Forever Chemicals: The Rise and Fall of PFAS

Last month, California and New York banned manufacturing and distributing textiles and garments containing PFAS, chemicals commonly found in waterproof-breathable garments. What does this mean for waterproof cycling apparel, the popular membranes they’re made of, and bikepacking gear treated with water-repellent coatings? We spoke to prominent bag makers, fabric manufacturers, and cycling apparel brands to find out…

PUBLISHED Feb 17, 2025

A special thank-you goes to Greg Hardy of Rockgeist, who encouraged me to dive deeper into the PFAS story and helped shape this piece. You rock, Greg!

If you’ve shopped for a new tent or rain jacket in the last five years, you’ve probably come across claims of some being “PFAS and PFC-free.” Previously, this little addition wasn’t much more than a bonus that most consumers, like me, didn’t understand. Aside from acknowledging it was good, PFAS and PFCs were a mystery. However, big changes are coming in 2025, including the ban of forever chemicals like PFAS, which means significant changes for the outdoor apparel and gear we know and love. What are PFAS? PFCs? What are forever chemicals? What’s changing in 2025, and what does this mean for our beloved GORE-TEX jackets and coated bikepacking bags?

To demystify the PFAS story, I spoke to a handful of brands and industry contacts directly affected by the new regulations in the US. But before we can talk about today’s reliance on PFAS, we must first take a trip back to where it all began. Unlike most origin stories in the bikepacking industry, the PFAS story was born in Germany at the chemical and pharmaceutical conglomerate IG Farben… not a garage.

Forever Chemicals: A Love Story

According to the National Institute of Environmental Health Sciences (NIH), per- and polyfluoroalkyl substances (PFAS) are a large, complex group of synthetic chemicals that have been used in consumer products globally since around the 1950s. They are used in food packaging to keep things from sticking, pizza boxes to keep grease from seeping through, and make clothing resistant to stains. There are PFAS in non-stick cookware, including packable camping versions. They’re in many bikepacking bags, too, and they’re also water-repellent, which is why they made their way onto virtually every rain jacket you’ve owned. PFCs (perfluorinated compounds) are a type of PFAS, a broader term that includes thousands of chemicals. For the sake of simplicity, I’ll be referring to these chemicals as PFAS. So, where did they come from?

