A Decade of Sklar: Building a Bike Brand

On the heels of Sklar’s 10th anniversary and relocation to California, we recently stopped by Adam Sklar’s new shop to take a deep dive into the last decade of business, explore the Oakland space, and learn more about his transition from US-made custom frames with a two-year waitlist to Taiwan-made production bikes. Find all that, a peek at a few of Adam’s bikes, and loads of photos from Miles’ visit here…

PUBLISHED Mar 6, 2024

Adam Sklar was intrigued by how things worked as a kid, often taking stuff apart to discover their inner workings. Growing up in Boulder, Colorado, you might expect him to have a childhood full of mountain biking, but his parents didn’t ride much, so instead, he spent his time ski racing in the winter and backpacking in the summer. All his friends were mountain biking in high school and insisted he join them. After some hesitation, Adam borrowed his mom’s old road bike and converted it into a fixie, which was officially his first bike.

He had a knack for figuring out how things worked as he started a side hustle based around his new pastime. He began buying old road bikes, which Adam now realizes were probably beautiful classic lugged frames, and would convert them to fixies using cheap wheelsets. The local college kids were his primary customer base. Around the same time, Adam became obsessed with mountain biking and used his fixie-flipping money to buy his first mountain bike. “It was a Specialized Rockhopper,” Adam shared. “But back then, it wasn’t cool.” At this time, his friends were getting into rigid, single-speed 29ers, so Adam picked up an IRO Model 19, which also happened to be the first bike he built from the frame up. Interestingly, Adam didn’t work in a bike shop to learn these skills but figured it out through Sheldon Brown’s resources, trial and error, and a helpful mechanic in Boulder.

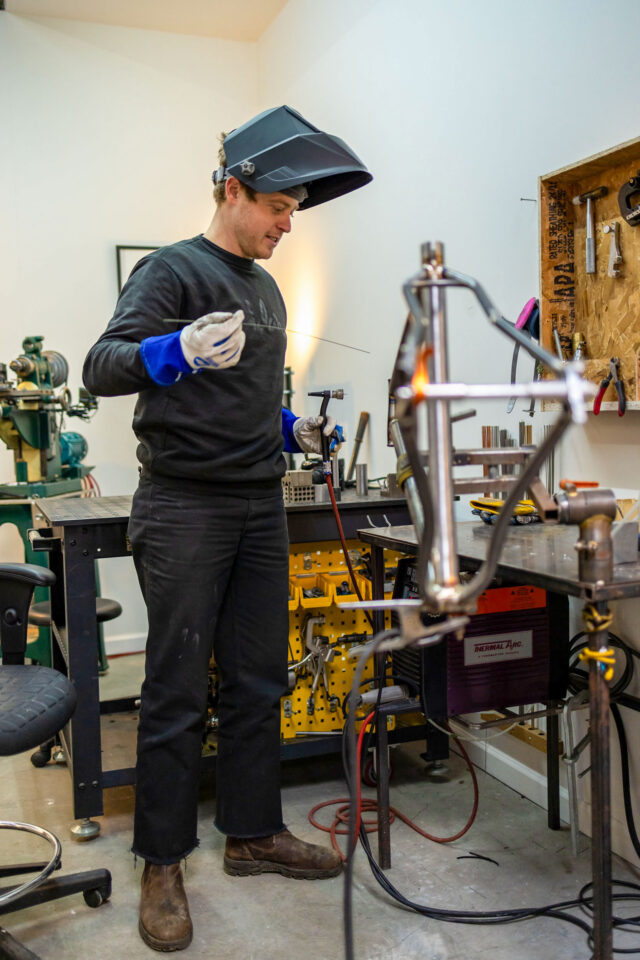

In 2011, Adam enrolled in mechanical engineering school, which is where his framebuilding story really started. At the time, a friend suggested that he make a bicycle frame, and Adam hadn’t even considered that as an option, but he decided he would. Adam dug into the MTBR forums, bought what he thought he needed to make a frame, and, during his freshman year winter break, tried to make a frame in his parent’s garage. “I stuck it together, but it wasn’t rideable by any means,” Adam said. He showed Walt Wehner at Waltworks the frame, who said, “That sucks,” and gave Adam a brazing lesson.

