Just announced, the new made-in-Canada Project321 G3 hub offers 288 points of engagement, a revamped axle and bearing design, and the clever patent-pending “6-Lock” mechanism that allows you to mount a 6-bolt or centerlock rotor. Find details here…

We’ve been interested in Project321 ever since hearing about their G2 hub a few years ago. In summary, Project321 was founded in California in 2017 and developed the M-Pulse hub tech for Stan’s NoTubes’ wheels. The company later released their own G2 hub, which gained some momentum, and then announced plans last year to move to Canada and begin production on an improved G3 hub in Mississauga, Ontario. Today, the Canadian company launched its made-in-Canada Project321 G3 hub and new patent-pending 6-Lock technology.

Project321 G3 ENGAGEMENT

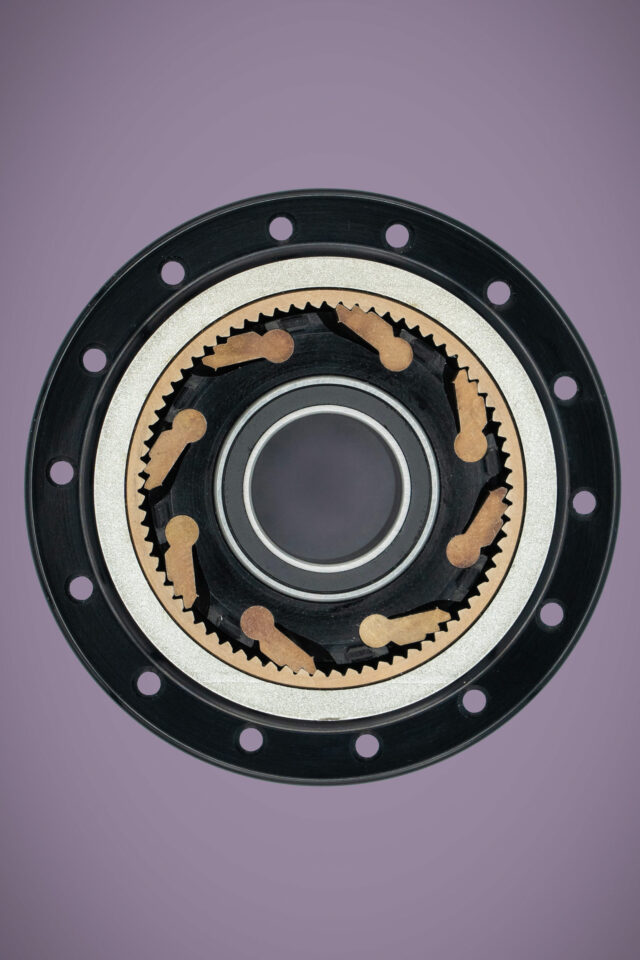

The G3 hubs employ the same 72-tooth drive ring and three-step magnetically actuated pawls as their established G2 hubs—engineered to minimize drag during coasting. Looking to boost engagement and not compromise reliability, Project321 opted to incorporate two additional pawls into G3 instead of reducing the size of the teeth on the drive ring and pawls. With a total of eight pawls operating in pairs, the G3 delivers 1.25° or 288 points of engagement. The company claims this finds a nice middle ground between immediate engagement and robust reliability. For reference, the I9 Hydra hubs we tested offer 0.52° engagement and 690 points of engagement, and the DT350 with the upgraded (and plenty quick) 54t ratchet has 6.7° of engagement.

