A Look Inside ORTLIEB: Made in Germany Since 1982

Share This

To help mark their 40th anniversary this year, ORTLIEB recently invited us in for an exclusive visit to their expansive facility in the southeast of Germany to see how their universally recognizable waterproof bags are made and learn more about their mission and values. Find our photographic tour of ORTLIEB HQ and an interview with some of the team here…

Co-written and co-photographed Joshua Meissner (@joshm.de)

ORTLIEB’s colorful waterproof bags are synonymous with bicycle travel, and it’s hard to think of a more iconic brand among touring cyclists. They’ve moved into the bikepacking space in more recent years, launching a number of unique and innovative bags that have earned positive reviews here on the site. As of this year, they’re celebrating four decades of making bags in Germany, and they offered us a rare look inside their factory and headquarters to coincide with that milestone.

So, at the tail end of last year, Josh and I hopped on a train from Berlin and headed south to enjoy some time pedaling across Bavaria on our way to ORTLIEB. Early the following morning, we rolled up to their campus in the sleepy town of Heilsbronn and spent a full day walking around the sprawling facility, getting to know the ins and outs of the company and seeing some of how their bags are developed, tested, and produced.

Following our visit, we caught up with our tour guides, senior PR & communications manager Peter Wöstmann and senior product manager Falko Schott, to answer some lingering questions. You can find our interview with the pair alongside a gallery of photos from inside ORTLIEB below.

Start us off by sharing ORTLIEB’s origin story. When and why was the company founded?

Peter: In 1981, Hartmut Ortlieb was a young man cycling around southern England. Anyone familiar with their weather will know that rain is the rule rather than the exception. Hartmut was irritated by his clothes and sleeping bag getting wet in his panniers. At one particularly wet point on his ride, a lorry with a tarp over its cargo to keep it dry passed him, and this inspired him to grab his mother’s sewing machine and make his first pack after returning to Germany. It was sewn and then taped over the seams to make it somewhat waterproof.

Hartmut did a lot of climbing at that time, and when his friends saw his pack, the first “orders” followed soon thereafter. Eventually, ORTLIEB GmbH was founded in early April 1982; the company HQ was in mama Ortlieb’s garage.

Which milestones would you highlight in ORTLIEB’s 40-year history?

