Inside Kitsbow

We recently toured the Kitsbow facility and got a crash course on what it means to make clothing in the USA and be on the cutting edge of compostable (and minimal) packaging, sustainable manufacturing, and revitalizing the lost textile industry in a western North Carolina trail town. Read all about that, plus mini-reviews of some of our favorite Kitsbow gear and how to get a discount on their apparel through our Bikepacking Collective membership…

PUBLISHED Oct 19, 2021

By Logan Watts & Virginia Krabill

Some readers might shrug off an article about the inner workings of a high-end cycling apparel company. The usual comments will likely ensue about how you can find much lower-priced non-bike-specific garments on the interwebs, that some folks can’t afford such clothing, or that you should only buy secondhand if you’re truly concerned about sustainability. Those points may be valid, but there are a few good reasons why Kitsbow has become one of our favorite apparel companies. Aside from being our neighbors, they make high-quality, classically styled clothing that performs well on the trail, and from our experience, seems to last forever. While we’ve appreciated their gear for a long time, we didn’t understand just how special Kitsbow is until our recent visit to their factory in Old Fort, North Carolina.

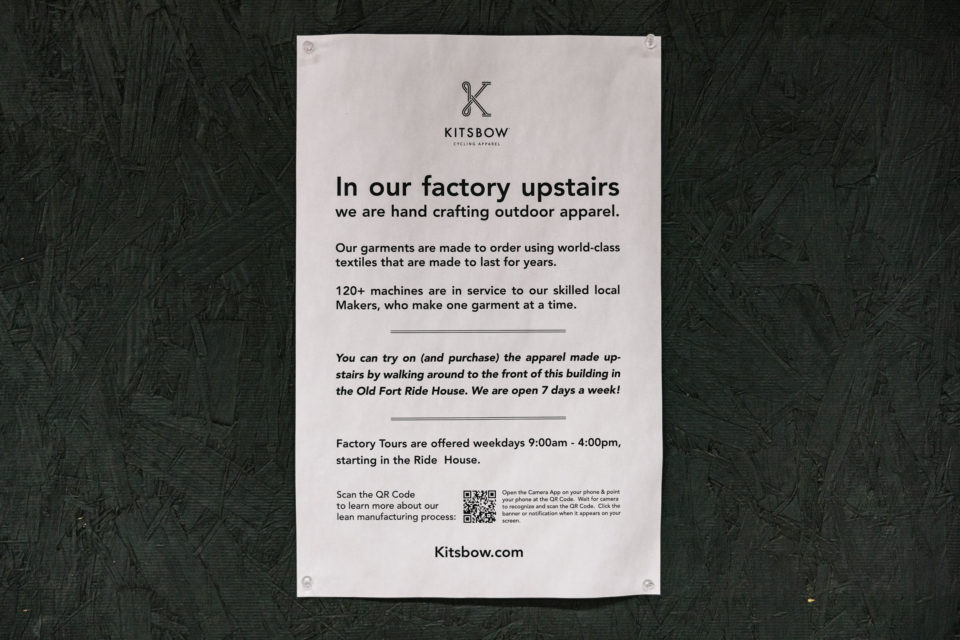

Taking part in a factory tour probably won’t make the bucket list for lots of people visiting western North Carolina, but having taken the Kitsbow tour ourselves, it’s an eye-opening experience to learn and see, first-hand, how one company is making all the right moves in an industry that’s otherwise fraught with labor abuse, poor working conditions, and practices that have a significant impact on our environment. Making their apparel in the USA is impressive enough, but it’s Kitsbow’s unique manufacturing and distribution processes and their commitment to their employees and local community that are most laudable. In short, Kitsbow has made a success out of manufacturing made-to-order clothing of the highest quality, all the while helping to revitalize a nearly forgotten town, support local trail development, and eliminate waste and plastics along the way. Kitsbow is proof that conscientious business practice and financial success are not necessarily mutually exclusive, and we hope that more companies in the cycling industry will take a page from their playbook.