After building a few more frames with his new understanding of brazing, Adam discovered that the person who ran the machine shop on campus used to make mountain bikes in the 70s and 80s. He took Adam under his wing and gave him a job in the machine shop, and Adam started helping other students with their senior projects. But because they didn’t need Adam’s help, he used all of their scraps to make bicycle tools—some of which he still uses today. Adam rented a corner of the machine shop, which became his first real shop space.

This was all happening while Adam was in school and was also working a shift or two a week at a local engineering firm focusing on product design. That experience was invaluable, as these days, Adam is regularly sending engineering drawings away to be manufactured by someone else. He has saved so much time and money being able to create part drawings himself, and he was also offering that as a service to other bike brands for a while, which played a part in Skar’s recent transition to production bikes. “The fun part is going back and forth with the factory, designing dropouts, and figuring out exactly where the bosses need to be,” Adam explained. “Figuring out freight, where the text needs to be on a box, and marketing isn’t as fun. I really enjoy the design part.”

Adam graduated in 2015 and celebrated with friends on a bikepacking trip on the Colorado Trail, everyone riding bikes he had built. He was working at the engineering firm full-time at this point but was getting phone calls about bikes more and more. He felt increasingly distracted at work. After returning from the Colorado Trail trip, his boss took him aside and told him he needed to choose between the firm and framebuilding. Adam decided to give framebuilding a shot for three months, and the first thing his boss did was order a bike through him. “That was a nice thing for him to do. It was a really good push.” That marked the beginning of full-time framebuilding for Adam, and it hasn’t slowed down for the past seven years.

Custom, Small Batch, and Production

The brand took off in 2016 when Adam went to the North American Handbuilt Bike Show (NAHBS) and got enough attention to take full-time framebuilding seriously. He returned to NAHBS in 2017 and won the Best Mountain Bike award, further solidifying his decision to start a bicycle brand. The extra attention also meant the Sklar waitlist jumped to over a year and never went down. Adam explained that meant designing and fabricating around 50 frames each year, tens of thousands of dollars in deposits, and communicating with customers waiting for the next design slot to open.

Although framebuilders told Adam this was the best-case scenario, he found it draining, especially from the customer service side. “Being young and excited meant little work-life balance, which led to some burnout,” Adam shared. He felt for the customers who eagerly paid for a deposit, only to have to wait for months before starting the design process. Getting to a waitlist that long was part of Adam’s 10-year plan, but it came in just three.

Adam launched his first small-batch, non-custom bike in 2019. The Sweet Spot was an all-mountain hardtail MTB inspired by the previous decade of riding bikes and framebuilding. In many ways, it was also a case study for production frames. Adam explained that it got to a point where his customers, especially those buying hardtails, wanted the Sklar aesthetic, component compatibility, and progressive geometry he was known for but weren’t as concerned about fully custom sizing. He would build 15-20 Sweet Spots each year, which kept up for around four years. “Instead of a year’s lead time, it was three, and I built them in batches of four,” Adam said.

Around the same time the Sweet Spot was launched, Adam was thinking more about Taiwan-made production bikes. Up until that point, everything was handmade by him in Montana. The Super Something gravel bike kickstarted Sklar’s production bike story, and the story behind how he came up with the name is almost as silly as the name itself. He was visiting his friend Hubert of Madrean Cycles in Tucson with Ronnie Romance and Jordan Gomez (who now works for Adam). Sitting around one morning drinking coffee, Adam said the four of them needed to create a name for his first production bike. They landed on “Super Something” not because it was thought provoking or edgy, but because it was “the dumbest name ever, but it’s so stupid we used it,” as Adam puts it.

The first batch of Super Something gravel bikes shipped in 2023, marking a significant milestone for the Sklar brand and providing the opportunity for people to get a Sklar who might not have previously been able to. On paper, it’s not hugely different from other fully rigid gravel bikes on the market, with geometry that falls in between a relaxed drop-bar mountain bike and a racy gravel bike, modern specs, and plenty of clearance for 700 x 55mm or 27.5 x 2.1″ tires. This was also when Adam decided to stop taking custom frame orders until his queue got to zero, at which point he’d reassess. Adam hasn’t taken any custom orders since early 2019 and has no plans to change that.