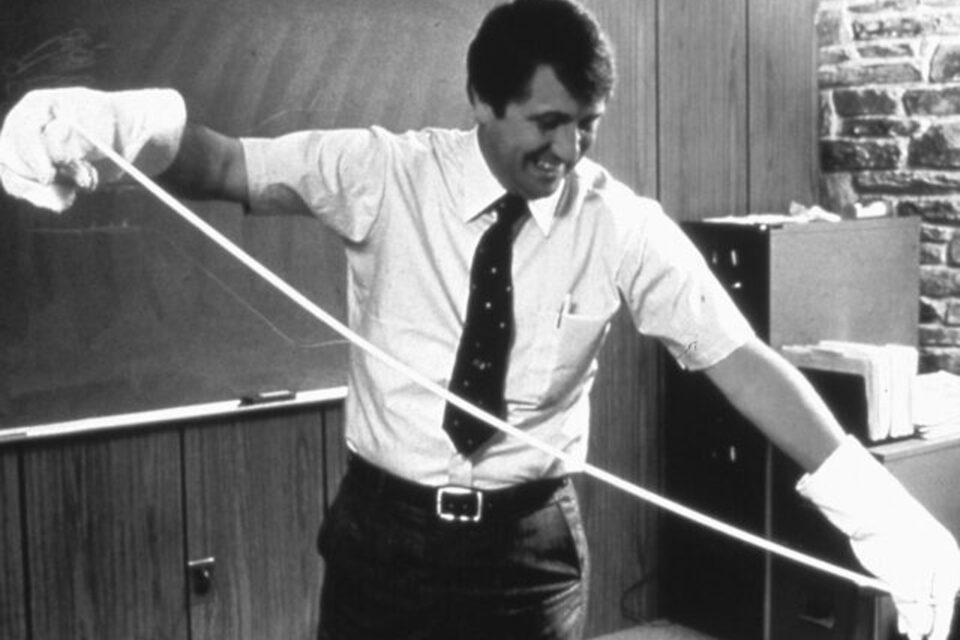

The PFAS story has been a slow burn, starting as early as the ‘30s. It first existed as polychlorotrifluoroethylene (PCTFE), discovered by German chemists Fritz Schloffer and Otto Scherer in 1934. Not long after, Dr. Roy J. Plunkett, an American chemist working for Dupont, was hunting for alternative refrigerant gases and found a frozen, compressed sample of tetrafluoroethylene (TFE), which polymerized spontaneously into a white, waxy solid to form PTFE, a type of PFAS better known as Teflon.

Considered the “most slippery material in existence,” Teflon is used in virtually all industries, including aerospace, communications, electronics, industrial processes, and architecture. Its unique non-stick properties have landed itself in our cookware, textiles, and industrial products designed for harsh conditions. Teflon found its way into apparel, including 3M’s Scotchgard to protect from spills, stains, and water, and it continued to expand from there, including what would eventually become none other than the GORE-TEX membrane.

What’s the Big Deal?

PFAS are often called “forever chemicals” because they’re manufactured, not naturally found, and can take hundreds of years to degrade. Because they are used so widely, they’re found in the water we drink, the ground, and our bodies. One report by the Centers for Disease Control and Prevention, using data from the National Health and Nutrition Examination Survey (NHANES), found PFAS in the blood of 97% of Americans.

The US Environmental Protection Agency (EPA) explains that PFAS may be harmful to human health, but just how harmful is difficult to determine. Current peer-reviewed scientific studies link exposure to PFAS with decreased fertility, developmental effects, increased risk of cancer, and other complications. Determining which PFAS chemicals are harmful and what the impact of prolonged exposure is is difficult because of the sheer number of types, how people are exposed, and the complex nature of tracking them.

Outdoor gear and apparel brands have been eliminating the use of certain PFAS for years. In 1998, a lawsuit started that would eventually lead to the 2016 ban of some of the most persistent types of PFAS, including long-chain perfluorochemicals (PFCs) used in US manufacturing. Following this, Mountain Equipment Company (MEC) permanently removed long-chain (C8) PFAS chemistry from its durable water repellent (DWR) product coatings. As of Fall 2024, 99 percent of Patagonia’s fabric, by weight, with water-repellent chemistries, is made without intentionally added PFAS. The cycling apparel brand Ornot has transitioned to using all PFAS-free DWR coatings. Nemo has been steadily expanding their PFAS-free tent options over the last few years to the point where all off their tents are now free of intentionally-added PFAS, and other gear and apparel brands are following suit.

Some brands avoided PFAS from the beginning; one of the most recognizable is Nikwax. Nick Brown founded Nikwax in 1977 and was described as “anti-establishment.” The original waterproofing formula was unlike anything being used at the time, and when considering the use of PFAS in the ’90s, he found medical studies that showed concerning results. Being a bit of a scientist himself, he decided to steer clear. Before the legislation changes in the US, other brands still wanted PFAS-based product care solutions, but now that the laws are changing, everyone is getting on board. Nikwax launched Direct.Dry, their factory-applied PFAS-free DWR coating, alongside Outdoor Research’s Fall 2024 collection, and they’re working with other brands that should be announced in the next six months to a year.

Heidi Dale Allen, VP of marketing for Nikwax, mentioned something that will directly affect consumers’ relationship with PFAS-free gear. PFAS are exceptionally good at repelling oil and dirt, and newer formulas offer less resistance, so they must be cleaned more frequently and diligently.

Intentionally Added PFAS: A New Hope

Despite many brands switching over to theoretically “less harmful” short-chain PFAS (often referred to as C4 or C6), studies indicate it is no less persistent in the environment, and regulations in Europe and North America are pushing to eliminate PFAS entirely. And now, for the first time, California and New York are banning the intentional use of PFAS as a water, oil, and stain-resistant finish in several consumer product categories. This law just went into effect last month.