Read on for our interview with David Billstrom, Kitsbow’s CEO (and particularly insightful tour guide), photos from our tour, and a quick look at three of our favorite pieces of Kitsbow gear, one of which we’ve put some 7,000 miles on.

The growth of US textile waste outpaces every category of waste. Driven mainly by a shifting consumer mindset that once viewed clothing as a durable good, but now sees it as disposable. —From Kitsbow’s “Our Reasoning is Circular”

“Lean manufacturing” is a huge component of your business model. Can you briefly explain what that is and what it means for Kitsbow’s consumers?

David: Lean manufacturing is a broad concept that encompasses making products in a “one-piece-flow” rather than in batches, as well as minimizing or even eliminating inventory of raw material and subassemblies, which in turn minimizes the cost of handling inventory and storing it.

Lean is nearly unheard of in the apparel segment, although there are a few others doing it. There are multiple benefits to the Kitsbow customer. At the top of the list is the satisfaction that Kitsbow product is never sent to the landfill when it doesn’t sell. Researchers and experts estimate the all of the other brands worldwide destroy between 30% to 40% of all the apparel that they make when it doesn’t sell. This is a direct result of manufacturing in batch mode, making “bets” on which styles, sizes, and colors will sell. Lean manufacturing avoids this horrible waste.

The second implication of Lean manufacturing in apparel is that the efficiency of one-piece-flow versus batch (even before including the costs of the waste) is so good that we can afford to make our products in the U.S. This has several huge advantages. Namely, the customer’s cash stays inside the U.S. economy, carbon depletion of international shipping (whether by boat or plane) is eliminated, and workers in North Carolina get an outsized portion of the consumer’s cash relative to factory owners’ take in overseas locations.

The third implication is that the customer gets sizing and fit choices that are rarely available from a small brand. Because we make one piece at a time, we can make an XXXXL shirt or an XXS shirt without stocking all sizes and all colors. We simply make the desired size/color/fit when the customer buys it. Other brands working in the bulk model have to order hundreds if not thousands of larger size runs, or simply not offer inclusive sizing.

Kitsbow’s apparel isn’t inexpensive by any means, but how have you managed to keep the prices as competitive as you have? Can you briefly explain how or why having US-made apparel can actually be cost-effective for manufacturers?

David: Things are not always as they appear. For example, our bib shorts are well regarded by our customers and professional reviewers, with all kinds of positive reviews. We use the same top-of-the-line chamois pads (from Italy) as our fellow premium brands Assos and Rapha. Yet our premium bibs are priced less than theirs, even though ours are made in the U.S. (and have been since 2018) and theirs are still made overseas.

Our labor is paid more than the median wage for our region, and also includes 100% employer-paid health insurance (Silver and Gold packages). How can we do it? Because we’re using the inherently more efficient one-piece-flow of lean manufacturing, rather than bulk manufacturing.

We can’t really answer your question, because we don’t understand why any premium brand wouldn’t manufacture in America and pay a good wage.

Can you tell us a little about the actual manufacturing process, specifically the “one-piece-flow” construction you mentioned above?

David: One-piece-flow is simply described as making one piece at a time, rather than assembling subassemblies. For instance, sew two cuffs, and then sew one cuff onto each sleeve, then attach each sleeve to the body of the shirt, and so on. Bulk protocol means sewing 300 left cuffs while another operator sews 300 right cuffs, while yet another operator sews sleeves to bodies, and so on.

While intuitively it may seem that an operator can quickly and efficiently sew the same thing the same way (300 sleeves) for an eight-hour shift, going faster and faster with familiar actions, the research is unequivocal and definitive: the labor to handle those sleeves, stack them, and transport them to another station for next step in assembly not only cancels any efficiency with the repetitive action but adds significantly to the labor time. Furthermore, the repetitive action encourages injury to the human, and mistakes are amplified (300 wrong sleeves!).

