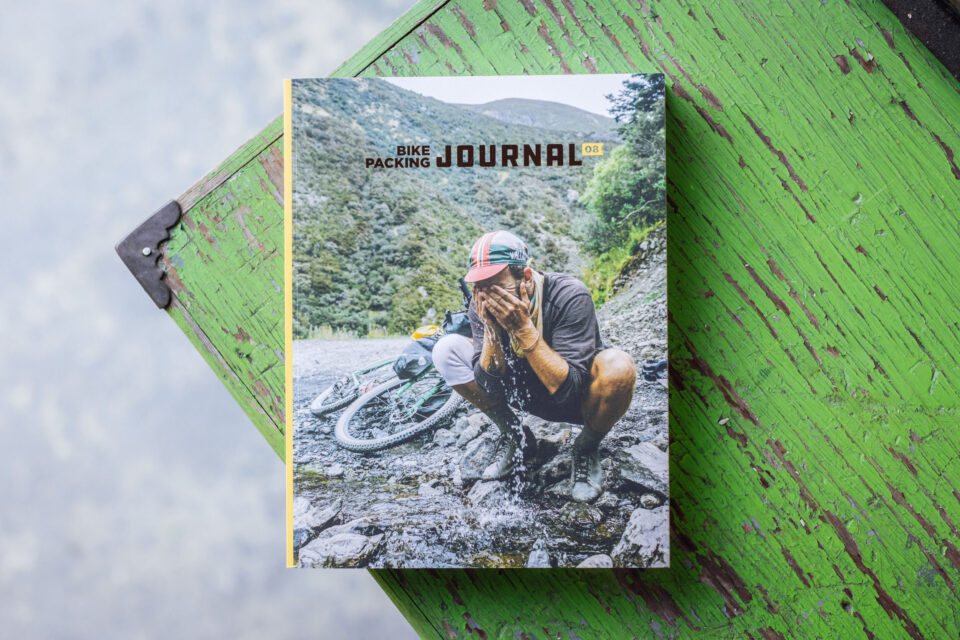

Porcelain Rocket “Albert”: Introducing the First Dropper-post Seat Pack

Building on the concept behind their popular Mr Fusion, Porcelain Rocket has been working on a new seat pack, one that’s dropper-post compatible — called “Albert”. Find out how it got its name and get a unique look into its long design process – trials that involved endless brainstorming, seven prototypes, and months on the trail – and at the production version, coming this fall…

