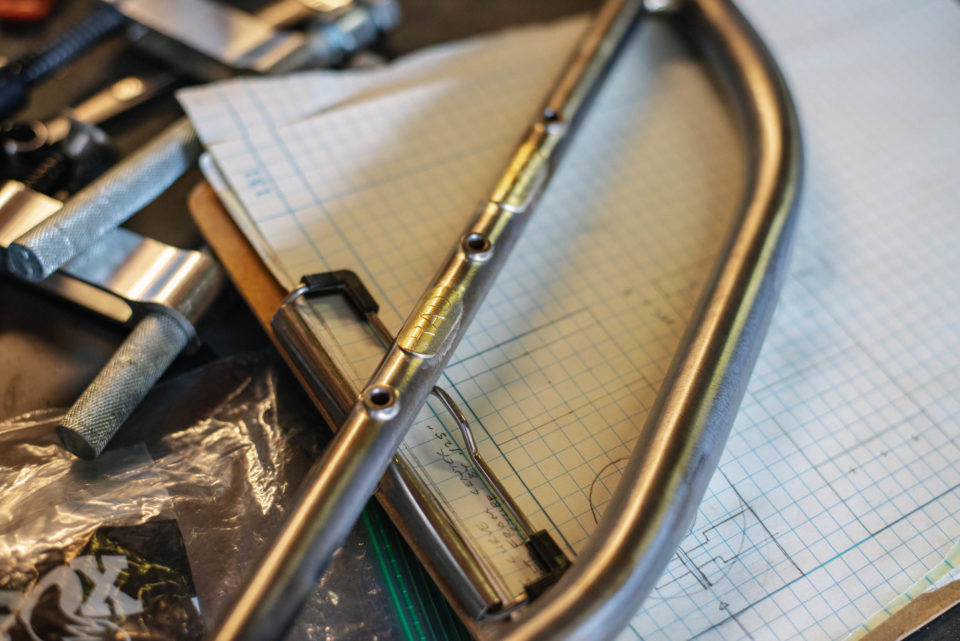

A Bite-sized Look at Lunch Break Brazing in Minneapolis, MN

Share This

Intrigued by the beautiful handlebars and other metal creations he’d glimpsed on Instagram, Lucas recently stopped by the garage workshop of Lunch Break Brazing in Minneapolis, Minnesota, to meet maker Wes Kuhnley. Find a photo tour of his space, some insight on the downsides of commodifying your hobbies, and a peek at some of his current lunchtime passion projects here…