The next production model in the Sklar lineup, the Tall Tale, is heavily inspired by the US-made Sweet Spot. Like the Super Something, the Sklar Tall Tale packs everything Adam has learned about progressive geometry and frame design into a versatile steel hardtail. It features Sklar’s trademark curved/ovalized top tube, an in-house designed chainstay yoke, asymmetrical chainstays, size-specific fork travel ranging from 130mm to 150mm, and a frame optimized for 29 x 2.6″ tires. At the time of my visit, production samples hadn’t arrived yet (they since have), but Adam was able to show off some paint samples. He told me he named them during Thanksgiving and decided on Pumpkin Pie (orange) and Kale Salad (green). The Tall Tale will be offered in four sizes, in complete builds and as a frame-only. It should be available this summer.

Next will be a production version of the PBJ (Performance Basket Jammer) based on the small batch of US-made versions Adam offered in 2023. It’s modeled after a prototype he made for himself in 2019—a rigid or short-travel mountain bike, all-rounder, or ATB. Adam describes it well on his site, “It may look simple, but you can always count on it to get the job done.” He’s planning to have the PBJ available by the end of 2025, which means three production Sklar’s will be released within three years, and this is no accident. According to Adam, people have been confused about what Sklar is, with a single production model officially out in the wild. Adam said, “People have been like, oh, that framebuilder made a production bike; that’s cute. But I’m going to be a bike brand by the end of this year, which is cool.” I find this transition fascinating to watch unfold. Adam built Sklar up to the point that most framebuilders can only hope to get to and is now rebuilding as a production bike brand that’s far more accessible for folks without deep pockets.

I was curious how Adam found the transition to Taiwan-made frames after focusing on custom frames for so long, and like most cycling industry stories, it started with a friend willing to lend a hand. Ryan Krueger, co-founder of Esker Cycles, was living in Bozeman and was a good friend of Adam’s. He eventually introduced Adam to the agent Esker worked with, who also happened to work with almost all of the small boutique bike brands in the US. In more ways than one, Adam’s experience as a mechanical engineer and framebuilder made the transition to production bikes relatively easy.

He had already worked with overseas manufacturing as part of his engineering gig, so creating technical frame drawings wasn’t new for him, and designing and building hundreds of custom frames meant deciding on tube thickness, whether the fork crown would clear the downtube, and details like cable guide position weren’t unexpected hurdles. “I was working on a new fork, and they sent me a drawing with the bosses in the wrong place, so I sent them a 3D drawing showing exactly where they should go,” Adam explained. “Some people have complaints about Taiwan manufacturing, but in my experience, the problem is you get exactly what you ask for. They are incredibly thorough about communicating everything, and you sign off on the drawings, so it’s important to get it right.”

Looking Forward

I asked Adam if he missed custom framebuilding, and after a slight pause, he responded simply, “No,” followed by a laugh. Moving forward, Adam fills any custom framebuilding urges by designing and fabricating small batches or one-off bikes to help shape future production bikes. He also shared that it wasn’t the custom part of framebuilding that he was obsessed with, though it allowed him to talk to hundreds of people and gave him a good understanding of what people want. “When I started, you either worked in a bike shop and started building frames, or you were a fast bike racer, and those were the only two ways to be legit in the bike industry. I just wanted a nice bike for me, as someone hasn’t worked in a bike shop and was never fast, which it turns out is almost everyone who rides a bike,” Adam said. “I’ve been joking that my dream goal for Sklar is that someday they end up on a college campus with all the parts stolen off of it. Someone gave it to their kid, the kid lost the key for his bike lock, and it lasted an entire generation and is still there.”

I asked Adam where he sees Sklar in 10 years, and he responded, “I don’t want to be a huge company. I’m still figuring the brand out. Ideally, we’re selling 1,000 frames a year, and there comes a point where I will have to offer (Taiwan-built) complete bikes. I could see having like 3-4 models at a time, that are pretty much the bikes I want to ride.” For now, Sklar operations are split between Adam’s new space in Oakland, California, where the prototypes and small-batch frames are made, and Bozeman, Montana, where Jordan assembles and ships production bikes.

Like others, I wondered why Adam moved to California, which, from an outsider’s perspective, seemed quite unexpected. It turns out that Adam has always wanted to live in California, craving diversity and culture that he wasn’t getting in Bozeman. He’s also impressed by Oakland’s balance of city and nature, sharing the example of riding five miles from the industrial area where his shop is to stunning eucalyptus forests, ocean views, and flowy trails. “I can ride trails out my front door and end it with a sandwich and natural wine at some hip bar. Life is pretty good.”