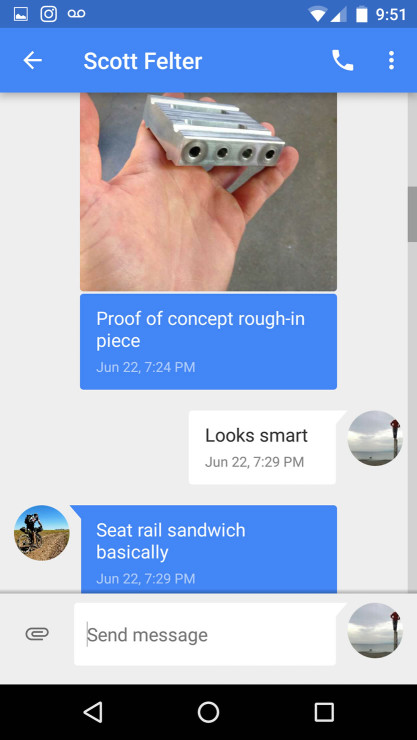

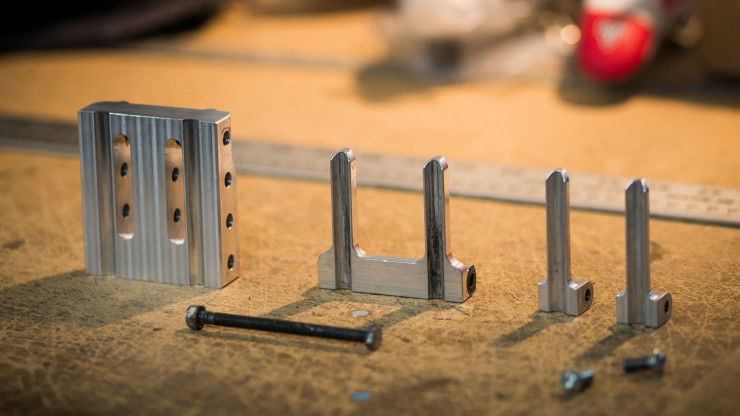

In late June of this year, Scott Felter, the owner of Porcelain Rocket in Calgary, sent us a photo of a radically curved Mr Fusion seat pack rack and an aluminum block with several holes and grooves machined in it.

“Looks smart” I said, not really understanding what I was looking at. These were the first whisperings we’d heard about a dropper seatpost-compatible seat pack. The function of the rack was intuitive: by curving the support rack upward toward the seat, it could mount in a way that would allow a seat post to drop unimpinged by the clamp. But the block was a still a real mystery to me at this stage.

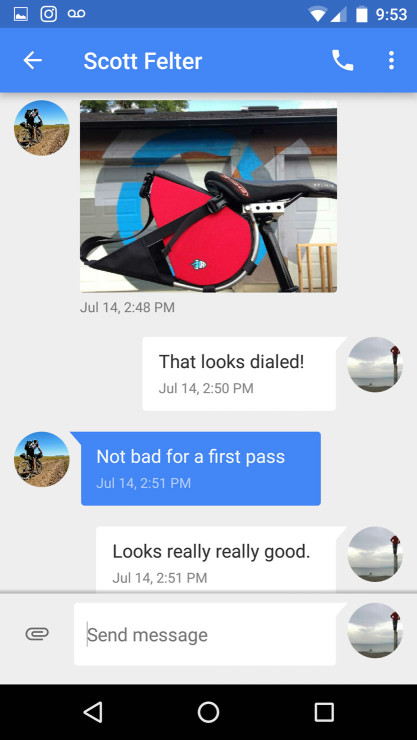

Weeks later, I received another photo: this time, the rack and block were installed on a seat post. But still, I didn’t quite understand how it attached. What was clear was that there was no clamp around the seatpost at all. Therein lies one of the most brilliant elements of Scott’s design.

The aluminum block, rather than clamping around some part of the seat tube, fits between the bottom of the seat rails and the seat clamp. Since the mounting point is effectively a shim between saddle rails and seatpost, it can safely be used with any saddle – including those with carbon rails – and most seat posts. Of course, subsequent versions of the (patent pending) mounting shim have been sleeker and more elegant than that early proof of concept. The production version splits the mount in two, using a small mount shim under each saddle rail, which will ensure a good fit regardless of small differences in seat post clamp dimensions, and allows the mount to slide further forward on most seat posts.

My own involvement in the design process didn’t start until I finally realized what I was looking at, and how the mounting shim functioned. With my mind thoroughly blown by the ingenuity of it, I set to bombarding Scott with my notion of what might be the design constraints and objectives. Naturally, having had this on his mind for months, he was way ahead of my every thought. Nonetheless, it seems my enthusiasm counted for something, since I was eventually offered the chance to test what was at that time the only prototype for two weeks on the Colorado Trail. But that comes later.

As with each iteration of the Mr Fusion seat pack, Albert’s metal pieces are made outside of Porcelain Rocket’s small Calgary shop. The chromoly rack component is built by Rick Hunter of Hunter Cycles in California, while the machined aluminum shims (and clamps on Mr Fusion) are made in a Calgary machine shop. The latter gets most of its business building custom components for Alberta’s oil and gas industry, where transactions usually start in the five-figure range, and multi-million dollar projects are not unheard of. Small one-off prototype items do not come cheap. The production version — of just the mounting shim alone — reflects a research and development cost of several thousand dollars, while the hardware for the first prototype made it surely among the most expensive seat packs to ever exist.

