Inside Buckhorn Bags: Chasing Curiosities

Share This

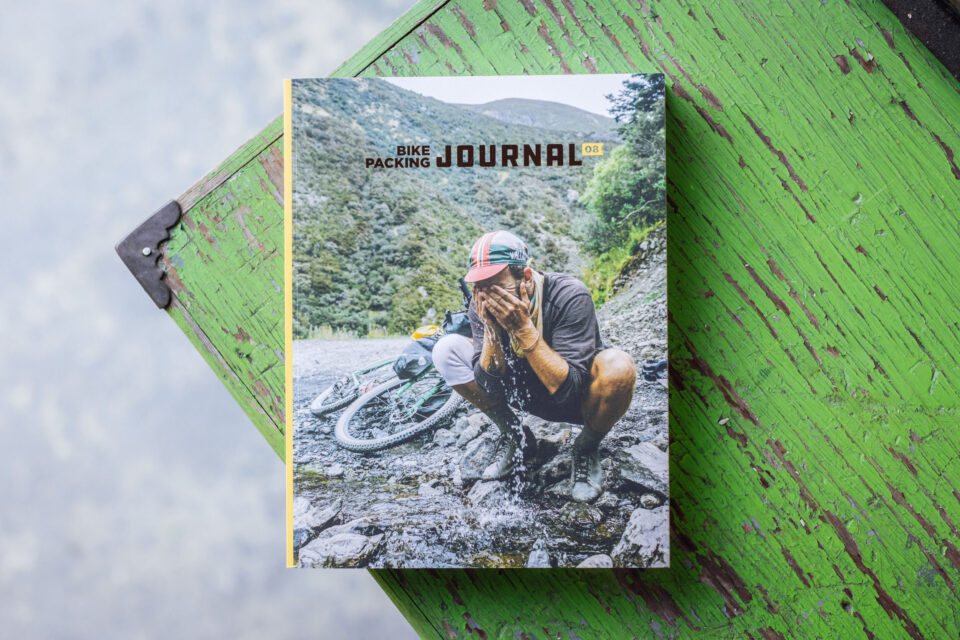

What started as a night owl’s bag-making hobby is now a full-time gig for former carpenter and bikepacking enthusiast Sam Lutz. During a visit to Northwest Arkansas, we caught up with Lutz at his first-ever shop space in Fayetteville. Check out our photo tour of the Buckhorn Bags shop and learn more about the maker behind the brand here…

If you’ve read anything about the bike scene in Northwest Arkansas, you’ve probably heard about the fairy tale transformation of Bentonville, its deep Walmart pockets, its meteoric rise as a mountain bike metropolis, and its oft-glorified role in transforming the region into something of a cycling snow globe. But there’s more to this not-quite-Southern, not-quite-Midwestern state than Bentonville and its bike boom, and in early fall, I went to the region to see for myself.

Before Bentonville’s big push to brand itself as the self-proclaimed “Mountain Biking Capital of the World,” I can’t say I knew much about Arkansas. No offense to our Arkansan (Arkansian, Arkansawyer?) readers. I knew about The Ozark Mountains; Arkansas is the Natural State, after all. I had heard about The Little Rock Nine and the pivotal civil rights moments that played out in Arkansas’ public schools. I had seen quirky roundups of quintessential Arkansas experiences, like eating Possum Pie and witnessing the World Championship Rotary Tiller Races. Yet I’d seen few stories that gave voice to the people who call the state home.

Sam Lutz is one of those people. Lutz is the owner and operator of Buckhorn Bags in Fayetteville, Arkansas. I first heard about Buckhorn Bags when Cass wrote this review and interview back in 2021, but I knew from following the brand that a lot had changed since then.