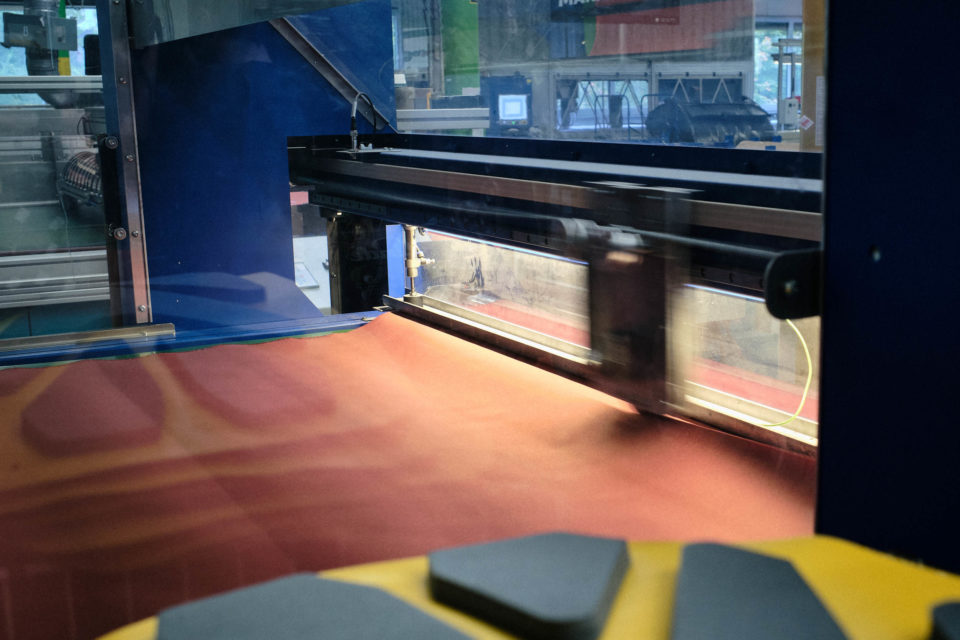

Falko: Hartmut was self-taught in the technique of high-frequency welding, and the first bag he welded was the Back-Packer. Today’s most iconic pannier, the Back-Roller, followed in 1987 with the first stuff sacks. In 1994, the self-locking mounting system for panniers, the Quick-Lock1, came onto the market.

As the company had outgrown the manufacturing space, its then-60-or-so employees moved to Heilsbronn in 1997. Soon after, we founded ORTLIEB USA. Then the Quick-Lock2 pannier mounting system came into use just before the turn of the millennium.

In recent years, our noteworthy events are definitely the entry into bikepacking, the first waterproof bike basket, and the Atrack, the first waterproof hybrid of backpack and travel bag.

ORTLIEB has been on top of the bike bag business for several decades now. To what do you attribute the company’s success on that journey?

Falko: ORTLIEB has always stayed true to our core philosophies. Being a German manufacturer allows us to be unconventional and innovative, with a constant eye on new trends. Product development is still spearheaded by Hartmut Ortlieb, who’s never been satisfied with the status quo.

That said, more than any technical aspect, ORTLIEB’s success as a brand is a result of the people using our products around the world and the stories they tell about the durability and dependability of any bag bearing the ORTLIEB name.

Tell us a little about your space in Heilsbronn. How big is the facility, how many people are working there, and what kind of roles are they in?

Peter: Our HQ in Heilsbronn, about 20 miles west of Nuremberg, has been expanded several times in the last 20 years, and it’s now about 160,000 square feet (15000 m²). ORTLIEB only has this one campus, with the exception of ORTLIEB USA, which is a subsidiary.