Scott spent the month of August testing “Albert I” while bikepacking in Newfoundland. While he did not use a dropper, he succeeded in proving the viability of the general concept. A few design constraints came to light in this first prototype: first, side-release buckles were incorporated into each of the load-bearing side straps, just like on the Mr Fusion, and on Albert much higher force is placed on these side straps. Whether on Mr Fusion or Albert, the lateral forces (or “sway”) are taken care of by the rack – that lateral stability is what makes these seat packs some of the best available. But, the rack does not entirely eliminate vertical movement in the seat pack. Rather, the mounting bolts (at the clamp on Mr Fusion, and at the shim mounts on Albert) act as pivot around which the seat pack can rotate up and down. But, more so than on the Mr Fusion, Albert’s mount-point pivot is much closer to the back of the seat rails, where the side straps are anchored. As such, the weight of the seat pack is acting on a relatively longer lever, increasing the forces on the side straps.

Over one particularly hard impact, one of the side buckles on Scott’s early prototype exploded, and just like the namesake Albert I – the first primate to not-quite-make-it to space, who lasted only moments when the inside of his spacecraft depressurized – the seat pack met a catastrophic demise as it rotated into a spinning wheel.

It’s worth noting that the damage was much less severe than that makes it sound – the rack and mount were unharmed, and the damage was entirely field-repairable.

Though it was clear that the buckles were (a) a weak point and (b) not necessary, after Scott’s trip to Newfoundland, this element of the design didn’t actually change in round two. Rather, the changes made to the design that I’d test on the Colorado Trail, in September, reflected the fact that Scott’s first prototype was very difficult to construct. To address this, some small changes were made to how the side panels connect to the rack. Since the buckles hadn’t yet changed, Scott advised me to close the side-lock buckles with zip ties for insurance.

Unfortunately, Albert II the seat pack fared only a little better than Albert II the space monkey, who really did make it to outer space, but met his demise at terminal velocity when his spacecraft’s parachutes failed to deploy. (The Wikipedia article about monkeys in space reads as a heart-wrenching tragedy…) Alas, the thin loops used to lace the side panels onto the chromoly rack needed to withstand higher forces than expected and they began to pull out of the seam. This however made it clear that the connection between side panels and rack stays was structurally important. As the lace-loops pulled out and the connection loosened, I found the vertical bounce of the seat pack became more and more severe. Initially, I’d been dropping my saddle about 110mm (leaving only 60-70mm between seat pack and tire), but in its semi-broken state it would buzz against the tire on bigger hits if I lowered it more than about 50mm. On descents, I was stopping every couple of minutes to tighten the side straps which would slip after so much bouncing.

Scott later admitted that he didn’t have a lot of confidence in the version I tested in Colorado. He was just sort of hoping that it would be sufficient. After all, it was sent my way on relatively short notice, and much of it was recycled from his own Newfoundland prototype. But still, this experience pinpointed the importance of the connection between the plastic-stiffened side panels and the rack rails.

My eventual field repair, after four days on the trail, worked by lacing the side panels together and around the rack through holes that I’d melted in the side panels’ plastic stiffener using a cook stove and a hot metal rod. The laces would loosen over time, with any slack working its way toward the bottom where the tension from the side straps was directed, and the vertical bounce would slowly increase. Still, by occasionally tightening the lace over the next ten days, the seat pack remained stable with a manageable amount of bounce. I was able to continue dropping my saddle – safely down by 80mm or so with the occasional tire buzz if I went a bit lower, leaving a bit more than 3” between the seat pack and tire.

These two weeks in Colorado — the first time Albert had been used on a bikepacking trip in conjunction with a dropper post — also proved that Scott was on a righteous path. In short, bikepacking with a dropper post was completely revolutionary. Never had I moved so efficiently and enjoyed challenging riding on a loaded bike to that degree. The benefits of riding with a dropper seatpost on day rides on technical mountain bike trails are multiplied many times when riding long days, day after day, on a bikepacking trip. Having experienced it, I can’t imagine riding something like the Colorado Trail without. It can’t be overstated how life-changing this was, and it solidified my own commitment to the project.