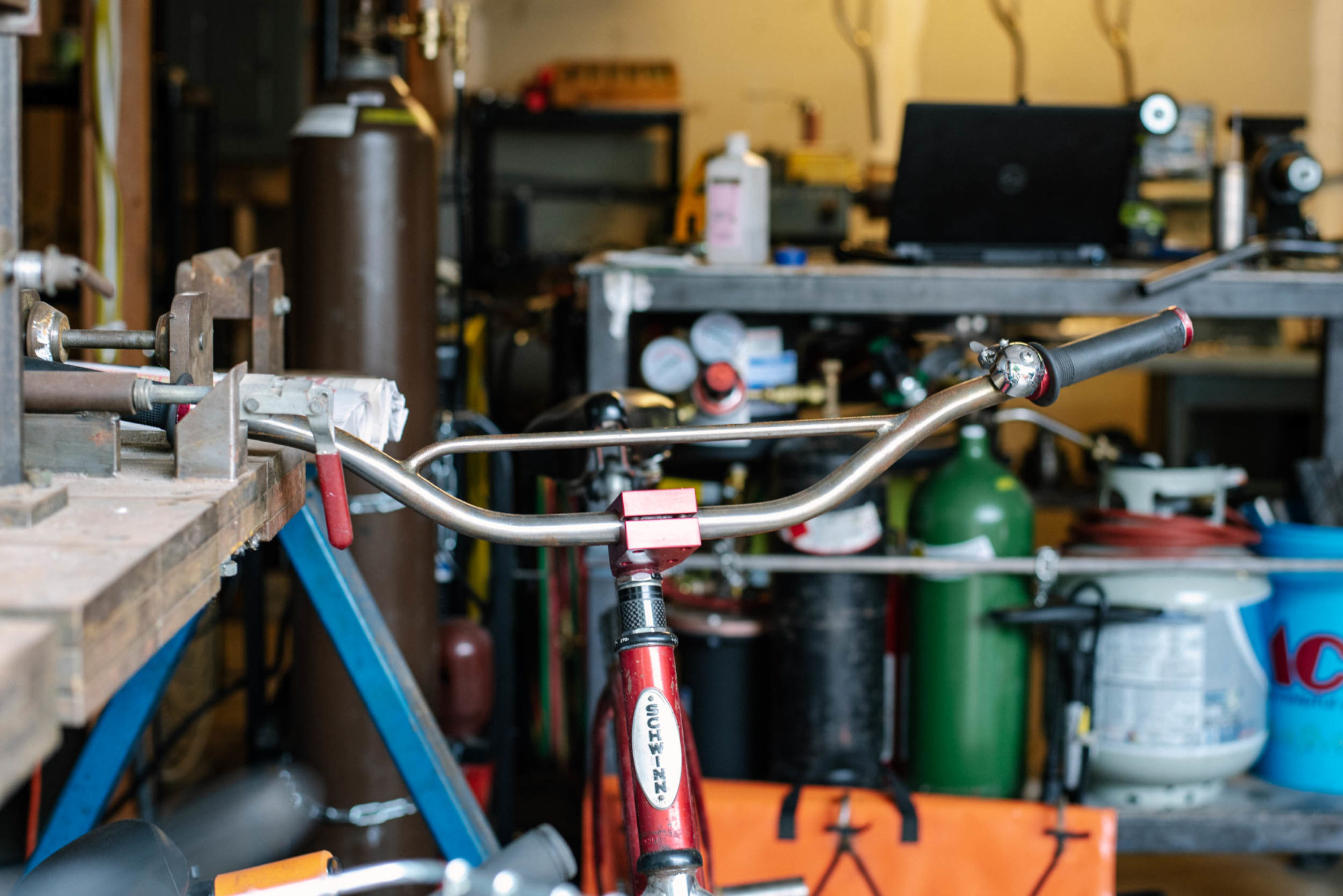

One day while visiting Minneapolis this summer, I was working from a coffee shop when I stumbled upon the Instagram account of Wes Kuhnley of Lunch Break Brazing (@lunch_break_brazing), a hobbyist who’s been busy making and documenting a wide variety of interesting metal projects—mostly handlebars—during his off hours. As it turned out, his garage workshop was just a few blocks away from where I was sitting with my laptop. I sent Wes a message, and he agreed to have me over for a few hours so I could learn more about his work and what he’s up to.

