The Dungbug and the Fennek are two of the latest mountain bikes to roll out of the Vetra Bikes shop in Berlin, and we caught up with builder André Roboredo to hear about some ongoing changes at Vetra and check out both new rigs. See more here…

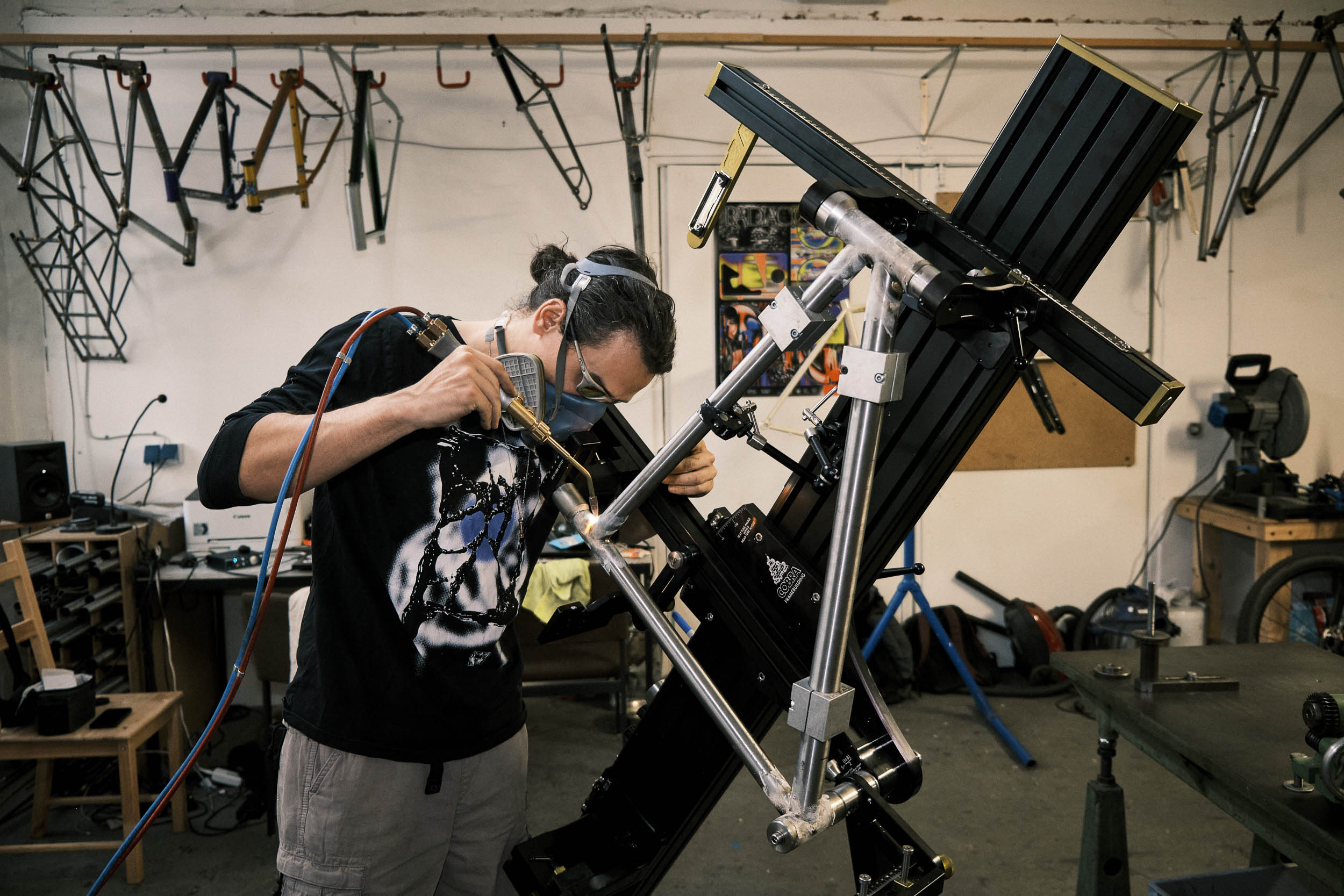

Workshop photos by Josh Meissner

While fabricating some of the most eye-catching and creative bikes on the scene, Berlin-based framebuilder André Roboredo of Vetra Bikes has also been working to streamline his frame production process over the last couple of years. His overarching goal has been to reduce the time it takes to build a frame from 40 hours down to just 16. To this end, he’s figured out ways to keep designs fresh while avoiding overly complex designs and sticking to the “golden number” of eight tubes. This allows for more functional and affordable bikes while still letting his clients engage in the cultural side of building: shaping the bike’s narrative, choosing graphics, and getting involved in the creative process.