What exactly does “intentionally added PFAS” mean? I reached out to the Green Policy Science Institute to find out. They explained that it’s usually defined by a threshold amount on a test for total organic fluorine (TOF). They use TOF as an indicator for PFAS levels because all of the 10,000+ PFAS compounds out there contain a carbon-fluorine bond. It’s measured in parts per million (ppm), and the new threshold in California is 100 ppm for certain food packaging, textiles, cosmetics, and juvenile products. The threshold is supposed to drop to 50 ppm in 2027.

California Assembly Bill No. 1817

After learning about intentionally added PFAS, my first thought was, “We’re doomed!” But Rebecca Fuoco, director of science communications at the Green Policy Science Institute, talked some sense into me. We already have or can eventually develop PFAS alternatives in consumer products. While it will be harder to prevent low levels of contamination in products (e.g. unintentionally added PFAS), the more we decrease intentional uses, the more the opportunity for unintentional contamination also decreases. In short, we’re on the right track.

I also spoke with NEMO’s Theresa McKenney, director of sustainability and gov’t affairs, and Gabi Rosenbrien, product development manager, to learn more about their experience transitioning to a PFAS-free product lineup. They explained that eliminating PFAS from NEMO’s product line was relatively straightforward, but testing for unintentionally added PFAS across their lineup of 200+ products was no easy task. Developing NEMO’s PFAS-free OSMO tent fabric was a multi-year project, but they believe it aligns with the brand’s commitment to prioritizing both performance and sustainability—and ultimately drives innovation in the long term.

A Ripple Effect

I’ve heard mixed stories about other countries’ relationship with PFAS and how things are evolving. The folks at Dyed in the Wool in Poland explained that restrictions on certain PFAS in consumer goods, including clothing and food packaging, have been in effect for over a decade. In 2023, the European Chemicals Agency (ECHA) released a proposal that would effectively result in a complete ban on the production and use of PFAS within the EU, but due to complexity of the proposal, it sounds like it’s still a ways out from being adopted.

In the UK, PFAS has been a big talking point. Graeme Raeburn, lead designer at the cycling apparel brand Albion Cycling, has been busy digging up information and clarity on this subject for years. It all started 10 years ago when C8 DWR’s had been phased out due to toxicity and C6 was being praised as the safe alternative, which didn’t sit right with him. Years later, Graeme learned that the delay and lack of information was being disrupted by chemical manufacturers who were telling their employees it was perfectly safe.

I asked Graeme about the current situation in the UK, and here’s what he had to say: “In terms of legislation and phasing out, it’s quite complex and slow moving. The UN’s Sustainable Development Goals for 2030 have focussed on eliminating the most harmful/toxic/wasteful/inefficient chemicals and processes first, with each UN nation responsible for implementing change, trickling down into individual industries, businesses, and products. PFAS is an example of this, with different groups setting about phasing out in different ways. Currently in the EU (the UK will continue to march to the beat of the EU drum, crazy to do otherwise), there are plans in place to phase out PFAS through all but the most exceptional application (e.g. medical, military, etc.).”