It is scorching hot when my plane touches down at Northwest Arkansas National Airport in late September. Cows are grazing in the pastures surrounding the runway. Instead of heading north to Bentonville, I point the rental car south to its bigger sister city, Fayetteville (pop. 95,230), home of the University of Arkansas. I pass a Walmart and turn onto S. Government Ave. Lutz’s truck is parked in a driveway beside a green building with a pink door. An unassuming brown stucco building with a Buckhorn Bags sign is tucked behind. If you didn’t know it was there, you’d miss it altogether. Lutz and his dog, Chief, greet me at the door, and we shuffle into the brightly lit—albeit stifling—shop.

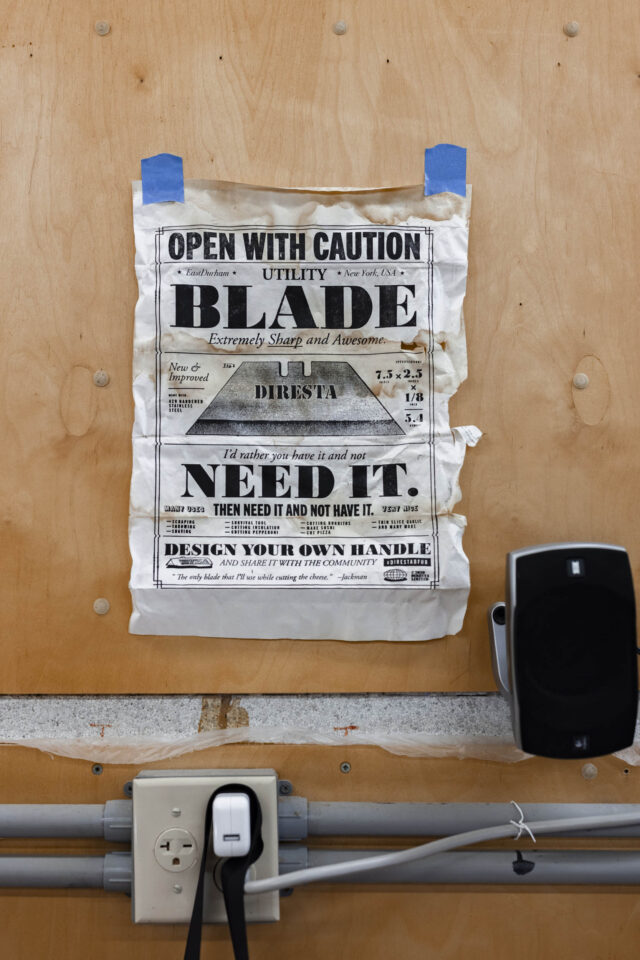

“It’s 100% concrete. I don’t have heat, air, or plumbing, so it’s cheap, which is great,” says Lutz.

For his first shop, cheap was all he needed. That, and some electric to run the sewing machines. He’ll order down pants for the winter, he says. The concrete slab makes sewing in the winter feel like sitting in an ice box.

Otherwise, the shop is the perfect stepping stone for Lutz, who made the leap to full-time bag making last year. The 1,800-square-foot space is, he admits, pretty big for a one-man brand, but he plans to grow into it. The location is ideal. It’s about 3.5 miles from his house and just off the Razorback Greenway, a 40-mile shared-use trail that connects Fayetteville to Bella Vista north of Bentonville. A quarter-mile in any direction, Lutz can be at the downtown square, the university campus, or High Roller Cyclery, one of his favorite bike shops. To get his mountain bike fix, Lutz need only hop on the greenway and ride a few miles to the base of Mount Kessler, a city-owned chunk of land with some 17 miles of narrow, handcut technical singletrack. Beloved by Fayetteville’s old-school riders, Kessler’s trails feel surprisingly remote given its proximity to downtown Fayetteville.

Lutz loves being a part of the growing cycling community in Northwest Arkansas. It’s not something he noticed as a kid when he was backpacking around the Ozarks or during his college days at the University of Arkansas. Back then, he was a rock climber, and he spent most of his days leading sport lines at Lake Lincoln and Horseshoe Canyon Ranch. Originally enrolled in the university’s engineering program, Lutz dropped out of college after five semesters. Maybe it was his penchant for dirtbaggery. Maybe it was the ADHD medication he stopped taking. Either way, says Lutz, he has always known that learning through books and exams was never his style.