A few weeks later, back home in Canada, I made a trip to Calgary to meet the guys at Porcelain Rocket and work with Scott of finalizing the design for Albert. Our first inspiration was to experiment with the use of Voile ski straps – those rubbery straps used for so much more than holding skis together – in lieu of nylon webbing side straps. The thought here was that Voile straps, once tightened and anchored at the buckle, cannot slip. It was immediately clear, however, that any amount of stretch in the side straps allowed for too much vertical bounce. Like Albert III the space monkey, this one didn’t even make out of the troposphere (or in this case, the workshop).

To resolve the issue, we decided that more robust nylon-webbing side straps, under higher tension would be the answer. By looping the strap from the rack, up to a plastic loop near the seat rails and back to a ‘tensionlock’ buckle, it acts as a 2:1 pulley system, cutting the stretch in half and doubling how tight one can get those side straps. A forward pointing pull-strap ending in a finger loop makes it even easier to get the side straps tight.

Back-alley tests had me dropping the pack to within 30mm of the tire and bunny-hopping aggressively with very little tire rub. With the merit of the “trucker hitch” side straps — as Scott likes to call it — proven , we set to improving the connection between the side panels and rack. In short order we tried several options: small Hypalon loop? Annoying to assemble. A single 500D cordura sleeve? Better, but it was bulky and still difficult to install the rack. A pair of 300D sleeves finished with ribboning? Very nice. The inner seam is double-stitched and the load widely distributed across the seam, insuring a much more resilient anchor for the side panels.

Now, back in the alley, I struggled to get the seat pack to touch the tire, even with only 30mm of clearance. Of course, I’d never recommend dropping the bag low enough to intentionally make it rub. The final product will come with guidelines suggesting to keep at least 50mm of clearance between the bottom of the pack and the tire, but the production pack is about 12mm smaller than the prototypes so this will be that much easier.

Long-legged people will always be able to drop their saddles more than the short-legged. Shorter individuals hoping to ride large-wheeled bikes, like high volume 29er tires, might have insufficient clearance for any amount of saddle drop. Tangentially, those riding bikes with very little seatpost exposed, who have lacked the minimum 6” (15cm) of exposed seatpost required to use a Mr Fusion, may be interested in using the Albert in its place. The minimum clearance for Albert to work will be communicated on the Porcelain Rocket webstore so that there will be no surprises.

The production version of Albert will look very similar to the final prototype that appears in these photos. I brought this one back to Vancouver for a bit more testing on rough North Shore trails. While rattling down the hill, the mounting bolts kept loosening from the threaded shim. In an effort to make them stay put, I over-tightened the mounting bolts and, by torqueing on them like a ham-fisted fool, I managed to bend one of the shim mounts. To address this issue, the production mount shims will not be threaded. A thru-bolt and a nylock nut will be used instead, so it will not be able to rattle loose. This will also greatly reduce the opportunity for anyone to push and twist on the mount like I did using a multi-tool. Note that the forces from the seat pack’s movement are comparatively tiny and almost entirely directed on the side straps, so the 7075 aluminum mounting shims are in no danger of bending under normal use.

The first batch of Albert seat packs is expected to be available on www.porcelainrocket.com by mid-December, and will cost $230CAD (about $170USD with today’s exchange).

- Max Volume 9 Liters

- Weight 450g complete, including all hardware, and drybag

- Price $230CAD

- Availability Mid-December, 2016

- Contact porcelainrocket.com

P.S. There were no monkeys harmed in the making of this product. – Skyler

FILED IN (CATEGORIES & TAGS)

Bikepacking Gear

Bikepacking Bags

bikepacking-seat-packs full-supension-bikepacking porcelain-rocketPlease keep the conversation civil, constructive, and inclusive, or your comment will be removed.