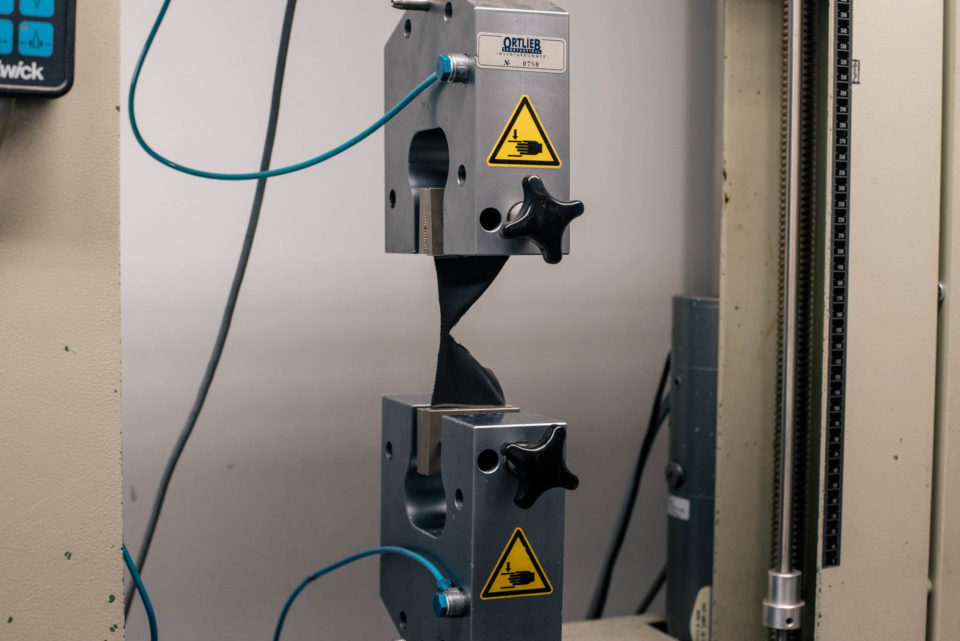

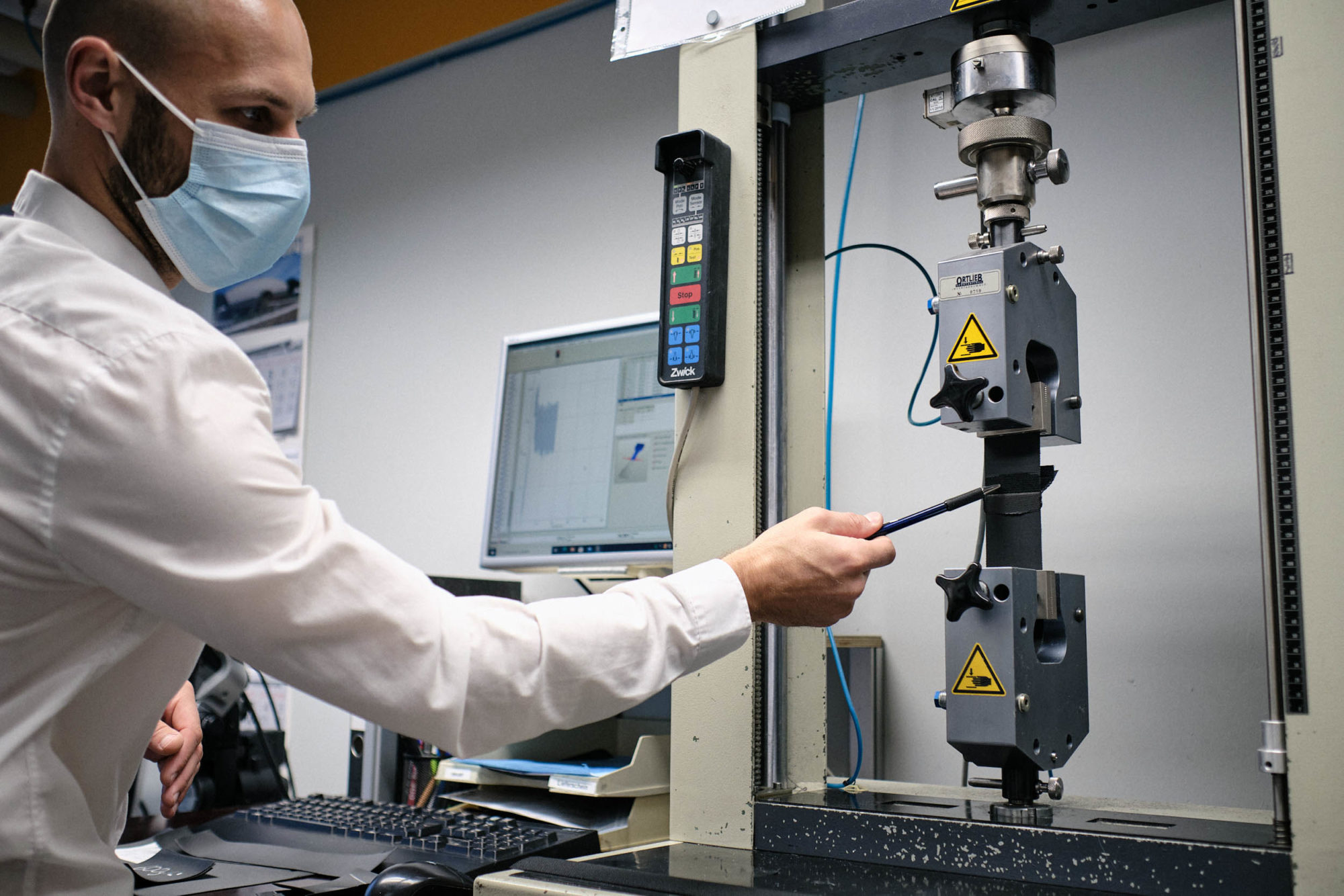

With about 300 employees and growing, almost everything takes place in Heilsbronn: design and construction of our production machinery, product manufacturing, industrial design, R&D, materials and product testing, product management, and prototyping. It all takes place on-site.