“I’ve always had a base curiosity for how things work and why they are the way that they are, and in general, learning in a traditional sense didn’t fit me super well,” he says. “I learn really well by doing and seeing.”

After college, Lutz spent the better part of a decade working as a carpenter. At first, he specialized in trim and finish work, eventually landing in custom cabinetry which, he says, “is a bit like Tetris.” He loved that. After a brief stint of living and working as a carpenter in Colorado, Lutz and his wife moved to Wichita, Kansas, for her last years of medical school. It was here that bikes found Lutz in a big way.

Lutz had always had a bike in his life. In high school, he bought a ruby red and black 2006 Specialized Rockhopper Comp with lawn mowing money. It had disc brakes and flame decals, “which is really heinous,” says Lutz, but he rode it for years. In truth, he always had interest in cycling, he just didn’t have the financial means to get a proper bike. That is, until he moved to Wichita and started working part time at a bike shop. The shop carried Giant and Salsa and Waterford/Gunnar Cycles. Lutz first bought a Giant TCX drop-bar cross bike but later went all-in with a Salsa Warbird and Deadwood SUS 29+.

In the summer of 2019, Lutz and his wife moved to Albuquerque for her family medical residency. For Lutz, it was like moving to a playground for bike lovers. By then, Lutz—an ever-tinkerer—had started sewing fanny packs and frame bags for himself and his friends. Back then, he considered himself a backpacker, not a bikepacker, and he thought it’d be cool to get into ultralight backpacking.

“When I started looking into lightweight gear, I thought ‘holy smokes, who has $700 for a tent?’” Lutz remembers.

So instead, he decided to figure out how to make the gear himself. He asked for a sewing machine for Christmas, and his sister bought him a cheap Brother, the kind you might find at Costco, which wasn’t great but it was enough to get him going. Early on, he sourced most of his fabric from the local surplus store, which had, among many other things, random scraps of Cordura and foam. He learned to sew from trial and error, doing a lot of math, and going down the deep dark rabbit hole that can be a Reddit thread.

Around the same time he got his first sewing machine, Lutz had come across the site and started toying with the idea of bikepacking. It seemed like such a natural fit. Camping and riding bikes with friends—what more could you ask for? He bought a Revelate Sweetroll and a Tangle half-frame bag and, like a textbook, he studied both of them stitch by stitch, breaking down what he liked and didn’t like about their build and design. Then he made his own frame bag.

Within the first week of moving to Albuquerque, Lutz packed his Deadwood, his homemade frame bag, and that Revelate Sweetroll into his car and drove north to Santa Fe to participate in his first-ever bikepacking trip, led by Bailey Newbrey of Sincere Cycles. The trip was promoted as a chill sub-24-hour overnighter up to the Winsor Trail and back, but Lutz was nervous. The only bike riding he’d done had been at 1,300 feet above sea level. In Kansas, he says, you can ride 40 miles and never do more than a few hundred feet of climbing. But Santa Fe sits just above 7,000 feet of elevation, and the route they’d be riding went up to 10,000 feet.

“It’s only 17 or 20 miles to get up there but I was just dying, sucking wind. I couldn’t breathe. It was my first trip, so I had way too much stuff,” he says. “I just remember this guy riding up past me on this nice Cutthroat and he goes, ‘Hey, you have one more gear,’ and ‘I was like, no dude I don’t have any more gears,’ and he goes, ‘Yes you do, you can always walk!’ I just remember thinking maybe this bikepacking thing isn’t for me, this is freaking hard. But six months later, I did that whole loop and some extra singletrack in a day and had a blast.”