6-LOCK

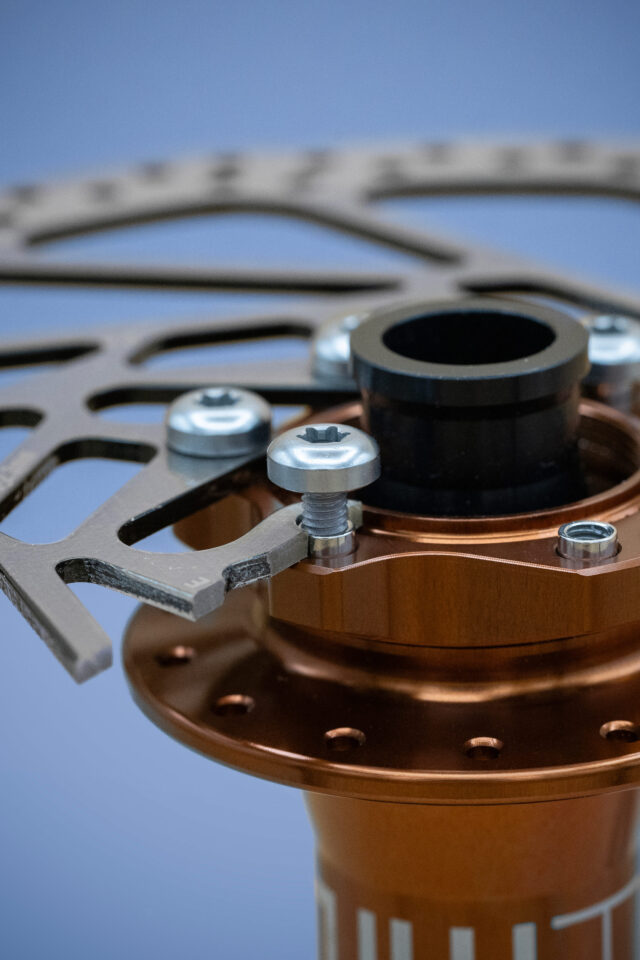

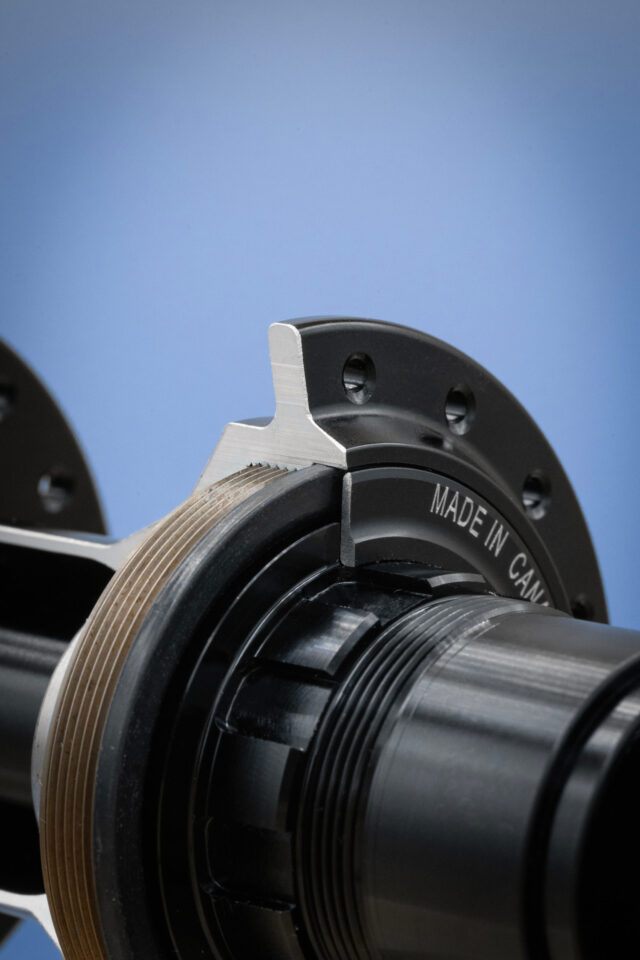

With the G3, Project321 also introduced 6-Lock, an interesting new patent-pending technology that allows six-bolt rotors to be mounted with T25 Torx screws without the need for a lockring. 6-Lock features stainless steel bolt threads and offers the flexibility to seamlessly transition to centerlock rotors anytime.

The 6-Lock system uses a stainless steel collet that locks into the channel behind the splines on a center lock brake mount. Project321 claims that stainless steel threads minimizes the risk of stripping and significantly enhances bolt retention. A 7075 aluminum flange fits over the collet to support it while locking onto the center lock splines, which Project321 says delivers a robust brake mount interface compatible with any six-bolt rotor. The system’s modular design also adds an extra layer of redundancy.

AXLE AND BEARING LAYOUT AND SEALS

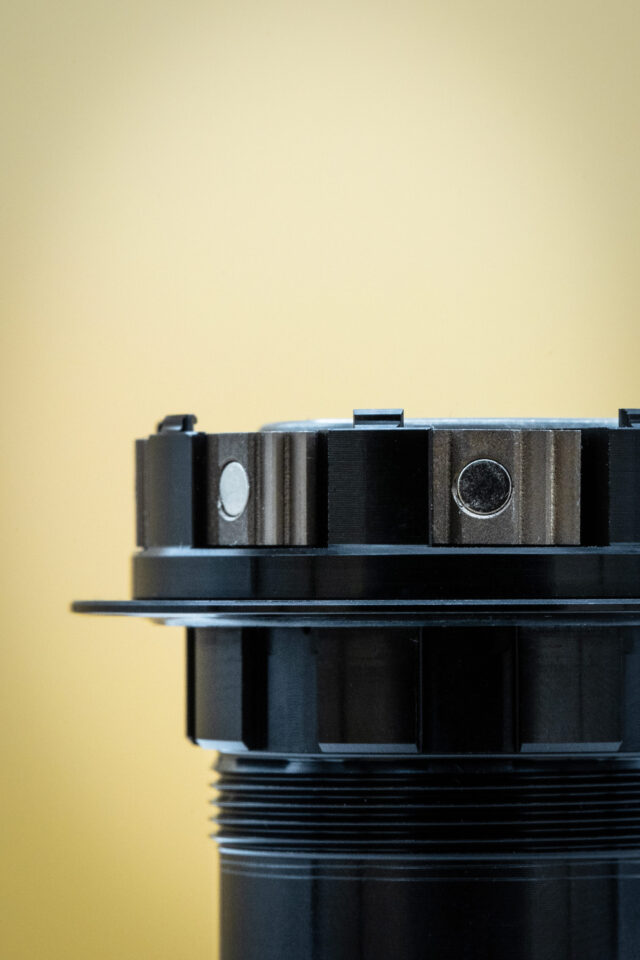

Project321 also revamped the internal architecture of their hubs, resulting in a completely redesigned axle and bearing layout. The new design incorporates two double-row bearings strategically positioned to enhance support at the 7075 aluminum axle’s most stress-prone area, aiming to eliminate issues with broken axles. Additionally, Project321 has retained preload adjustment functionality on their rear hubs. Demonstrating confidence in their axle design, which has also been integrated into Stan’s M-Pulse hubs since the beginning of 2022, the company is offering a 10-year warranty on these components.

The new seals in the G3 hubs were codeveloped with Stan’s NoTubes during the development of Stan’s M-Pulse hubs. The system is comprised of a low-drag light-contact rubber seal that is pressed into the hubshell, and an aluminum dust shield pressed onto the driver body.

G3 hubs are available in 12 colors, and there is option to mix and match end-caps and 6-lock brake flange colors. Prices start at $650 USD for a pair or $440 for the rear hub. Find more details over at Project321.com

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.