The research is well-established in the general concept of one-piece-flow (60+ years) and, in fact, is the manufacturing standard in almost every other industry. Furthermore, one-piece-flow permits different sizes, different colors, different fits (long tights vs. regular tights) to be manufactured in the flow. This broadens the choice that can be offered to the customer, even with a relatively small operation.

Our Favorite Kitsbow Gear

Kitsbow has developed a loyal following that’s evidenced in our local Pisgah scene. I’ve talked to a few folks who wear the brand almost exclusively. Obviously, buy local and made-in-the-USA both play a key role in this. But another point is that Kitsbow’s clothes are extremely durable. In fact, as referenced in the quote above, Kitsbow refers to their clothing as durable goods. Once upon a time, clothing was generally considered a durable good, but currently, the average article of clothing is worn only for a year (or a season, as it were) before it’s tossed in the landfill. Kitsbow’s apparel is designed to last, which we’ve proven through a lot of use. Here are our top picks, one of which I have somewhere around 7,000 miles on, and they’re still going strong:

The Icon Wool Shirt

As you’ve probably guessed from various awards and favorite posts over the years, the Icon shirt is hands down our favorite Kitsbow garment. The long sleeve snap-button shirt is made from US-sourced Pendleton wool and has a brilliantly designed fit with vents and reinforcements. It’s one of those pieces that gets better with age and just won’t quit. I’m now the proud owner of two of them, and they’re pretty much the only thing I wear all winter long. The Icon is available in women’s and men’s (signature fit, which is like the original; and relaxed athletic fit, which is slightly broader).

Details at Kitsbow:

Women’s Icon

Men’s: Signature / Relaxed

Haskell Shorts

Equally as impressive is the Haskell short. I haven’t tracked it to 100% accuracy, but when I piece together all the bikepacking trips on which I’ve worn my nearly four-year-old pair, as well as the countless trail rides, I think I have close to 7,000 miles on them. They are still in great shape, barring a hole in the righthand mesh pocket, which Kitsbow says they’d repair. They’ve changed the Haskell a little since I got them. This pair is the original, which was about 10″ in length. Now they’re available in either 8″ or 11″ lengths. I recently picked up a pair of the 11″ versions to try out and they fit and feel quite similar, so I foresee a long and happy relationship with them. Unfortunately, the Haskell is only available in Men’s sizes/fits at this moment.

Escalator/Lory Merino shirt

While the Escalator and Lory Merino long sleeve shirts are the newest Kitsbow garments in our arsenal, they’ve quickly impressed us and are some of the more useful and bikepacking-relevant garments in their lineup. I’ve always carried a long sleeve merino T-shirt on bikepacking trips, providing an extra layer for cold nights or chilly morning rollouts before the temps have warmed up enough to wear a T-shirt. The Escalator (men’s) and Lory (women’s) merino Henleys and crews are perfect for such occasions. They’re slightly more stylish than a simple long sleeve T-shirt, making them double as a base layer or a single layer. And like other Kitsbow garments I’ve tried, the fit is spot on.

Details at Kitsbow:

Escalator (men’s)

Lory (women’s)

There are a few other items in the Kitsbow lineup that look promising for bikepacking. For example, the new Mullinax and Laurel Mountain 3/4 sleeve merino shirts like quite nice. For more of their products, dig in over at Kitsbow.com. Bikepacking Collective members, be sure to scroll to the bottom of the article to find out how to get a one time discount, too.

The quality of materials and artisanship in each Kitsbow garment is nearly unrivaled from our experience. The clothing is meant to last, and it does. Even so, you all offer free repair services. Aren’t you just cutting into your ability to turn a profit and sell more products?

David: Yes, we are cutting into our ability to sell more products, and the repairs are essentially at a loss even when we charge a fee (if you break your clothes, we charge you a fee. If they wear out, it’s on us). But it’s the right thing to do. We all need to live on this planet, and we need to treat our planet better than we have in the past.