Lutz kept coming back and riding with Bailey and the Sincere crew. They went on bikepacking overnighters almost every month. Eventually, Lutz made some frame bags for a tandem Bailey had at the shop. Bailey thought they were good and told Lutz he should make a go of it. At the time, Lutz was working 40 hours a week as a carpenter for the University of New Mexico. He started sewing every day after work, sometimes stitching together new designs well into the wee hours of the morning.

Eventually, he upgraded his little Brother sewing machine for a 1953 German-made Pfaff 1245 he found on Facebook Marketplace for $500. He nearly pulled his back out loading the 84-pound hunk of metal into his car, but it was worth it. His first universal product was the Conejo, a fanny pack that doubled as a handlebar bag. Then he made the Rattler, a stem bag he designed with three rounded corners. He says it’s always been important to him to not simply “copy and paste” other brands’ designs but to think critically and add his own unique spin when pattern drafting.

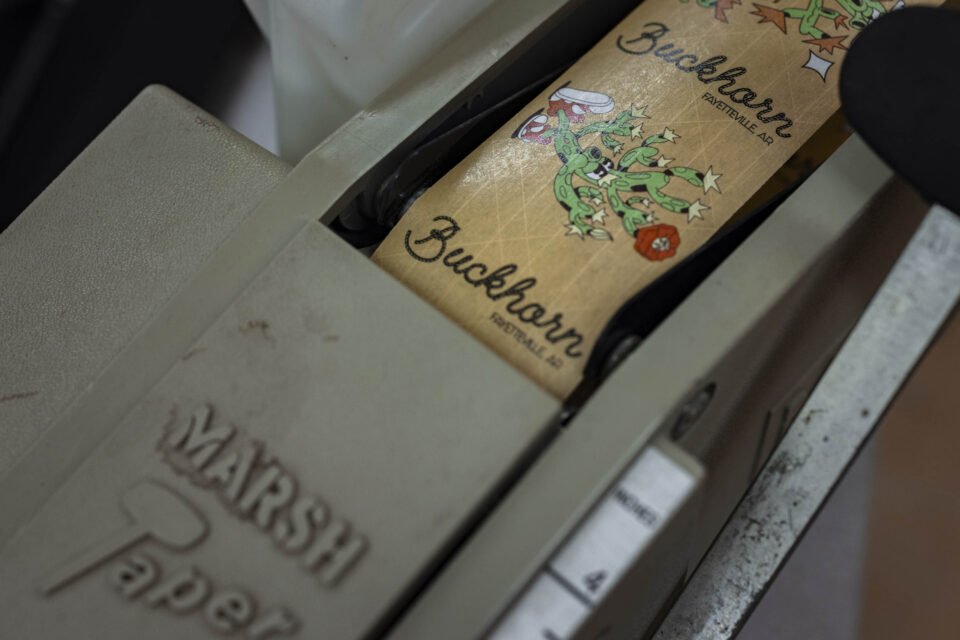

Sincere Cycles and the Broken Spoke were some of his first bike shop dealers. Lutz loved the community-first cycling scene and the western landscapes where he rode so much that he named his brand Buckhorn Bags after the cylindropuntia acanthocarpa, or buckhorn cholla, that is ubiquitous throughout the desert west. With every product he made, he backed it with a lifetime guarantee; Lutz will repair every piece of gear he makes, always, because it’s the right thing to do.

“I’d much rather repair something than have you replace it,” he says. “I want to offer good customer support and a good product that people can depend on.”

In addition to lifetime repair work, Lutz has built his brand around domestic sourcing and manufacturing. With the exception of velcro and plastic hardware, everything else Lutz uses for Buckhorn bags comes from the States. He sews primarily with X-Pac and waxed canvas, which he sources from a nearly 100-year-old mill. And he says he’s slowly but surely transitioning to PFAS-free silicon fabrics to reduce his environmental impact.

