We Are One Composites: Hand Laid in Canada

We Are One Composites has been manufacturing high-quality carbon bicycle rims since 2016 in Kamloops, British Columbia. We stopped by their small facility for a quick tour and and a chat with owner Dustin Adams. Plus, some thoughts on the new 27.5+ Convert wheels and Da Package bar and stem…

PUBLISHED Aug 22, 2019

We Are One Composites might not ring a bell for some of our readers, and being the primary Canadian writer here on the site, I’m embarrassed to say that just a few months ago it didn’t for me, either. Thankfully, I’m quick to take recommendations from those who have been in the industry longer than I, and after hearing only positive things about We Are One, and wanting to support a growing Canadian company, I was keen to get my hands on some of their carbon for my recent Why S7 build. More specifically, a wheelset from their new Revolution lineup, the 27.5+ compatible Convert, and their newly released bar and stem combo, Da Package. After a few months spent riding with both, I’ve put together my first impressions, which you can read below. But first, a Q&A with owner Dustin Adams to learn more about his company, their products, and where they’re heading.

We Are One Composites isn’t the first business you’ve owned, right? Tell us about your past and how you ended up making carbon bike components in Kamloops.

I guess business for me started when I was racing bikes. It is a form of entrepreneurship for sure. You need to be aggressive, build your brand, get in front of the right people to grow. After racing, I tried a career in the trades and found myself constantly picking apart the jobs and companies I was working for, looking for efficiencies and how to improve processes. So after a few years of testing, I decided to open up a countertop business. I grew that company for eight years and sold it in 2013. I learned a lot about management and automation. We were one of the first CNC stone shops in British Columbias’s interior and I took a crash course on how to operate and program the machines from day one. It was a real eye opener into what manufacturing was all about. Scrap rates, time tracking, playing the long game for efficiencies, and a whole lot more.

After we sold the company, I took some time off and found myself really missing the bike world. Bikes were my passion and I needed to get back into something to do with them. One of my old customers from the stone days had posted an ad on Facebook looking for a manager for the wheel brand Nobl Wheels. I DM’d him and met with the owner, we came to an agreement, and things progressed really rapidly. After just two months, I purchased 15% of the company and invested into the business. We worked with our manufacturer and visited the plant and I was brought right back to the days when I was working for the trades companies. There was a ton of efficiencies and improvements to be made, but nothing was really being done about it.

Our partnership fizzled due to some direction plans I did not agree with, and being the minority stake holder, I decided to leave and start something on my own. But this time I put all my previous experience into the planning, and that was how We Are One was born. It was my vision that we could compete on a world stage and produce an industry leading product right here in Canada. We had unreal resources just south of the border from prepreg vendors, and all the tools necessary to make a run at it.

I hear the company has experienced massive growth over the past couple years…

When you come from zero, growth is going to happen for sure. The road has been a very hard one and we have had to manage and adapt to more than 100% increases annually since we started. Our team has grown with our sales and we are learning more and more every day about how to improve and continue to provide a product that is high quality with the service to match.

It’s rare to see made-in-Canada bike components these days. How are you able to pull that off, both financially and logistically?

It was a big risk for me personally. I initially sold everything I own. My house, vehicles, anything I did not need in my life to live and move this company forward. My family was super supportive as we moved from Squamish back to Kamloops. This was the hardest part as my kids and wife really had become attached to Squamish and continue to miss it there. I owe everything to them for allowing my to follow this dream.