Sklar’s Oakland HQ

I had no idea Sklar’s new Oakland shop was based out of the same industrial metal building as Pass and Stow Racks, the beloved handmade rack company Evan Christenson visited last year. The large warehouse is also home to a custom furniture maker, a piano repair shop, and Billings Cycle Works, so it’s safe to say that creativity flows through its outdated cast iron pipes. The nearly 5,000 square foot space is packed to the brim with interesting handmade creations, from the vintage couch Adam found on the street to Erik Billings’ filet-brazed frames—one could spend days poking around its packed walls. I’ve never been so close to a life-sized version of Where’s Waldo.

Everyone I met during my visit was focused on their craft, but an unshakable feeling of comradery had me itching to make something with my hands. Matt Feeney was showing his new shop helper, Stevie, how to shape the top platform for a front rack, a wild process that had Adam and I in awe. Erik at Billings Cycle Works was replacing cables on a bike in his stand and is said to be one of the last mechanics in the area who will replace a bicycle tube for you.

Bicycles aren’t the only thing Adam has built over the years. He made all the fixtures and tables in his shop and did the same at the Bozeman space. Before Adam moved into his house in Bozeman, he had no real furniture, so he made most of it. “I didn’t have any stuff, but I like nice things, and it turns out I can’t afford them,” Adam shared. So he made everything he wanted. Something clicked when he walked into his living room and thought, I like everything in here. He compared that feeling to how people must feel when they get on a nice bike and how as a poor kid making nice bikes, he wasn’t able to identify with that.

These days, Adam likes to be surrounded by things that feel intentional, and furniture is an excellent example of that. Adam used a bike as another example: “It’s an intimate thing that you spend a lot of time on. It takes you to the top of a mountain, and then you look at it, and most bike people will look at their bikes and think, yeah, my bike is sick!” Adam thinks he nerds out about the history behind the Hans Wegner wishbone chair in his shop just as much as bike nerds talk about bikes. Having recently moved into his Oakland space, Adam has a laundry list of to-dos, including making picture frames for various pieces of artwork friends gave him. Thankfully, there’s a high-end architectural wood mill down the street with a dumpster full of offcuts that he will repurpose into frames—after he builds a few bikes, of course.

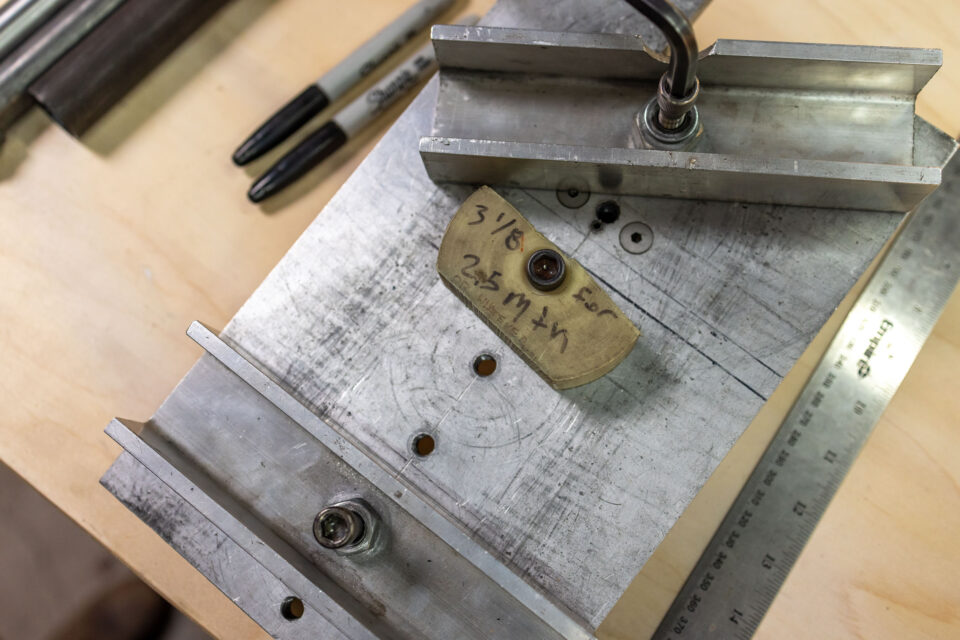

A decade of custom framebuilding means Adam’s shop has everything he needs to design and fabricate production bike prototypes. He’s been using a 3D printer to mock up the shape of ovalized tubes, confirming the inverse oval and the tube cuts he makes are correct. He’s still using a deburring tool he made in school after ordering the wrong-sized blades. Over the years, he’s also designed and made several of his own jigs and tube benders, including a nifty seat tube bender that he said was a big deal at the time. When everyone was getting into 29″ wheels and short chainstays, Adam was one of the only framebuilders with a seat tube bender.