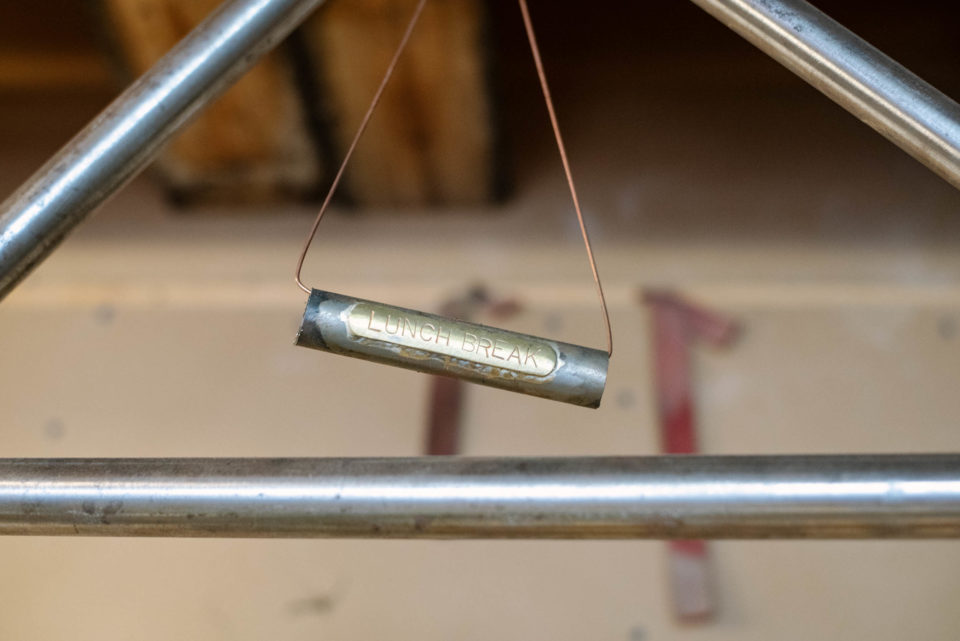

Truth be told, I went there expecting to meet someone eager to ride the wave of a growing Instagram following to sell products, but it soon became apparent that passion and a love of learning are the driving forces behind his lunchtime project. As he worked on fabricating a trailer to haul his kids behind his cargo bike, Wes told me about how he got started and what keeps him excited to continue tinkering and creating more than two years after making the first handlebars under the Lunch Break Brazing name, which he raffled off to benefit local minority-owned businesses in the wake of George Floyd’s death and the onset of COVID-19 lockdowns in 2020. You can find my brief interview with Wes and a photo tour of his workspace below.

Start by telling us a bit about yourself and your background.

Vocationally, I’m an engineer, although I do less day-to-day engineering these days and am primarily involved in leading engineers in product development. Long story short, I started my career in the music industry, where I owned a small business, but I got totally burned out in that industry over 10 years, and then joined the corporate medical device world. Turns out that paid vacation is a beautiful thing. When I’m not at work, I’m a dad to two awesome kids, a husband, a single-speed cyclocross evangelist, and an enthusiast in all things math and physics.

When and how did Lunch Break Brazing come to be?

A few years ago, my wife sent me to a welding class here in South Minneapolis. They taught a one-night crash course, mainly in MIG welding, but also how an Oxy-Acetylene torch works and some other things. I ended up doing just a little brazing that night. I picked up a torch setup a while later, watched about 1,000 YouTube videos in hopes of not blowing myself up, annoyed the guys at the welding supply store a bit, and then just started trying to make stuff.

I’d discovered Cjell Mone on Instagram not long before and fell in love with his work, his bikes, and everything. So, I decided I’d teach myself to do that. I feel like I’m getting pretty good at it now, but I’m still nowhere even close to his level of work—not to mention many other fantastic builders who inspire me. They’re absolute experts; I’m a guy in a garage, goofing around on his lunch break. That’s where the name came from: I was starting to annoy friends and family with all the metal-related content on my regular Instagram account, so I made a new one just for these projects.

Tell us about one of your favorite projects/products to date.

If I had to pick, it would be the “Nature Boi Zona” clone I built for myself. All-City never made a Zona in my size, and the Fulton Racing livery bikes from that era are unobtainium, even if they did. Making a bike frame was a stretch goal when I started off, and although it’s not perfect, I’m very proud of it.

I have to mention that Paul Brodie’s YouTube series is essential watching for anyone trying to figure out how to go about making a frame. I’m so excited to race on that bike next year.Aside from that, I guess my favorite projects are the ones that make me figure out something new, and then when I’m done, someone else gets pumped about how it turned out. I had a great reception to a recent batch of riser handlebars I made, and I enjoyed designing a process to make a bunch of them rather than just one.

From visiting your space, it’s clear that you love to tinker. Beyond brazing, what other hobbies keep you busy?

I’ve had a couple of knee injuries over the last two years that have limited my time on a bike, but once those are behind me, I’ll be back riding more often. I love single-speed cyclocross racing, mountain biking, klunkers, and bikepacking. I’m really looking forward to taking my kids bikepacking more next spring and summer with the cargo bike and trailer project I just finished. I’d love to get better at building wheels too.

As for non-bike-world stuff: I’m always trying (and failing spectacularly, just ask my family) to master hashbrowns, and my kids, brother, and I are working on rebuilding a 1978 Honda Civic that someone transformed into a truck in the early 90s. The truck even has its own Instagram (@78_civic_truck).

When we met, you mentioned that Lunch Break Brazing is more of a passion project than a fledgling business venture. Can you share a little about your thinking and how you maintain that balance?

My time in the music industry is the primary factor here. It’s really easy for a maker to create a widget or two, get a good response from their friends, and quickly get seduced into trying their hand at selling them as a business. This then implies all kinds of new things you have to care/think about in order to start making that business sustainable or “worthwhile.” Material cost, labor, pricing, taxes, marketing, the list goes on forever. That shit just stresses me out and takes the fun out of it.