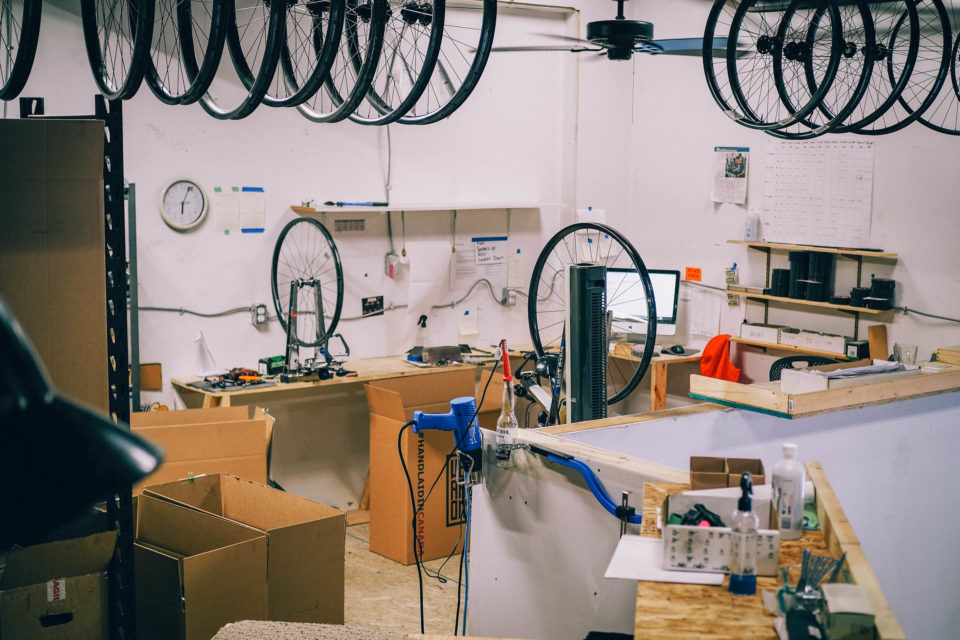

With that money in hand, I lined up the equipment I needed, found a lease space we could grow into that was cheap, planned out six months and a year of needed financing, and kept a crazy tight budget. The original team was assembled with four really keen riders who wanted to share my vision and do the unthinkable. They all poured their hearts into We Are One and we acted like that for the first year. We had so many great milestones and major setbacks all in the first year. I wouldn’t trade that year for anything. It was such a major growth year for the company and me personally and the team involved.

You offer a “No Questions, Lifetime Warranty.” Tell us more about that.

We feel that if you manufacture the carbon part properly and fully utilize the characteristics of the material, you will never have an issue. With all of our testing done here in-house, we have gained a mountain of data and pushed out design further ahead with some fantastic engineering. We have managed to layup, repeatedly, the same results from rim to rim and understand where we are in the market comparison of others. With all of that knowledge we want to put our data on the line and support our customers with a warranty that is actually industry leading and not covered in fine print and wishy washy language that causes confusion of where you stand as a consumer with our policy.

You break it or it fails, we replace it. Simple and to the point.

You have two different lines of rims and wheelsets, the new Revolution and the Movement. Can you tell us a little about each and what differentiates the two?

The company started with The Agent and The Insider rims. Both are still a fantastic product and continue to be our best selling rims to date. But we have learned a ton with that product and felt like an evolution was due. We needed a larger offering that rounded out the demands of the mountain bike consumer and to enter into the gravel market as well. So with the knowledge from the Movement line we created The Revolution line. The Revolution line is our revision and improvement to what we started with and has all of our latest layup and ride characteristics we wanted out of our rims. That said, we still felt like it would be a waste to bin The Agent and Insider molds. So we put them into the most competitive price point on a carbon wheel on the market. 999$ USD buys you a great proven rim on an Industry Nine 101 hub, all backed with a lifetime warranty. It can’t be beat!

There are a lot of carbon rims out there right now. Tell us a little bit about what makes your carbon rims special.

Not all carbon is the same. Carbon fiber has so many different characteristics and comes in almost infinite resin systems that can be tailored to your specifications. Where we differ is in our resin system, the way we process the fiber, and our layup. The resin system is important because that is what holds the whole thing together. You need a completely different set of demands from a rim as you do a frame, or a plane wing or fuselage. Because all we do is make rims, until this year, we were able to select the ideal resin system with a fiber that is well known as one of the best in the industry and tailor this to our needs. Impact resistance, sheer strength, and modulus were all custom made for this purpose.