Nowadays, it’s easy to go online and order pre-bent seat tubes or a seat tube bender of your own, but Adam sees this as a positive. Making framebuilding more accessible means “more weird small brands,” Adam explained, “which means more people looking for weird small brands. You’re buying the bike because of the story behind it. This road bike I’m building will be my first road bike ever. Most people wouldn’t come to me for a road bike. You wouldn’t come to me for a fat bike because I think fat bikes are stupid. But many builders out there love those things, so there’s lots to go around.”

Small-Batch Sklar PBJ

The PBJ, “Performance Basket Jammer,” will be Sklar’s third official production model. Like the bikes that came before it, Adam has been tweaking the design in-house and building prototypes to test out in the real world. As mentioned, the PBJ is a fully rigid or short-travel all-terrain mountain bike and is Adam’s favorite Sklar yet. It will have rocker-style dropouts, loads of mounts, and the same elegant ovalized tubing as the Super Something.

When Adam introduced the PBJ as a small-batch model three years ago, he gave the option to purchase it with a carbon fork because it saved him time and meant customers got their bikes quicker. When he tried his with a carbon fork, it resulted in a harsh and uninspiring ride quality. The prototype fork uses 1 ⅛” bent tube crowns for strength, 1″ blades for flex, and BMX-style dropouts.

Adam’s Panasonic MC 4500

I’m not sure whether Adam wanted me to take photos of his go-to commuting rig, but it was too cool not to include. His 1988 Panasonic MC 4500 is built with a swoopy handlebar, friction shifters, a Brooks saddle, a Pass and Stow front rack built in the same building, a Wald basket with a tote bag, and a Sinewave dynamo setup.

A One-Off Sklar Tall Bike

Adam made this one-off tall bike to ride at an upcoming group ride. Perhaps the most interesting detail is that it uses almost identical geometry to the PBJ but has a super high bottom bracket. I don’t think we can expect to see a production tall bike any time soon.

Adam’s 2019 PBJ Prototype

As mentioned earlier, Adam built his own PBJ in 2019, and it has become his favorite bike yet. This particular build is kitted out with some nice bits, including a Paul stem and brakes, a Crust Harvey Mushman Riser Bar, White Industries cranks, a dropper post, and a massive frame bag. Looking at this, I can’t help but think of Logan’s all-terrain bicycle (ATB) manifesto and how seamlessly the PBJ fits into that concept. Big tires, a big main triangle, and a fully rigid steel frame—what’s not to love? Production PBJs will have rocker dropouts but will otherwise look similar to this.

Adam’s Fixie

In 2019, Adam built himself a fixie as an end-of-year bonus, made from some tubes that had been collecting dust in his Bozeman shop. It was originally left raw but was finished with a fresh coat of Cerakote in 2020. While it’s a bit outside of Sklar’s regular programming, I appreciate how the overall aesthetic is so unmistakably a Sklar. Few brands can be identified without paint or logos on them, but that curved top tube, swoopy seat stays, and the clean lines are impossible to miss.

Final Thoughts

Adam’s story is quite unique. He’s gone from boutique US-made custom bikes and long wait times to US-made micro-batch frames, and now Sklar is officially a production bike brand. A decade of framebuilding alongside his mechanical engineering schooling has proven invaluable for this next phase. It has allowed him to get his bikes to more people without sacrificing the quality, attention to detail, and look that makes a Sklar.

Adam works closely with the family-owned factory in Taiwan that builds his bikes (in fact, he’s visiting them in person right now), and every model he releases will be based on production bikes he designs and fabricates himself in his Oakland workshop. The transition to production bikes means folks can get themselves on a Sklar for a fraction of the cost of a custom frame with shorter wait times, and each model is based on a successful custom framebuilding career, an obsession for design, and perhaps most importantly, regular people going on regular bike rides.

Further Reading

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.