex. The lab was revamped just several months ago in preparation for the release of their online wheel designer, also called AnoLab. Not to besmirch its importance — after all it’s responsible for the rainbow of color options — the lab is not much more that a series of steaming and bubbling baths and shiny stainless steel wash stations. But the results bring the metal to life. Industry Nine offers 10 different colors for both spokes, hubs, and even the valve stems. Everything from black to pink, and LimeGreen to purple.

For the hubs, there’s two more stops after the anodization. Due to the absolute mathematical accuracy needed for brake and spoke holes, all of the drilling and threading takes place after they get their colors. And the final step in the process is laser engraving. Everything down to the spokes gets a mark. Another fascinating procedure to watch.

Nobody builds ’em like Shaq.

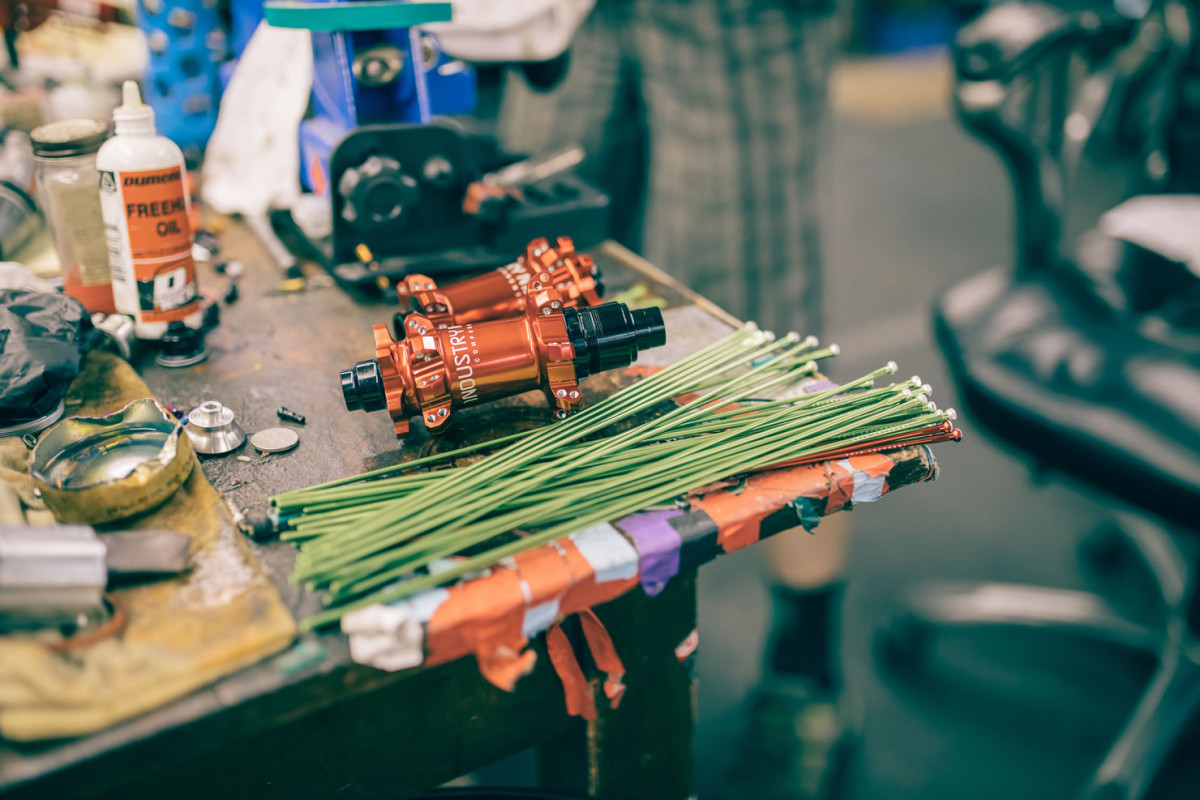

We wrapped up the factory tour and I was paired up with Ricky Muehl, a I9 wheel building veteran of 7+ years. As we picked spokes, valve stems, and hubs for our demo build I secretly wanted to brazenly choose an array of ano colors that resembled unicorn vomit — even though I am red-green colorblind. However, I illogically opted for a red hub on each wheel laced with 30 LimeGreen spokes, a red valve stem, and two red spokes to frame the stem.

Wheel building is indeed a meditative process. Watching it at least. I’ve never actually built one, although I aim to one day. But Shaq pulled it off like he was playing an instrument. I posted a few ‘stories’ as the wheels were being built on Instagram and tagged Ricky, AKA @shaquille_owheel. Within minutes someone responded, “Nobody builds ’em like Shaq.”

Locals Only.

A few days later I brought my dirty Pony Rustler in to a local shop for a cassette swap. After seeing the shiny new I9s and confirming that I hadn’t ridden them yet, the mechanic touted, “They’re unreal, it’ll feel like you added another gear to your bike.” Everybody around these parts seems to advocate I9 wheels, you can’t go a Saturday in Dupont State Forest, Pisgah, or Bent Creek without seeing a pair in action. Obviously, part of that’s based on the need for a good ratcheting hub here. Pisgah is a maze of technical rock gardens, roots, and old hiking trails full of required body english. But perhaps it’s a little more than that too. Around here I9s are legendary. Maybe they’re like the war hero that’s come back to a small town, or the one person from farmville Iowa who became a singing sensation. Either way, it’s pretty special to know that you’re riding something created, built and tested based on trails that have made and challenged you.

Stay tuned as we report back in the spring with an in-depth review of our test wheels — Back Country (BC) 450 rims laced with green (and two red) spokes to red Torch Hubs. And make sure to play around at the AnoLab for your own custom color configuration. In the meantime, here’s a few more pics from our visit and a QA with Chris containing a few interesting tidbits…

What does Industry Nine stand for as a company?

Making the best functioning, best looking, and highest quality product on the market with a strong commitment to manufacturing as much as we can in house.

Industry Nine wheels are known for their superb quality. In a nutshell, why is that?

We pride ourselves on our relentless attention to detail. Having the manufacturing in house allows us to make constant improvements in both design and processes.

What makes I9 wheels better than others?

Our Torch Hubs have the fastest reliable engagement, with the best strength to weight ratio and responsiveness due to low weight and stiff design. We think the have the best style and looks out there too.

Where do you think bikepacking and adventure fit in to I9’s future, or the bike industry for that matter?

I think we are seeing a nice shift in the industry to more “adventure riding” and I think it is here to stay. There are no entry fees in the backcountry and we will keep making stuff that won’t leave you stranded out there.

Everything — down to the tiny pawl springs — within I9 hubs are made in Asheville, NC; your spokes and other parts are made there too. What made I9 decide to add non-US made rims to their product line?

There are no contract manufacturers available in the USA for the volume we need. We also don’t have expertise in rim manufacturing like we do with all of the other components.

Which is your most popular rim, and why?

Enduro305 it is just a badass, do everything rim. The proper balance of light and strong and 30.5mm width just feels really nice on the trail.

Any exciting products or plans coming up for I9?

We have a few things up our sleeve. Expect some cool stuff by next summer.

Who owns the belt on your in-house jump track?

Thunder Joe Haley

What’s your favorite local trail?

There are so many great trails all around us, we could list a few. But folks around here seem to always gravitate to Squirrel Gap.

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.