The first years of Buckhorn, Lutz stuck with making fanny packs, stem bags, and custom frame bags. But lingering over him like a persistent rain cloud was the top tube bag, a pattern he couldn’t perfect. Some of that was a math problem. Some of that was a sewing machine problem. At his shop in Fayetteville, Lutz shows me a half-dozen early iterations of his top tube bag design, some wonkier and floppier than others.

“The top tube bag was so elusive to me, and it was so annoying,” Lutz remembers. “I really wanted to get it dialed in, because you don’t have to be a bikepacker to use it, and they fit on anyone’s bike. But really, until I moved here and got a cylinder arm sewing machine, I couldn’t get a pattern figured out to be able to produce consistent, repeatable, accurate, finished products.”

After Lutz’s wife finished her residency in Albuquerque, the couple decided to move closer to family in a place with easy access to the outdoors. Fayetteville checked both of those boxes. Lutz’s sister lives in town, and his family is a few hours’ drive north in Kansas City. Plus, the Walton family has been sinking millions of dollars into building trails. What better place for an up-and-coming bike bag maker to set up shop than an up-and-coming region building its identity solely around bikes?

“We don’t have the elevation of the mountain ranges like you do out west. We don’t have the same volume of public land, but we have an awful lot of those things, and it’s a pretty good place to be,” says Lutz. “Even if all the mountain bike trail money hadn’t been spent here, this is still a solid place to live.”

Sitting in his spacious shop doling out head pets to his shop doggie, it is clear to me that at the root of Buckhorn Bags is a deep abiding love both of cycling and of creating. Lutz is not shy about professing his respect for other cottage makers; on the day I meet him, he’s sporting a Monē Bikes T-shirt and a pair of Melanzana crew socks.

Lutz’s bags are gorgeously crafted in beautifully vivid earthen tones and subtle pops of color. The man is nothing short of a perfectionist, and it’s clear that he won’t release a new product until he has thoroughly vetted his patterns. As a fellow easterner who has a soft spot for the desert, I don’t mind that his brand still pays homage to his time out west. I think we can all expect to see Lutz integrating elements of his new Ozark home into his brand and products.

No doubt, Buckhorn Bags has come a long way in just a few short years, and his transparency about the process makes me respect him even more. As a self-taught creative, his journey feels so relatable to me. His story is a reminder that all good things come with time and patience, but that there is no substitute for putting in the work. It’s a reminder, too, to keep chasing your curiosities.

Before I head out, I snap some photos of Lutz’s Salsa Fargo since, like me, he’s swapped out the drop bars for flat bars. I haven’t seen anyone else rocking a flat-bar Fargo, so I’m including his Fargo build below as well as some detail shots.

- Frame: 2019 Fargo (Large)

- Fork: Monē Bi-Plane

- Shifter/Mech: XO1 Eagle

- Cassette: XX1 10-50

- Cranks: RF Turbine 175mm

- Chainring: Absolute Black Oval 34t

- Brakes: Shimano SLX BR-M7100

- Rotors: Shimano SM-RT86 180mm

- Headset: King

- BB: White Industries

- Stem: RF Turbine 70mm -6*

- Bars: SQ Labs 30X Med Rise

- Grips: Ergon GA2 Fat and Cane Creek Ergo Bar Ends

- Seatpost: Lynskey Ti Setback

- Saddle: Brooks C17 Carved

- Hubs: Onyx Classic and SON 110

- Rims: Whisky No.9 36W

- Tires: Mezcal 29 x 2.6

- Pedals: OneUp Aluminum Flats

- Accessories: Sinewave Beacon V2, King Cages, Wahoo Roam

- Frame Bag: Double Decker Framebag or Halfie Framebag

- Accessory Bag: 8″ Top Tube Bag

- Handlebar Bag: Prototype Carradice style handlebar bag

Keep an eye on more good things to come out of Northwest Arkansas’ only bag maker! And many thanks to Lutz for the conversation and the kombucha. To see more from Buckhorn Bags, click here.

Further Reading

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.