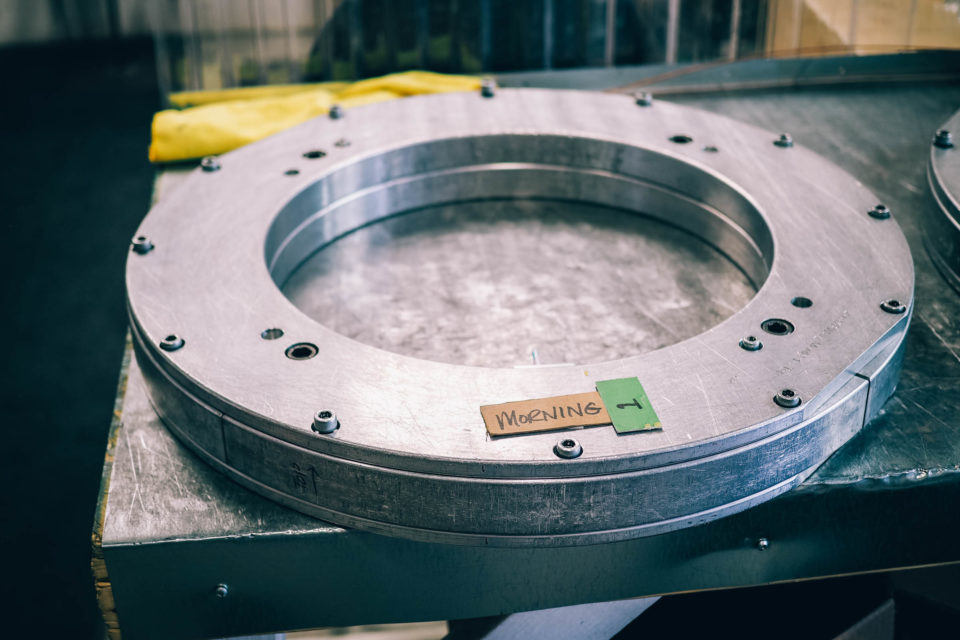

The way we process our fiber is really key as well. When you need to ensure rim to rim consistency you cannot rely on anything but CNC cutting. We are plus or minus three grams from rim to rim on our models. The layup is something we only do here as well. We layup directly into the finished mold and cure in the same mold. There is no pre molding and then placing into a female mold that creates the finished part. This process was developed to ensure our rims were out of the mold ready to sell. When you layup carbon fiber there are challenges of what is possible due to the shape of the mold you are trying to use to make your part. With any good quality part you want to place your fibers as close to their final resting spot inside the part as possible. Drift is what you are trying to reduce. Drifting refers to your fibers slipping between layers, until the fibers are in their final resting place. If your fibers drift, you will have no control over where they end up and what characteristics they bring to the part. It can create wild swings in quality and strength of the part, especially when working with unidirectional fibers. So our molding process and layup only allow for .5mm of drift to complete a part. Everything we place in the rim is exactly where we want it. This is why we can consistently produce the same rim over and over again. It is a very expensive way to process as we need way more molds to scale production.

Tell us a bit about your new bar and stem package, Da Package.

Ahh yes, Da Package buy. It’s best kind no doubt! (read in your best Newfie Baymen accent)

This was a great collaboration with Giacomo from 77designz. He is a great designer and owns a component company in Germany. We became friends at the BC Enduro series a few years back and he came to us with a project he wanted us to help with. The original concept was great and we added some ideas like the bar nipple to catch the aluminum sleeve and went to work. The bar was a ground up project here for us and took over seven months to complete. We built a custom test rig where we run fatigue and yield strength tests on bars to find a baseline and then build our bar around besting the EFBE downhill bar test. At the time, we had plans to use the stem from 77designz, but I got cold feet and thought that our vertical integration would not work with a sourced stem, or would it stand with our Made-in-Canada ethos.