The environmental and sustainability initiatives that Kitsbow has put into place are impressive. A major part of that has to do with lean manufacturing. But beyond your manufacturing process, you all have put a lot of work into cleaning up your packaging. Can you tell us more about that?

David: About six months ago, we took the next step on our sustainability journey, and converted all of our packaging to consumer-compostable material. This means you can bury it in your garden (your typical “compostable” beer cup requires a commercial composting process). And we mean everything, including the translucent bag the garment comes in, the tags on the garment, the box or shipping bag that the garment comes in, the shipping label, the barcode. Everything is compostable.

Also, we have an open offer to share our suppliers with any other brand. We can’t save the planet if tiny Kitsbow is the only one using responsible packaging. We’d be delighted if our packaging quickly became standard, and was no longer a differentiator and a reason to buy Kitsbow.

But, in the meantime, this is simply capitalism at its best. We’re doing this expensive, hard thing because it is both the right thing to do and because we think our customers will buy more gear from us.

Do you have any hopes for the future of the apparel industry? Do you think more sustainable manufacturing is something that might catch on?

David: We think making clothes overseas and shipping them to the U.S. in bulk is not a great idea for anyone (other than the factory owners overseas). We hope all brands convert to sustainable, efficient, locally made apparel. In the meantime, we’re happy to be one of the leaders in this concept. We’ve proved that it works.

The textile industry has a long history in the southern United States, specifically in North Carolina. Did that history play a part in Kitsbow’s decision to move from California to North Carolina?

David: Indeed, our thread comes from 90 minutes away from Old Fort, where we sew. Our compostable boxes for shipping are nearby too. Some of this is due to the historic textile industry, but our primary choice of location focused on two factors: a resilient, hard-working labor force in the Appalachian region, and the stunning physical beauty of the land and trails for our employees to enjoy. Quality of life and hard work with a sense of pride for quality. It really is that simple.

Old Fort is a tiny town, kind of the classic two stoplights and five churches sort of place. How did you decide on this town?

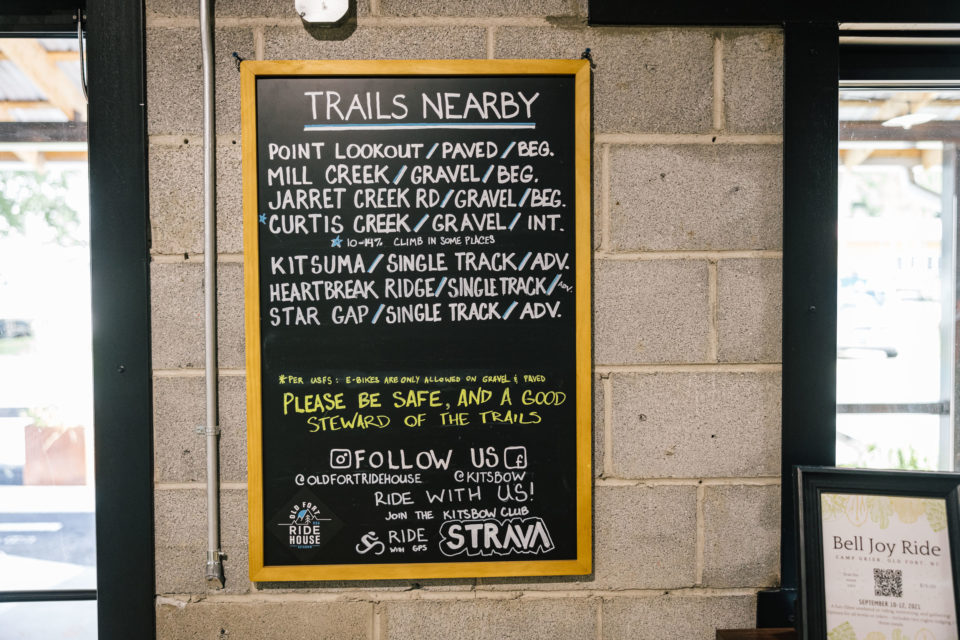

David: We call it the “goldilocks” location. It’s a 20-minute reverse commute in a car from Asheville, one of the most desirable living locations in the U.S. A labor force in the thousands all around our town for a radius of a reasonable commute on country roads (or Interstate 40). Rural cost of living, but two hours from an international airport (Charlotte). And 25% of the county is federal land. Public land is accessible two miles from our front door (you can walk to the national forest!).