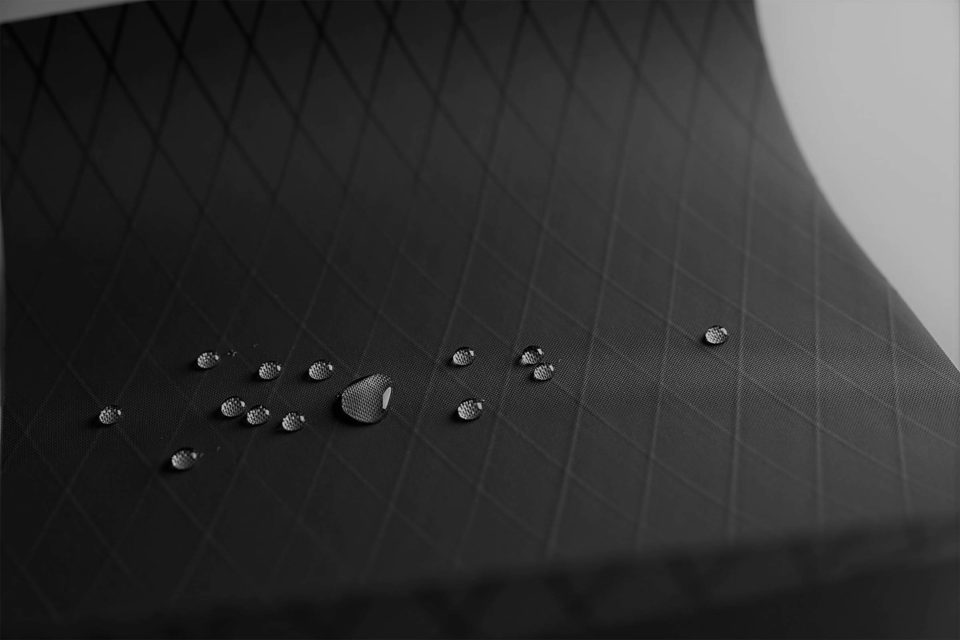

In many ways, the January 1st, 2025, legislation in the U.S. was a watershed moment for the outdoor industry. Graeme explained how important these markets are, so it’s simply impossible to be a quality brand and have a product containing PFAS. Albion Cycling works closely with Pertex, who is actively working toward using 100% PFAS-free fabrics, and a number of their waterproof garments are already taking advantage of PFAS-free technology. For example, the Albion Zoa Rain Trousers I’m currently testing are made using Pertex Shield and Pertex Endurance Technology, which is a non-PFAS, silicone-based application that they claim outperforms traditional DWR coatings. It’s integrated into the fabric, and as a result is not easily washed or worn off.

Graeme is confident that the current direction means PFAS will be phased out entirely in the consumer market, and he’s especially interested to see what this means from a sustainability/consumerism perspective. Graeme explains: “If you have a older high-performing garment, there will motivation to keep using it, plus more emphasis on caring for/maintaining fabric for optimal performance. PFAS deadstock/vintage items might become highly prized. Athletes might opt to source deadstock PFAS fabric or repurpose vintage garments tailored into new items for particularly adverse conditions. Education and workshops around PFAS-free reproofing and garment care could be a new way to engage with consumers and open up space to consider more sustainable ways to use post-PFAS apparel.”

Introducing GORE-TEX ePE

One of the most notable brands to be affected by these changes is GORE-TEX. If there’s a brand that is synonymous with waterproof-breathable apparel and a long relationship with PFAS, they’re it. This example is unique because GORE-TEX membranes are used not only in their own brand, Gore Wear, but also in hundreds of other brands, including many cycling apparel brands such as 7mesh and Rapha. A change in their membrane has a massive ripple throughout the outdoor gear world.

Bill and Genevieve Gore founded W. L. Gore & Associates in the late 1950s. Bill left his job as a supervisor and head of operations at Dupont because he believed there was untapped potential for PTFE. In 1969, their son Bob Gore stretched PTFE into a thin, incredibly strong, microporous material. This discovery would ultimately become the backbone for modern-day GORE-TEX fabrics.

In 2017, GORE-TEX announced its decision to remove PFAS from its consumer fabrics products and has been striving to achieve that goal. They’re on track to meet their goal of eliminating PFAS from the vast majority of our consumer fabrics products by the end of 2025, which is coincidentally in line with the timing of current regulations. In 2022, GORE-TEX launched expanded Polyethylene (ePE) as a new complementary material platform to serve as the basis for its membrane technologies. Microporous Polyethylene (PE) has been available in various markets for many years. However, PE-based membranes that were suitable in other applications lacked the durability for waterproof, windproof, and breathable apparel.

Gore applied more than 40 years of material and science knowledge to manipulate (expand it and make it more durable) PE to create ePE. The result is a light, thin, strong, waterproof-breathable membrane made without intentionally added PFAS. The ePE membrane is Bluesign and OXEO-TEX 100 certified, has a reduced carbon footprint compared to previous membranes, and utilizes laminates made from recycled and solution-dyed textiles. The minimum hydrostatic head (HH) rating, or waterproof rating, is 28,000mm, which is comparable to GORE-TEX Paclite Plus and GORE-TEX Active and is considered to be very waterproof.