So we developed our own stem and tested it in conjunction with the bar on our rig. We passed the EFBE fatigue test well above their max yield. This gave us the ability to tune back the stiffness of the bar and zero in on ride quality and feel for the rider at the grip. The layups were optimized and we can confidently say that this is one of the nicest feeling and strongest bar and stem packages on the market today. Weighing in at 338g for the 35mm complete package it is also at a weight that you cannot overlook. I am happy with the way the project was run, the collaboration with Giacomo, and with the finished result. It was a great journey to come from concept to sellable SKU and I wouldn’t have done it any other way.

I was quick to notice the lack of branding on the new bar. Is there a reason behind that?

This was a concept I wanted to test. I feel that bikes and components are fastly becoming the “TAP-OUT” T-shirts of a few years back. Clean and simple is what I feel most people with style appreciate and I wanted to see if that was true. My thought was if you ride past a rider and you can already see what selection they made based on logos, what is the point of having a conversation with that person. You already know and have judged his or her selection and moved on.

Without logos or branding, people are going to look at Da Package and want to know more. This gives the customer an intimate connection to our brand and they get the chance to share their experience with another rider. These interactions are what We Are One is all about. It is in our name and in our thinking as a company. We want all of our customers to share great experiences with others so they can also join The Movement and feel apart of something larger than just shelling out dollars for a product.

It’s clear that your focus has been on keeping things local, even beyond the manufacturing side of things. Why is this so important for the foundation of We Are One?

We need more makers in this part of the world. When I started the concept of We Are One, my goal was to show what was possible locally and to inspire others to step out of just product design. Design is a massive element in the process of making a significant part. But if you never get to make it with your tools, hands, and material of choice, what connection do you have to that product? You can ask all of our employees here in the shop, every one of them has a deep satisfaction in making something every day. They get the joy out of knowing someone will appreciate what they have done, and when you see the product on another bike out on the trails, they get the connection. This concept has been missing in North America ever since we started off-shoring all our manufacturing, and I wanted to be a part of the push that shows we don’t always need to pass it over. You can do it right here, and better.

You know, my grandfather built ships in Vancouver, and my mother used to tell me stories about the hard work and dedication that my grandfather and his brothers put into each vessel they built. It was a deep sense of family and pride for them. As the years went on and I grew older, I watched that passion burn inside my grandfather, but at the same time, he looked lost and disconnected. His passion was off-shored and the company they started moved on. It was hard to watch a man who dedicated so much to building something lose connection to his passion. I wanted to follow in his steps and build something that we could put our name on and be proud of. I feel We Are One is that vehicle for me, and that all the people involved in the company have that same vision.

What’s next on the agenda for We Are One?

We are a company of firsts. First manufacturer in Canada to produce a carbon fiber mountain bike rim, first to produce a carbon mountain bike bar, and we will continue. We are in the early stages of a bike frame and will hope to have something to show the public in 2020. I want to build as many components here for our bike and sell a bike that offers something no other company can when it comes to carbon fiber.

The Convert Wheel: First Impressions

As part of We Are One’s new Revolution lineup, the Convert is their wide format offering, designed specifically for larger tires for stability and traction. With a recommended tire width of 2.5” – 3.0”, and availability in both 27.5” and 29” diameters, I was almost immediately set on my rim. Complete wheelsets are now built up with Industry Nine Hydra hubs and 32 hole rims as default, although custom builds are available, so Dustin was happy to track down some green anodized hubs to match some other bits on my Why S7. Right from the start it was clear Dustin and his team are in tune with what riders want, being riders themselves, and made sure I was getting the most ideal wheels for my needs. If plus-sized tires isn’t your thing, they have other rims in the new lineup ranging from xc / gravel with 2.1” tire compatibility all the way up to full on downhill rims designed to take a serious beating.