There is a vast chasm between the crafting of the widget and running a sustainable business making widgets. For me, spending time in the shop learning things is what’s worthwhile, and that’s the way I want to keep it. So yeah, it’s technically a business, and I do sell some things, but those are only ever things I’m currently pumped about, and they’re only made while I’m having fun doing it. The project is always the center of my attention, not the selling of the thing at the end, if that makes sense. As a business, it’s a terrible model, but it stays fun that way.

If you had unlimited time and resources, what’s the first thing you’d make?

I’m not really sure! If I had more garage space, I might try to build an electric car. Once I’m confident enough in my TIG welding to weld a tubular frame, anyway. There are so many options and ideas; I have no idea which one I’d choose to pursue.

Are you currently selling any products or merch? If not, do you have any plans to make either available?

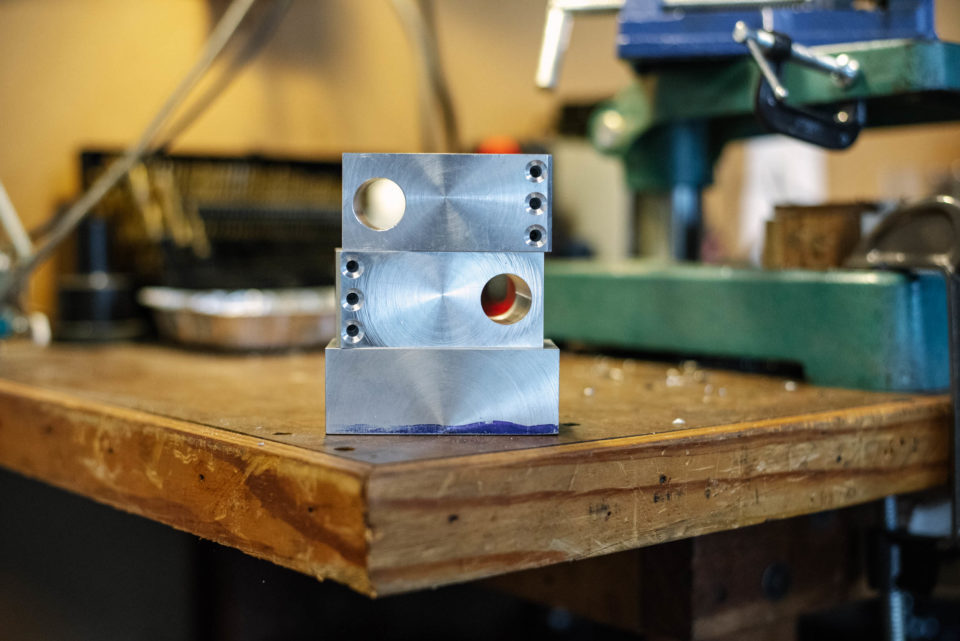

As far as products, I usually start tinkering with a project and announce it on Instagram. Currently, that’s a batch of BMX stems I’m making on the lathe. There will be more bars in process as we get closer to spring 2023. In terms of merch, my friend Paul drew Iggy the BLT, who has sort of become my adopted logo. We’ve tossed around ideas for making T-shirts or stickers or something, but it’s not very high on my priority list. I think it would be funny to have Iggy saying something irreverent and rascally, but I haven’t gone any further than that basic idea. He’s such a cheerful-looking sandwich. He’s gotta have a dark side, right? Like Ralph Wiggum, but you’re wondering if he’s up to no good.

Lastly, any exciting new stuff in the works that we can look forward to?

Yeah, I’m currently working on a few things other than the small batch of BMX stems, and I’m pretty excited for people to see them. I’m working on two stainless racks for friends, a couple of jigs for brazing stems and bike frames, and ever so slowly teaching myself to TIG weld. My ultimate goal there is titanium. I think it would be super sick to make a batch of Ti riser or Bullmoose bars, but I have a way to go before I’m confident enough to do that. Always something new to learn!

The best way keep up with Wes and Lunch Break Brazing is by following him on Instagram @lunch_break_brazing.

Related Content

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.