ORTLIEB invented and perfected welding waterproof bike bags, but the process isn’t unique in the cycling arena anymore. What’s your next move to stay ahead of the competition?

Falko: We remain dedicated to Hartmut Ortlieb’s drive to create functional solutions for all types of people. Yes, we have 40 years of experience creating RF-welded, waterproof bags, but we’re also constructing our own tooling and doing all in-house production. As mentioned, we believe this results in unrivaled quality.

Additionally, we file numerous patents every year as we continue to innovate our end products. The latest example of our innovative evolution is the Vario PS. This is a great instance of a seemingly simple solution that’s packed with innovative design and new techniques created right here at ORTLIEB.

Why produce in Germany? What do you see as the unique advantages and disadvantages of doing so?

Peter: ORTLIEB stands for waterproof, durable outdoor equipment. “Made in Germany” is our brand promise for high-quality gear, local employment, environmentally friendly production, and innovation. Right around 90% of all processes are located in-house at ORTLIEB, and the goal is to increase this so everything can be continuously optimized and guaranteed to be done in the most environmentally friendly way while supporting a high standard of employment conditions for the whole ORTLIEB team.

One obvious drawback, of course, is the comparatively high wage and energy costs. However, approximately 30% of our energy for production comes from solar panels on the roof, and we’re working toward relying exclusively on our own renewable energy.

What does “Made in Germany” really mean?

Falko: More than 70% of the raw materials come from Germany. All injection-molded plastic parts on our products, for example, are made just around the corner. The fabrics for our products come from the region as well, and we buy waterproof TIZIP® zippers from Hartmut Ortlieb’s second company, which is in the building next door. This allows us to guarantee shorter transport routes, a more transparent supply chain, lower emissions, and faster delivery times.

As Peter mentioned, 90% of all production processes are in-house in Heilsbronn. As a result, sustainability has always been part of the ORTLIEB DNA.

For materials sourced outside of Germany, how close are your relationships with your suppliers, and what does ORTLIEB look for in its partners along the supply chain?

Falko: With all of ORTLIEB’s sourcing, the guiding principle is to look regionally, then nationally, then throughout Europe, and only then do we finally look globally. We strive to maintain long-term partnerships with our suppliers, and we insist on them being transparent with their practices.

ORTLIEB gear has a reputation for being durable. But, what happens if a bag fails, potentially many years after purchase? How do you take care of repairs?

Peter: We’ve always created products that are durable but also repairable. With our team in Heilsbronn, we can handle repairs and upgrades – so if a customer wants to update the attachments on some older Back-Rollers, we can make those changes for them. Many specialty retailers, as well as distribution partners in various countries, have been trained to carry out repairs locally too. We are continuously working on expanding this service network. The opportunities for a local repair reduce long waiting times for the customers and saves having to ship products by parcel all over the world.

All the individual parts of our products are designed and constructed so that they can be replaced. Even after years of intensive use, our service team can fix small holes by welding in new fabric patches. In that light, ORTLIEB achieves an even longer service life for an individual product, which of course, is the most sustainable approach for anything.

In addition to our standard five-year warranty against defects, it’s worth noting that we guarantee the availability of spare parts for at least ten years after an item has been dropped from the collection.

Producing hardwearing waterproof fabrics comes with an undeniable environmental cost. What are you doing to reduce the environmental impact of your products and operations?

Falko: Firstly, we have always opted for high-quality and long-lasting materials for our bags to ensure that our products rarely have to be replaced and fewer of them end up in a landfill. Second, we source fabrics from countries and factories where environmental laws are enforced and workers’ rights and safety are ensured. Finally, since we are the factory, we always know where our raw materials come from, protecting our product integrity at all levels.