Upon receiving my Convert wheelset, and unboxing them in an excited hurry, it was immediately clear that We Are One is paying close attention throughout all of their processes. They were packaged securely and cleanly and their carbon finish is excellent. On the inside, the included rim tape provided great coverage, and almost appeared seamless at first glance. Under the tape, you’ll find your rim’s serial number, build date, and your wheel builders initials. It was fun to ask the few employees hanging around after close, during my tour, if they remembered who built my Converts – and all were quick to chime in, commenting on who was responsible for the carbon layup and the wheel build itself. The entire team is passionate, and it shows.

Setting up the Converts tubeless was straightforward, as they arrive with nothing else to do besides install a tire and add some sealant. I first installed a pair of 27.5 x 3.0” Terrevail Coronados, but the clearance wasn’t where I wanted it on my Why S7 frame, as the finished width ended up being closer to 3.5” on the 35mm internal width of the Convert rims. So, within a few days I swapped those out for some 2.8” Cumberlands, a little smaller, a little chunkier, and likely a better option for singletrack-focused bikepacking. In both cases, they set up tubeless immediately with some help from an air compressor, and even before adding sealant, the tires held air well enough for me to ride around the shop a bit. Although that’s a sign of a good tire, it’s also a clear indication that the interface between my chosen Teravail rubber and Convert rims is spot on – potentially avoiding issues down the road. Since then, I’ve reseated tires on the Converts effortlessly with a floor pump, as well as the recently reviewed Milkit Tubeless Booster. The shallow, hookless bead area on the Convert is designed with purpose, not only to make installing and seating tires a breeze, but also to reduce the chance of burping (losing air on a big hit or landing, while set up tubeless) the rim, even at lower pressures.

Since then, I’ve been on an overnighter to Britsh Columbia’s Sunshine Coast, as part of the Swift Industries Solstice Campout, tackling a portion of Skyler’s Lower Sunshine Coast route on the return trip. I’ve gotten out on day rides in Kamloops and Kelowna, both of which are dry, rocky, and dusty – very different from the coast’s loamy dark soil and lush forests. Then, on my way back to Ontario to visit family, Emily and I also got out on an overnighter leaving from Bozeman, Montana, following scenic gravel roads and some easy trail. It’s too early to comment on the long-term durability of the I9 Hydra hubs, but it’s worth noting that Alexandera Houchin has been running a Hydra on her rear wheel for this year’s Colorado Trail Race and her record setting Tour Divide ride, and she doesn’t appear to be stopping any time soon!

Although it’s no secret that the weight savings aren’t substantial for wheels of this size, often weighing in close to some high-end alloy alternatives, it’s the quality of ride and added stiffness that really shines through. Paired with I9’s ultra high-engagement Hydra hubs, I’ve never experienced such a responsive ride when climbing technical singletrack or while skirting down a chunky decent. It’s hard to say, but I think it likely comes down to a high quality carbon layup that is both consistent throughout the entire rim and tested against the rigours of downhill riding and beyond. The carbon is manufactured using a mix of woven and uni-directional fibers, forming an extremely strong, yet still lightweight, complete wheel. The shallow walls of the rim are also designed to absorb impacts, which is often the first place we see damage on carbon rims, and would likely result in a trip-altering situation that none of us want to deal with.

Pros

- Made in Canada, support the locals.

- Extremely competitive pricing, worth the investment.

- Superb craftsmanship and attention to detail, that brings a new level of performance to your entire bike.

- Lifetime warranty, that covers all accidents that can happen while riding your bike.

Cons

- Still an investment, so may not be affordable for everyone.

- 2-3 week lead time to ship. Might be a problem for some people.