Despite being around for a few years, I first heard about the new ePE membrane from the folks at 7mesh in British Columbia. In fact, 7mesh was the brand that explained the unique opportunity with the majority of brands moving to this new membrane, creating a level playing field. This helped inspire me to dig deeper into PFAS and the new regulations surrounding them. Although these regulations were announced in 2016, 7mesh explained there has been discussion around PFAS for a long time, so the change seemed inevitable. Because they had years to roll out an updated product line, they’ve been able to adapt incrementally, rather than all at once.

I asked 7mesh about how their new ePE jackets and how cyclists will need to care for them, and they explained the main advantage of PFAS DWR coatings is that they’re resistant to oil contamination, while the new generation of jackets requires more care. Users will have to be more conscious of contamination from things like chain lube and even more innocent-seeming things like petting a dog then rubbing your hands with the oil from their fur on the jacket. With that in mind, more frequent washing is a good plan to protect the DWR performance. 7mesh has washed the garments with the new DWR coating hundreds of time and they have shown excellent general durability. On the plus side, ePE membranes are lighter than their current waterproof membranes, so the new 7mesh ePE jackets will be their lightest yet.

What About Bikepacking Bags?

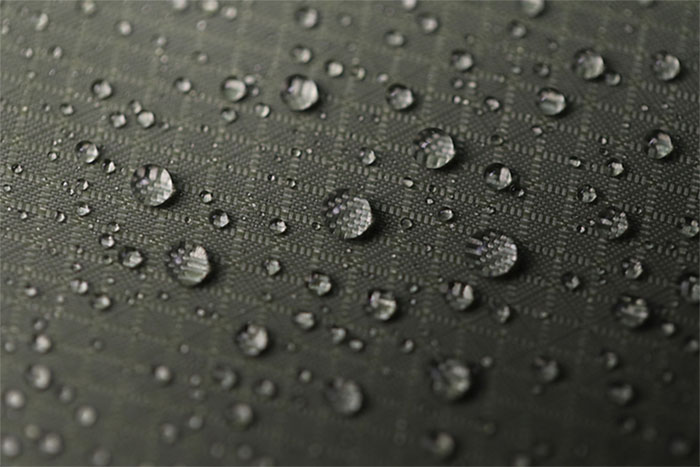

The story of forever chemicals doesn’t end with rain jackets. In the textile world, traditional durable water repellent finishes are made using PFAS, including bikepacking bags made from X-Pac and Cordura fabrics, which at one point were the benchmark fabrics for bikepacking bags everywhere. Fabrics using PFAS alternatives, including X-Pac’s RX line, Challenge Sailcloth EcoPak, and many Ultra-PE fabrics, have been introduced and embraced by bag makers worldwide.

Greg Hardy at Rockgeist has taken a louder stand against forever chemicals than any other bag maker. Currently, about 90% of fabrics they use are PFAS-free, and they are working to only use PFAS-free fabrics by the end of this year. Coincidentally, Greg was the one who had encouraged me to switch from a non-stick frying pan to cast iron a few years ago. While his reasons are rooted in maintaining a healthy body and planet, his opinions on durable water repellent finishes used on bikepacking bags are slightly less common. In his mind, any DWR coating, PFAS-free or not, doesn’t add significant value to bikepackers. As Greg put it, “Bikepacking gear is not next-to-skin and sees use and abuse differently than jackets and pants. It’s also important to note that when X-Pac wets out, it still maintains its waterproofing. X-Pac is waterproof not because of a DWR coating but because of a dedicated layer of material in its laminate makeup.”

According to Greg, most waterproof bags don’t rely on a short-lived water-repellent coating; they get waterproofness from their unique construction. However, finding PFAS-free bags as a consumer isn’t a simple task. Even fabric made from Ultra-PE, a polymer that’s naturally water-repellent and doesn’t need a DWR, is sometimes mixed with layers containing PFAS. Thankfully, eliminating PFAS seems to be on everyone’s minds right now, so most fabric manufacturers make it easy to find out if they are eliminating the use of intentionally added PFAS, a fancy way of saying, “There might still be a little PFAS floating around, but we didn’t add it.”