Speaking to this process, André told me, “I wanted to make sure that the customization process was still flexible. Most people want a functional, eight-tube bike at a reasonable price, but they also want to feel connected to the bike’s story and design. To keep things simple, I developed four core platforms—All-road, MTB, ATB, and Commuter—that all Vetra bikes are built around. These platforms focus on fit and allow for some customization when needed while keeping the cultural aspect alive. Its all custom in fit and particular functionalities.”

Further optimizing his overall process, he’s also shifted away from wet paint toward power coating for steel frames, only using wet paint for bikes with carbon parts. Powder coating is faster, more durable, and more cost-effective than wet paint, which is more fragile and time-intensive. André is no longer using graphics under the clearcoat, instead opting for DTF (Direct-to-Film) printing to create durable, textured graphics that are more adaptable in process and let clients have more input in the process without weeks of final sign-offs. This way, they can be a part of the creative process and see mock-ups come to life in real-time when the frame is already painted.

Together, all of these small changes enable André to continue building rolling works of art that are tougher and less expensive for all parties without sacrificing any of the quality or distinctive heart and soul that goes into all Vetra frames. This proof of concept is evidenced by a couple of the latest bikes to leave the Vetra shop, Jack’s Dungbug and Melina’s Fennek. Check them out below.

Jack’s Vetra Dungbug

For Jack’s bike, the Vetra Dungbug, the goal was to build something that suited his fit better than the stock Vetra model he’d been using. Jack had some knee issues with his previous setup, so André adjusted the geometry to make sure it was more comfortable for him. He extended the reach a bit so he could swap from a 90mm stem to a 70mm, which lengthened the wheelbase for extra stability off-road, and André made the seat tube angle more neutral, adjusting from 72.5° to 73.5° fore-aft to help with knee alignment and comfort. It’s in a good range for getting it tweaked by the fitter.

André also made sure to optimize the top tube clearance for better frame bag space, and he used flat mount on the rear to make it easy for Jack to switch over parts from his previous bike. Since Jack already had his setup dialed in, André kept things minimal: no unnecessary mounting points, just some eyelets on the rear for a Tailfin rack, and the rest of his gear is simply strapped to the frame.

The name “Dungbug” comes from dung beetles, which are known for carrying loads on their backs. Jack really connected with that idea. For the graphics, he took Christophe’s original Vetra logo and gave it a cool, bug-inspired twist, which André says perfectly fits his personality and the bike’s vibe.

Melina’s Vetra Fennek

Melina’s bike, the Vetra Fennek, was built to match her needs and riding style. She’d been riding a Salsa Fargo, which she loved and had dialed in with a fit at the fitter studio. But then she got a stock Bombtrack MTB with 27.5” wheels and quickly realized the reach was way too short for her. Plus, she missed the stability and plow-through capacity of 29” wheels.

On a bike this size, the inseam height had to be optimized for clearance since Melina would naturally run 27.5” by sizing, as well as for maximum luggage capacity. The main triangle of her Fargo was too small for her, limiting the space she needed for gear. So, André built her a flat-bar MTB that matched her custom fit and could handle 29” wheels. This gave her the stability and comfort she wanted while handling off-road conditions better than drops. André tweaked the geometry to make sure she had proper inseam clearance, which also made room for bigger bags and a dropper post setup.

For graphics, André took some inspiration from the desert landscape, pulling elements from that environment to make the design. Christophe created some custom typography to tie it all together. The name “Fennek” comes from the desert fox, known for being quick, agile, and adaptable to tough conditions—a perfect fit for a bike built to handle anything while still being fast and responsive.

Further Reading

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.