- Model Tested: We Are One Composites, The Convert Wheels, 27.5 Boost

- Price, As Tested: $1,875 CAD

- Weight (front and rear): 1850g (with valves, and rim tape)

- Manufacturer’s Details: WeAreOneComposites.com

Da Package Bar & Stem: First Impressions

Announced this June, We Are One teamed up with Germany-based 77Designz to create a bar and stem package that sheds all unnecessary weight without compromising strength or comfort. As expected, Da Package is made up of Da Bar and Da Stem. Da Bar is made in We Are One’s shop in Kamloops, it’s a 800mm wide carbon bar with 20mm of rise, 5-degree upsweep, and an 8-degree backsweep. Cut lines were incorporated into the bar’s mold, allowing it to be trimmed down to 740mm if needed. Da Stem, also machined at We Are One, is made from 7075 aluminum, comes with titanium hardware, and is offered in two different lengths; 35mm and 45mm, weighing in at 320g and 338g respectively. As there is no face plate, the bar slides horizontally into the stem, and the two become one via an aluminum sleeve. The sleeve effectively eliminates any harsh interactions between bar and stem, a common problem when running carbon bars, spreading the clamping forces across the entire sleeve rather than a smaller section of carbon. Positioning the internal sleeve and stem is simple due to a raised section in the bar to ensure correct alignment, no guess work needed. We Are One doesn’t specify an exact angle for their bar, rather encourages riders to run it how they prefer, and play around with the angle.

Before swapping over to We Are One’s Da Package, I was running Fatback Cycles Sweet 16 Bar; a carbon bar designed specifically for winter ultra and endurance racers in mind, and also appears in our list of comfort mountain bike handlebars. However, I found the 16˚ sweep a bit too much for the trail-oriented geometry of my Why S7, and felt like I wasn’t getting the reach I needed. Of course, this will differ for everyone depending on your bike and riding style. Da Package put me right back where I wanted to be, while offering the comfort of a carbon bar in such an incredibly clean… package. Da Bar and Da Stem have easily received the most questions from other riders out on the trail this summer, and I’m not surprised.

For those looking to shave a few grams yet still yield the durability of downhill rated components, both the stem and bar are impressively lightweight. Da Bar weighs just 215g, plus another 12g for the alloy sleeve, for a 227g total. The amount of weight We Are One managed to shed on Da Stem is truly impressive, weighing in at just 80g for the 30mm stem and 86g for the 45mm. The full ensemble, Da Package, with the 45mm stem as tested, will add just 338g to your build. To offer some comparison, Industry Nine’s A35 Stem in the 50mm length weighs 135g, Paul Component’s 35mm Boxcar Stem weighs 118g, and another made in Canada option, Chromag’s 50mm Ranger V2 Stem weighs 175g. I’m not one to count grams, but it goes to show you that We Are One is doing some impressive work that’s surely worth checking out.

Pros

- Lightweight, yet still durable enough for aggressive riding.

- Made in Canada. Both bar and stem.

- Unique design and look, sets it apart from the crowds.

- Good combination of sweep, rise, and comfort.

Cons

- Designed together, the stem and bar only work together.

- Higher price tag due to the bar/stem package.

- 800mm is quite wide for most people, but can be trimmed down.

- Model Tested: We Are One Composites, Da Package, 45mm Stem

- Price, As Tested: $375 CAD

- Weight: 338g

- Manufacturer’s Details: WeAreOneComposites.com

Wrap Up

It’s clear that everyone at We Are One is extremely passionate and dedicated. The quality of their rims is unmistakable, and the new bar and stem follows suit. Although We Are One might be a lesser known name among bikepackers, their dedication to made-in-Canada components in an industry dominated by the opposite is refreshing. Considering the pricing on a complete carbon wheelset, built up with I9 Hydra hubs, is under $2,000 CAD, is really just the cherry on top for those looking to support a Canadian company. My experience with the company, its products, and its people has been entirely positive, and I look forward to following them in the years to come.

A big thanks to Dustin at We Are One for making the time for our visit and answering our questions. Also, stay tuned for a closer look at Miles’ Why S7 build, coming soon!

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.