I had a long chat with Jon Mersereau, the sales manager of X-Pac at Dimension-Polyant, and he echoed much of what my research turned up. The new legislation surrounding PFAS in outdoor apparel and textiles is convoluted, and the specific wording and definitions leave much room for interpretation. Jon explained they want to be “as sustainable as possible,” and transitioning to a C0 (PFAS-free) coating on their fabrics helps achieve those goals. It was interesting to hear that in 2017, when Dimension-Polyant upgraded its Connecticut factory to be able to apply its own DWR coatings, the market wasn’t pushing toward eliminating PFAS. Despite C0 coatings improving significantly since then, some overseas markets still demand C6 fabrics. Moving forward, it sounds like these fabrics might still be available as a custom order to parts of the world where there aren’t laws and regulations in place. However, Jon assured me X-Pac’s C6 DWR has undetectable levels of PFAS, and they still prefer the move toward C0 DWR for the sustainable measures as well as eliminating confusion within their product line.

In the US, however, as soon as the new laws were announced in 2022, X-Pac’s customers wanted to shift as early as possible to get ahead of the change. Despite California and New York being the only states to ban the use of intentionally added PFAS in textiles and apparel, Jon explained California is a massive market for clothing and gear, so any brands that sell within the US would lose a significant customer base by not making changes. X-Pac’s European partners say there are restrictions but no laws that ban PFAS completely, yet they’re still moving toward eliminating PFAS to get ahead of future changes.

Jon agrees with Greg’s thoughts on DWR coatings not being crucial for bikepacking bags. While a DWR coating can assist, X-Pac itself is already waterproof, so those magical chemical-powered beads of water most of us associate with something being waterproof aren’t much more than a visual reminder that the fabric is doing its job, at least in the case of X-Pac used for bikepacking bags. It was also intriguing to learn that C0 X-Pac and C6 X-Pac are identical fabrics, just with different coatings. C6 uses a PFAS chemical-based DWR, while C0 uses a seemingly harmless and non-toxic wax-based coating. Performance-wise, the average consumer likely won’t notice much of a difference, but Jon didn’t go as far as saying there isn’t a performance difference. So, do we need DWR for bikepacking bags at all? Are high-quality waterproof fabrics enough?

What’s Next?

Overall, it seems we’re on the right track to begin the long process of eliminating harmful chemicals from consumer products. It won’t happen overnight, but putting pressure on brands and manufacturers helps. After all, that’s precisely why GORE-TEX ePE was developed in the first place.

While there’s a lot of troubling news from the US and around the world, one standout announcement was the Trump administration’s decision to withdraw the U.S. Environmental Protection Agency’s proposed regulations on PFAS in drinking water caused by industrial wastewater. The original regulation, rolled out in April 2024, was set to be the first-ever national, legally enforceable drinking water standard to protect communities from exposure to forever chemicals. It’s a setback, yes, but hopefully a temporary one.

Given how stubborn PFAS products are, my only recommendation would be to do your best to maintain the gear you already own instead of rushing out to replace it. After all, the damage has already been done in creating those product. When it comes time to replace your favorite waterproof jacket or buy some new bikepacking bags, take the time to find out what fabrics and technologies are being used. From what I’ve seen while researching this article, the brands open and willing to talk about their relationship with PFAS are often the same folks making big moves to eliminate them.

Want to learn more? I suggest starting with the Forever Chemicals podcast, as it details much of what I’ve shared here. I’ve included some other useful resources worth reading if you’re interested. If you have any other thoughts on PFAS in the world of bikepacking and outdoor gear, please share them in the comments below.

Additional Reading and Resources

– PFAS Exposure Linked to Thyroid Cancer

– A Chemical Shell Game: The Intercept

– Greenpeace: Detox My Fashion

– PFAS GORE-TEX Greenwashing Hagens Berman Law

Further Reading

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.