We think Old Fort is a gem, and after a 30-year decline, it’s turning around. To be sure, Kitsbow has played a big part in that turnaround (almost exactly two years ago!), but we’re not alone. This is a community, and it is moving forward consciously. We think this will be a “trail town” not in the classic sense, but in a more conscious way, with full-time residents outnumbering absent second homes (because we have factories, not just tourism), with teachers and firefighters living in the town rather than being priced out, and leadership provided by the very people systematically excluded from the community and decisions in the community for the first couple of hundred years.

How do you feel about rejuvenating, even on a small scale, an industry so tied to this place?

David: We’re a relatively clean industry, and there are many such industries that depend upon workers that are highly skilled, building careers, not just filling hours in a job.

How difficult has it been to find and train the craftspeople who work here in Old Fort?

David: It has been difficult because we can’t simply hire “production workers.” They need to share our values, be deeply curious, not only accepting constant change but embracing change.

What is Kitsbow doing to support its employees and strengthen the community of Old Fort?

David: We have multiple health-oriented benefits for our team members, but above all, we offer training and opportunity. We don’t care much for credentials, resumes, or formal education. Our focus is on attitude, curiosity, and commitment. That becomes an extraordinary opportunity for people who perhaps have been left out of the leadership in many businesses.

The Icon has been a Bikepacking.com editors’ top-pick for gear of the year and is one of the favorite shirts of several of our editors. Are there any upcoming products you can share that you’re particularly excited about?

David: We have just revised our Rockstacker technical tight for the third time, and it’s better than ever—and in two different fits. So, that’s exciting. Most of our female customers are delighted with the new variant of our merino top, with three-quarter-length sleeves as an alternative to the classic short sleeves. This extends the season, and it looks pretty sharp too. We’ve also got new tights suitable for not just riding, but yoga and running, coming soon for women. These merino tights will have the legendary Kitsbow fit, and of course be offered in multiple lengths (because we have one-piece-flow, that’s easy). We’re pretty excited about a new alternative for women. Which, by the way, we haven’t served nearly enough with choices, so we’ve got multiple projects underway to give women more offerings in 2022.

Is there anything you want to add about inclusive sizing?

David: We’ve added XXS at the smaller end of the sizing spectrum, and XXXL and XXXXL at the other end, and we’re making these additions very carefully. It isn’t enough to simply make them “bigger.” Our commitment to legendary good fit means that our larger sizes are going to perform in an athletic environment.

We already have this for technical tees, but we’ll soon have these for our mid-layer Lory and Escalator merino tops too. We already offer the Icon shirt in a Relaxed Athletic Fit that’s perfect for the larger person who wants our performance in the outdoors.

For more on Kitsbow, be sure to check out Cass’ long-term review of the Icon shirt, a mini-review in our cycling flannels roundup, and a review of the Haskell in our shorts roundup from last year. Also, make sure to dig in to the 36 Hours in Kitsbow video series, an incredible effort on their part to promote local bike adventure and make space for a variety of perspectives in cycling. Find them all at #36-hours-in-kitsbow.

Bikepacking Collective members: To kick off this story, Kitsbow was kind enough to provide a 20% off discount code for our supporters. This discount code is only applicable on Kitsbow’s Sewn-in-USA collection—which includes all the great gear mentioned here—and can only be used one time per customer. Members can find the code in the “Membership Benefits” tab when logged in and use it at checkout. This discount will expire at the end of the month (October 31, 2021).

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.