ORTLIEB’s waterproof brightly colored panniers are instantly recognizable and can be found on bikes all over the world, but how are the newer bikepacking bags catching on, and how much of your focus is on bikepacking these days?

Falko: We launched our bikepacking collection in 2016, which coincided with the start of the gravel bike and bikepacking boom in Europe. The global demand is tremendous, and bikepacking has become a significant category for ORTLIEB all over the world, but not one that we need to concentrate on exclusively. Alongside our classic touring and bikepacking ranges, we also have outdoor equipment, backpacks, and bags for urban use, as well as expedition and travel packs.

The all-black look of your bikepacking bags is quite a departure from what we’d typically expect from Ortlieb. Is this purely an aesthetic choice or is there something unique about the black material used to build them?

Falko: The combination of the black PU-coated nylon fabrics and orange accents (our company’s signature color) was an aesthetic decision at first, but it just so happened that we had two new materials that turned out to be light and highly durable. Perfect for bikepacking. And who knows, perhaps the future will also see a different colorway. Maybe as a limited edition?

Most bag manufacturers offer frame bags in multiple sizes and even different shapes to account for various bodies and bike geometries, but ORTLIEB only makes them in one or two sizes for most models. What’s keeping you from offering more sizes?

Falko: Unfortunately, the production requirements for RF-welding in many shapes and sizes is a limiting factor here. It comes down to making bags for the most popular sizes in the market. Of course, we do regret not being able to offer frame bags suitable for some very small frame sizes.

How do you keep up the steady stream of ideas for innovative products? Can you share anything about your product development cycle?

Falko: With bikepacking, for example, our team at ORTLIEB USA introduced the topic to the German product team in 2014. We worked on the project from that moment on, and in 2015, the first samples were ready and underwent testing. The new line was premiered as part of Sea Otter Classic 2016.

However, not every product has such a long R&D period. The Bikepacking line was a complete collection, after all. The Fork-Pack originated from a little “secret mission” by our head designer. The first prototypes took three weeks. Even still, it took about 18 months from concept to launch. The development of the patented mounting system, QLS, added time to the process.

Right now, our product and R&D teams are working on the projects for 2024, and the projects for 2025 have already been laid out.

What’s a product in your bikepacking line you’re particularly proud of and why?

Peter: The Handlebar-Pack QR and the Bar-Lock fastening system that accompanies it are key innovations thanks to the simple attachment that creates an extremely-stable interface with the handlebars. Further, it closes the gap between bikepacking and daily bike travel.

Switching gears, how’s the riding around Heilsbronn, and is it a good testing ground for new products?

Peter: Heilsbronn is in a rural area, so the riding outside of town is lovely. And Lake Altmühlsee and Lake Brombachsee aren’t too far south. On the way, there are some good hostels offering some tasty Bavarian food and drink. So, it’s a perfect tour for the summer.

For more MTB-oriented rides, turn towards the east and you’ll find the hills known as the Franconian Switzerland region (of Germany). Along with the solitude of the countryside, the area offers demanding trails, and this terrain continues all the way to the route for the Grenzsteintrophy bikepacking race along the former inner German border.

Any upcoming products you can tease?

Falko: The current new products such as the Seat-Pack QR and Vario PS are worth checking out. There’s also the new Quick Rack or Quick Rack light, and we’re working all out to make these products available for the US market in 2023.

Lastly, what else should readers know about ORTLIEB?

Peter: We’re in this for the long haul. Waterproof bags aren’t just an accessory line for us: they’re what we do and what we’re passionate about. We’re consistently growing, too, and we’re always looking for good people to join the team!

40 Years of ORTLIEB Video

For a further look at ORTLIEB, don’t miss this endearing three-minute video that introduces some of their cast of characters, speaks to the brand’s ethos after 40 years, and provides additional views inside and outside their space.

Related Content

Make sure to dig into these related articles for more Field Trips...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.